42CrMo forged bars Alloy steel Factory direct sales

- $1050.00 / >=10 pieces

- 10 pieces

- Shandong Laboratory Metal Co., Ltd.

- Shandong, China

- Ms Sha Sha Cui

PRODUCT DETAIL

| Processing services: | cutting, punching, cutting | product name: | Steel Step Forging 1.6587 |

| Packaging Details: | Plastic Packaging | standard: | Chinese |

| place of origin; place of origin: | Shandong China | quality: | High |

| shape: | round | grade: | 18CrNiMo7-6 |

| expiration of pay: | L/CT/T (30%TT deposit) | delivery time: | within 7 days |

| delivery conditions: | Pre-hardened (28-36HRC ) | thickness: | 200-1000mm |

| Alloy or not: | alloy | Certificate: | ISO9001 |

| port: | Qingdao/Tianjin/Shanghai/Ningbo | Package preview: | |

| Supply capacity: | 2000 tons per month | Package: | Standard Shipping Packing |

| tolerant: | ±1% | MOQ: | 1 |

| Material: | 1.6587 | surface: | bright |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | brand: | LBR |

contact me for discount

Normalizing 18CrNiMo7-6/1.6587

1. Nominal normalizing temperature: 840-890°C

2. Keep warm for several hours

3. Cool in air

18CrNiMo7-6/1.6587 annealed

1. Nominal annealing temperature: 630-650°C

2. Slowly cool in the furnace

3. The maximum Brinell hardness is 229

18CrNiMo7-6/1.6587 quenched and tempered (QT)

1. Nominal hardening temperature: 830-865°C

2. Keep at this temperature and then quench in oil

3. Temper as soon as possible when the temperature is as low as the ambient temperature

4. Carefully heat the steel to the appropriate temperature selected with reference to the tempering chart or table

5. Usually the tempering temperature is 600°C, depending on actual requirements

6. Put the material out of the furnace and let it cool in the air

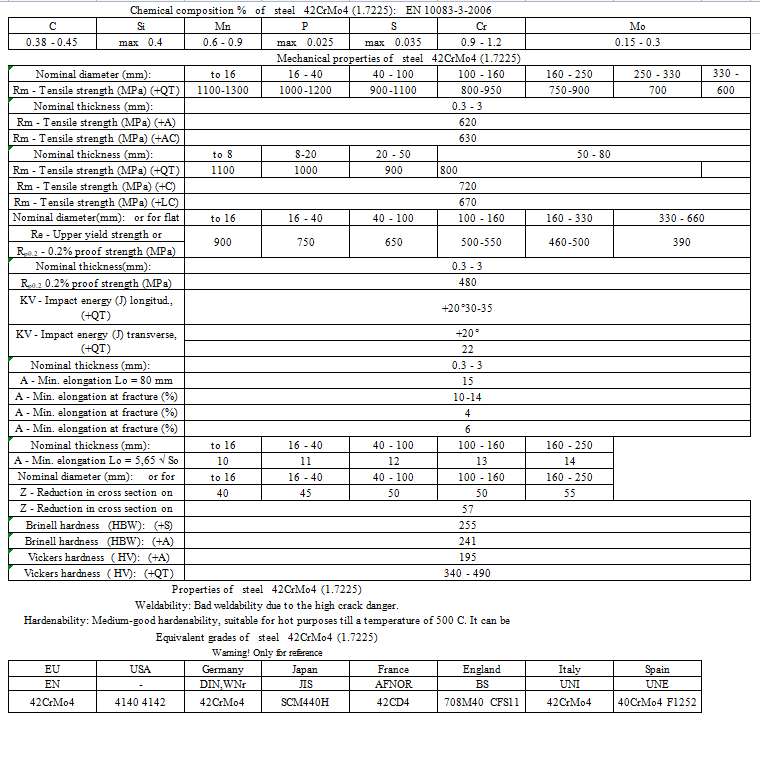

Mechanical properties (for reference only)

1. Tensile strength: 980-1270MPa

2. Yield point: 780MPa

3. Area reduction rate after breaking: 40%

4. Elongation after breaking: 11%

5. Impact test (+20°C): Longitud – 45~50J

delivery conditions

1. Shape: round/square/flat/shaft/roller/block

2. Surface state: black surface/bright surface

3. Heat treatment: normalizing/annealing/QT

4. Straightness: maximum 3mm/m (enhanced straightness can be provided upon request)

5. Length: 3000-5800mm is suitable for 20″container. Above 6000mm is suitable for 40″container

6. Granularity: 5-8 in line with ASTM E112-96

7. Typical hardness: HRC28-32

8. Ultrasonic standard: Sep1921/ASTM A388/EN 10228-3

9. Non-metallic inclusions: 2 max acc to ASTM E45 /K4≤20 acc to DIN 50602

10. Forging ratio: minimum 4:1

11. Marking: grade/weight/length/size/furnace number

contact me for discount

VIEW MORE