2x72 knife making variable speed belt sander max copper steel motor horizontal brass original type vertical material placement model

- $899.00 /set

- 1 set

- Zhengzhou Hanxiang Machinery Equipment Co., Ltd.

- Henan, China

- Ms vincy yuan

PRODUCT DETAIL

| Custom Support: | OEM, ODM; | grade: | DIY; |

| Rotating speed: | 2800 rpm; | Applicable industries: | belt sander; |

| application: | Copper, LRON, ferrous metals, brass, steel; | Grinder Type: | Horizontal belt grinder, vertical belt grinder; |

| Knife making and steel processing belts: | 2" X 82"; | Warranty: | 1 year; |

| port: | any port in China; | Maximum Motor Speed: | other; |

| Voltage: | 120/240VAC, 110V-230V; | Packaging Preview: | ; |

| Main selling point: | High security level; | strength: | 1.5KW; |

| Supply capacity: | 50 sets per month; | model: | 1.5KWTSSGJ0000001; |

| Packaging Details: | Standard export wooden box; | Energy source: | electrical; |

| Weight (kg): | 90; | Toothed rubber tires: | 30 cm; |

| type: | belt grinder; | current: | 3.5A/7.5A; |

| Dimensions (L*W*H): | 68*58*64cm; | place of origin; place of origin: | Henan, China; |

| payment terms: | L/C,D/P,D/A,T/T; | Rubber Contact Wheel: | PH 427 X 12"; |

product description

detailed picture

The double-layer frame makes it more stable.

The whole machine has an all-steel structure, and the surface is polished and sprayed, which is durable and durable.

Equipped with 1500w pure copper motor.

This super powerful motor runs smoothly and tracks very steadily.

Adjustable table. Adjust it to your needs to make it more convenient.

Product parameters

* The machine is all-steel structure, the surface is polished and sprayed, which is durable.

* Equipped with 1500w pure copper motor.

* Adjustable table.

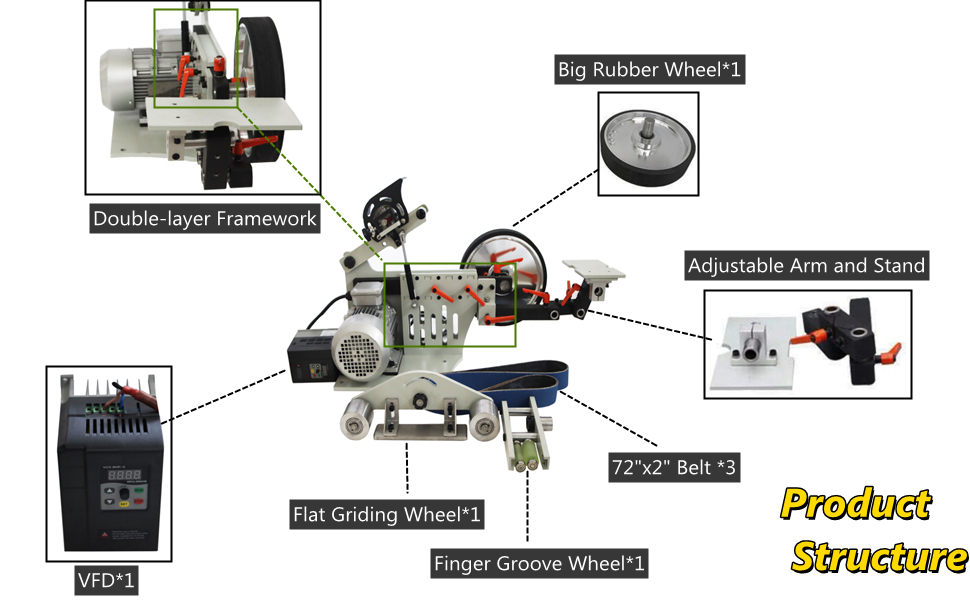

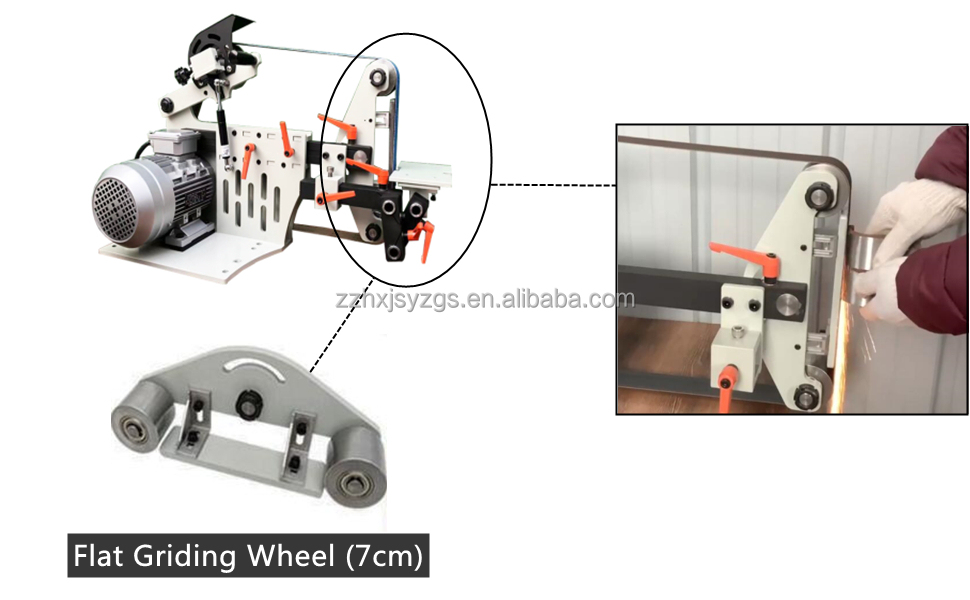

* It is equipped with three different grinding wheels.

* Equipped with 1500w pure copper motor.

* Adjustable table.

* It is equipped with three different grinding wheels.

Voltage | 220V | weight | 152 lbs / 69 kg |

Belt size | 72"inch*2inch/1828mm*50MM | pack | wooden box |

multipurpose machine

Multi-field application

Recommended Products

It comes with three different grinding wheels. The ideal machine tool for surface grinding, arc grinding and concave grinding.

Company Profile

Zhengzhou Hanxiang Machinery Co., Ltd. is a company integrating independent product design and sales. The company mainly sells agricultural machinery, belt grinders and other commodities, mainly exported to Europe, America, Southeast Asia and other places. It has established long-term and stable cooperative relations with many corporate users around the world, and has achieved a good reputation.

Product packaging

FAQ

Question 1: Is the pellet machine dry in and out?A: What we usually call dry in and dry out means that the raw materials can be processed directly. This is a misunderstanding. It is not really dry in and dry out, because the raw materials used contain a certain proportion of moisture. As long as the overall humidity is between 10% and 15%, there is no need to add water, and it can be done directly. If the raw material is very dry, you can spray a little water, a small amount, about 3%-5%, so that it can be well formed without affecting the storage.Question 2: Does the pellet machine have requirements for raw materials?Answer: Grain raw materials do not need to be crushed, but forage and straw must be crushed before processing. It is best to use powdered materials because the granules made from powdered materials are evenly nutritious.Question 3: Can we not use your motors and equip them locally?A: Of course, it is convenient for future maintenance, and it can also save freight! But our price is not the price of the motor! Our motors are all copper cores of 100% national standard regular manufacturers, the price is relatively expensive, and the quality is completely assured!

VIEW MORE

YOU MAY LIKE