MD-160KVA CNC Double Projection Guide Rail Welding Equipment Double Head Slide Rail Welding Machine

- $13500.00 / 1 - 4 sets

$13200.00 / 5 - 19 sets

$13000.00 / >=20 sets - 1 set

- Foshan Junwei Intelligent Machanical Equipment Technology Co., Ltd.

- Guangdong, China

- Ms Zou Judy

PRODUCT DETAIL

| Marketing Type: | 2020 new products | Video outbound inspection: | if |

| After-sales service provided: | Video technical support online support | type: | Pressure welding machine |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Applicable industries: | Hotels, Clothing Stores, Building Materials Stores, Machinery Repair Shops, Manufacturing Plants, Food and Beverage Plants, Farms, Restaurants, Household Use, Retail, Food Stores, Print Shops, Construction Engineering, Energy and Mining, Food and Beverage Stores, Others, Advertising company |

| Power (kW): | 200 | brand: | Junwei |

| Customized machine price: | to be negotiated | After Warranty Service: | 1 year |

| application: | Slider welding | Mechanical test report: | if |

| Origin: | Guangdong, China | Weight (kg): | 500 kg |

| MOQ: | 1 set | Main selling points: | competitive price |

| Input voltage: | 380V | feature: | high efficiency |

| usage: | Computer desk slide rail welding | Core component warranty: | 1 year |

| Package preview: | Showroom location: | not any | |

| port: | Foshan, China | Type of machine: | Pressure welding machine |

| Supply capacity: | 200 sets per month | product name: | Slide welding machine |

| Packaging Details: | Plywood boxes | Core components: | PLC, motor, pump |

| Warranty: | 1 year | Health status: | new |

| Model: | MD-160KVA |

product description

1. Special design of integrated tube cylinder to ensure welding stability

2. Spot welding and projection welding functions. 3. Computer control system, stable voltage and flow, multiple time periods

Discharge (MTD), yesEasily meet various work needs.

4. Can weld iron and stainless steel.

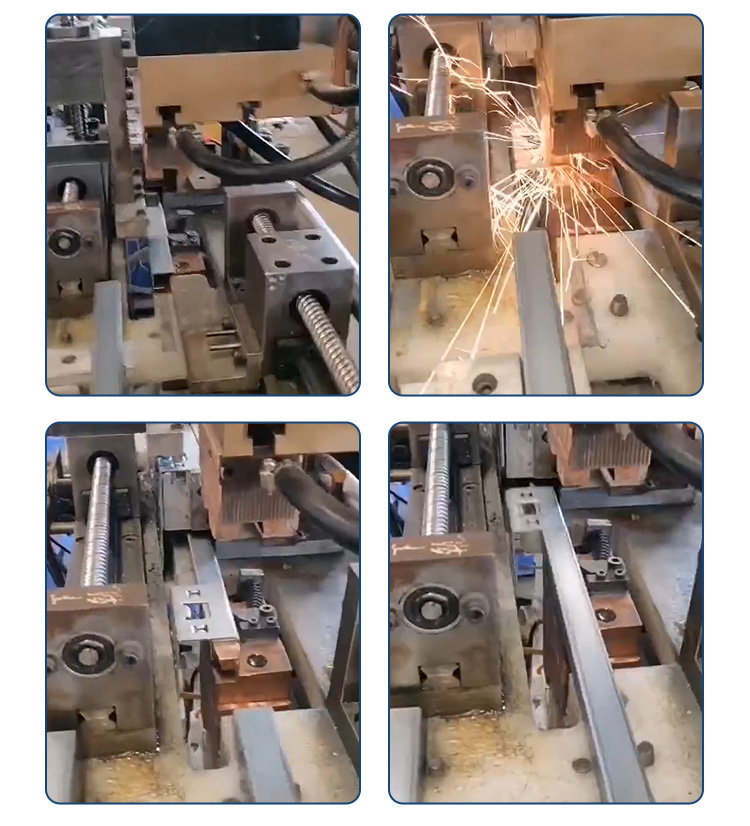

Sample display

product specification

Customized spot welding machine/pressure welding machine It is a customized machine from our factory. It is characterized by strong welding, beautiful welding shape, and can be operated by anyone. Safe and efficient. No need for welding rods or professional welders, cost reimbursement within 5 months at most, and 1-year warranty. If there are any problems, we will repair them for you free of charge except for human damage and our own reasons. Consumables are exhausted.

Welding head:Flexible adjustment, rare earth alloy copper, real material, wear-resistant and high-temperature resistant, long-lasting operation.

All-in-one machine:It is easy to maintain and easy to operate, even novices can operate it.

control box: CNC system, stable system, real-time monitoring, high-quality production.Foot switch: Autonomous control, simple operation, even novices can operate, safe and secure.

Pure copper raw material

Small resistance, less heat, good conductivity, long life (more than 5 years)

Technical discussions

The control of details determines the quality of products

precise measurement

Accurate measurementWorkpiece size is an important step in building a good machine

Model | Input voltage | Spin capacity kVA | rated frequency hertz | Rated working cycle% | Arm length mm | Electrode travel mm | Cooling water consumptionl/min | Maximum welding capacity (welding two pieces of mild steel) mm |

25KVA | 380V*3 | 25 | 50/60 | 50 | 350 | 50 | 3 | 1.0+1.0 |

40KVA | 380V*3 | 40 | 50/60 | 50 | 350 | 50 | 3 | 2.0+2.0 |

50KVA | 380V*3 | 50 | 50/60 | 50 | 380 | 60 | 4 | 3.0+3.0 |

63KVA | 380V*3 | 63 | 50/60 | 50 | 380 | 60 | 4 | 3.5+3.5 |

80KVA | 380V*3 | 80 | 50/60 | 50 | 400 | 75 | 5 | 4.0+4.0 |

100KVA | 380V*3 | 100 | 50/60 | 50 | 400 | 75 | 6 | 4.5+4.5 |

160KVA | 380V*3 | 160 | 50/60 | 50 | 400 | 75 | 8 | 5.0+5.0 |

200KVA | 380V*3 | 200 | 50/60 | 50 | 400 | 75 | 10 | 6.0+6.0 |

Provide non-standard customized services

Various welding equipment such as spot welding machines, projection welding machines, butt welding machines, automatic welding machines, semi-automatic welding machines, etc.

Can be customized according to workpiece requirements

VIEW MORE

YOU MAY LIKE

Other Products

-

Multifunctional electric heating welding machine price online purchase xy spot welding machine for home use$4400.00 - $4800.00 / set

Multifunctional electric heating welding machine price online purchase xy spot welding machine for home use$4400.00 - $4800.00 / set -

CNC multi-function pneumatic spot welding machine equipment$3300.00 - $3700.00 / set

CNC multi-function pneumatic spot welding machine equipment$3300.00 - $3700.00 / set -

DTN-200KVA Standard CNC Automatic Wire Mesh Lantern Cage Welding Machine Welding Machine$13000.00 - $13400.00 / set

DTN-200KVA Standard CNC Automatic Wire Mesh Lantern Cage Welding Machine Welding Machine$13000.00 - $13400.00 / set -

DTN-160 CNC Standard Multifunctional AC Wire Mesh Welding Machine Pressure Welding Machine$5000.00 - $5400.00 / set

DTN-160 CNC Standard Multifunctional AC Wire Mesh Welding Machine Pressure Welding Machine$5000.00 - $5400.00 / set