5 axis precision aluminum cnc machining Parts watch parts odm cnc steel case Cnc machining service

- $1.00 / 1 - 999 pieces

$0.89 / 1000 - 9999 pieces

$0.79 / >=10000 pieces - 1 piece

- Shenzhen Tontinco Co., Ltd.

- Guangdong, China

- Mr Lou Lu

PRODUCT DETAIL

| Packaging Details: | Each piece in bubble film/carton or wooden case | product name: | CNC parts |

| Material: | stainless steel, alloy | brand: | Tontinko |

| size: | custom size | port: | Shenzhen/Hong Kong/Guangzhou |

| color: | custom color | Key words: | watch parts |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Origin: | Guangdong, China |

| delivery time: | 10-20 days | Supply capacity: | 100,000,000 pieces per week |

| Package preview: | application: | mechanical watch | |

| QC: | 100% quality control | MOQ: | 1 |

| Surface treatment: | Anodizing/Grinding/Polishing/Painting/Electroplating |

If you need help, please contact us!

Strength factory, solemn commitment:

We will recommend the most suitable production process for you to reduce labor production costs and material consumption! To provide you with high quality and favorable price! Fast delivery! Guaranteed delivery time! Please rest assured that if the product does not meet the design drawings determined by both parties, it will be unconditionally returned and refunded, and corresponding compensation will be provided.

Click to view more CNC products

Advantage | One-stop solution for machinery customers: Provide production design, production and technical services, mold development and processing, etc. Rich experience in small batches and multiple varieties Extensive high-volume experience 29 years field experience, more than 80 engineers |

Approach | CNC machining. turn. Milling, stamping, sheet metal. assembly. Grinding, Wire EDM |

available materials | Stainless Steel Carbon Steel, Brass, Bronze. Iron, aluminum alloy, nylon, SPCC, SECC, etc..... |

material standard | national standard. ASTM, EN, DIN, JIS, BS, ANSI. SAE |

tolerant | ± 0.002mm |

surface treatment | Anodizing, sand blasting, electroplating. powder coating. Liquid painting, PVD, electrolytic polishing, wire drawing, galvanizing, laser engraving, silk screen printing, etc. |

file format | Solid Works, Pro/Engineer, AutoCAD (DXF, DWG), PDF, TIF, etc. |

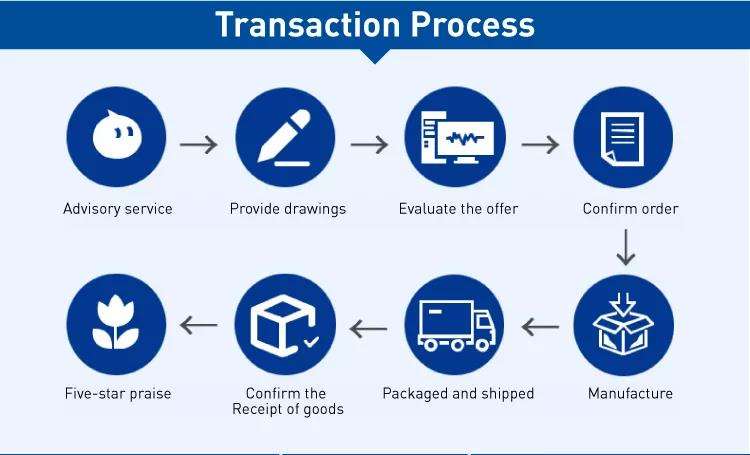

inquiry | Customer inquiry→engineering communication→cost analysis→sales analysis→quote to customer » Only 1-3 working days » Submit RFQ with full commercial terms |

order management | CRM system → open order confirmation → logistics arrangement. » Production L/T: 2-4 weeks » Weekly open order confirmations » Customers preferred 3PL services |

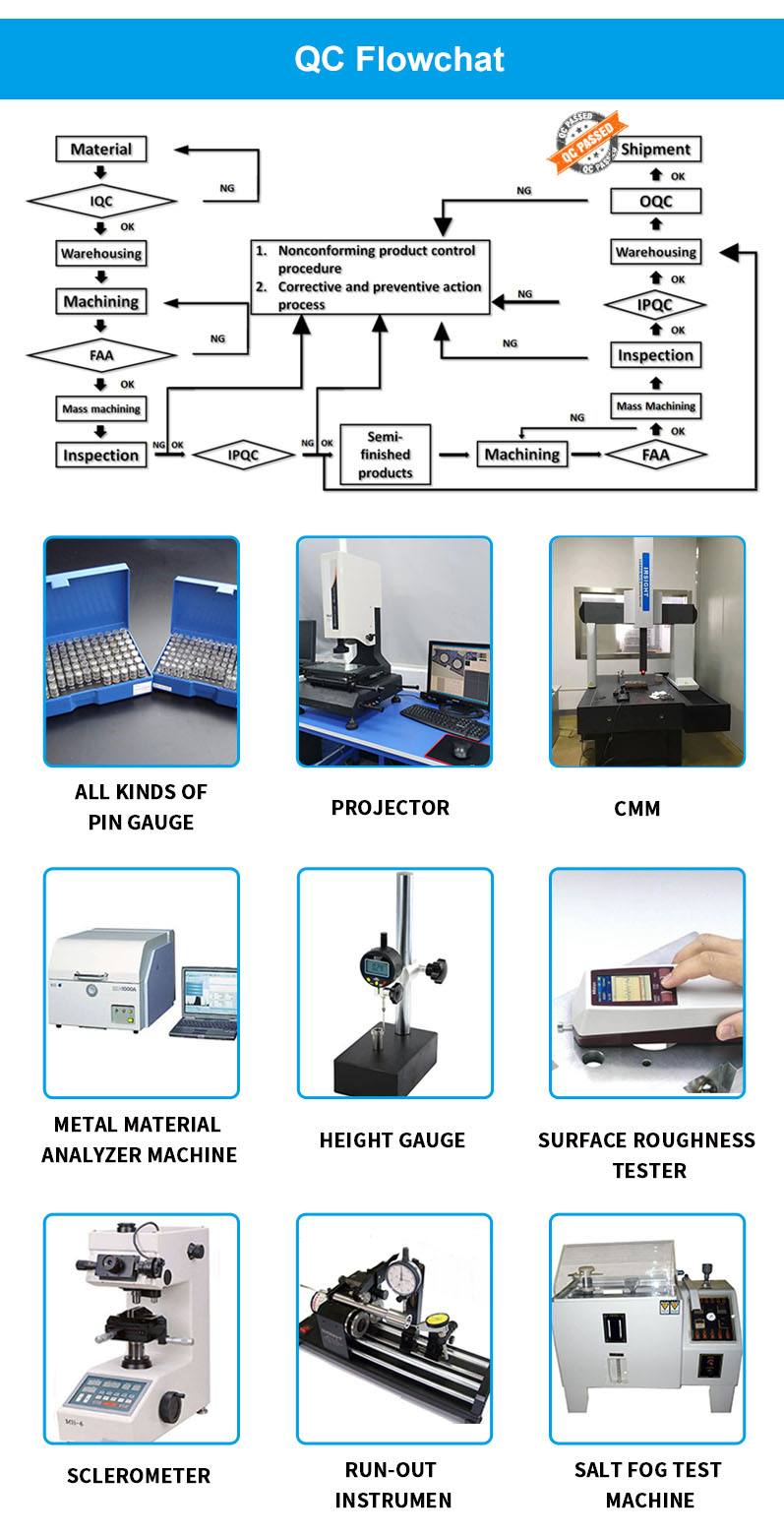

QC | Certificate: RoHS, 1809001:2015, SGS. 100% QC quality inspection before delivery, quality inspection sheet can be provided IQC → IPQC → OQC/FQC → Quality Complaint Feedback → Audit and Training. » Factory audits and certifications from world-renowned companies » Strict quality management procedures with traceability |

Testing Equipment | Coordinate Measuring Machine; Tool Microscope; Multi-joint Arm; Automatic Height Gauge; Manual Height Gauge; Dial Indicator; Marble Platform; Roughness Measurement |

application | Aerospace/shipping/subway/motorcycle/automotive industry. instrumentation. Office equipment, home appliances. medical equipment, telecommunications, electrical and electronics, fire detection systems, etc. |

24-hour online quote service Get a free quote

>>Let's talk>>

>>Let's talk>>

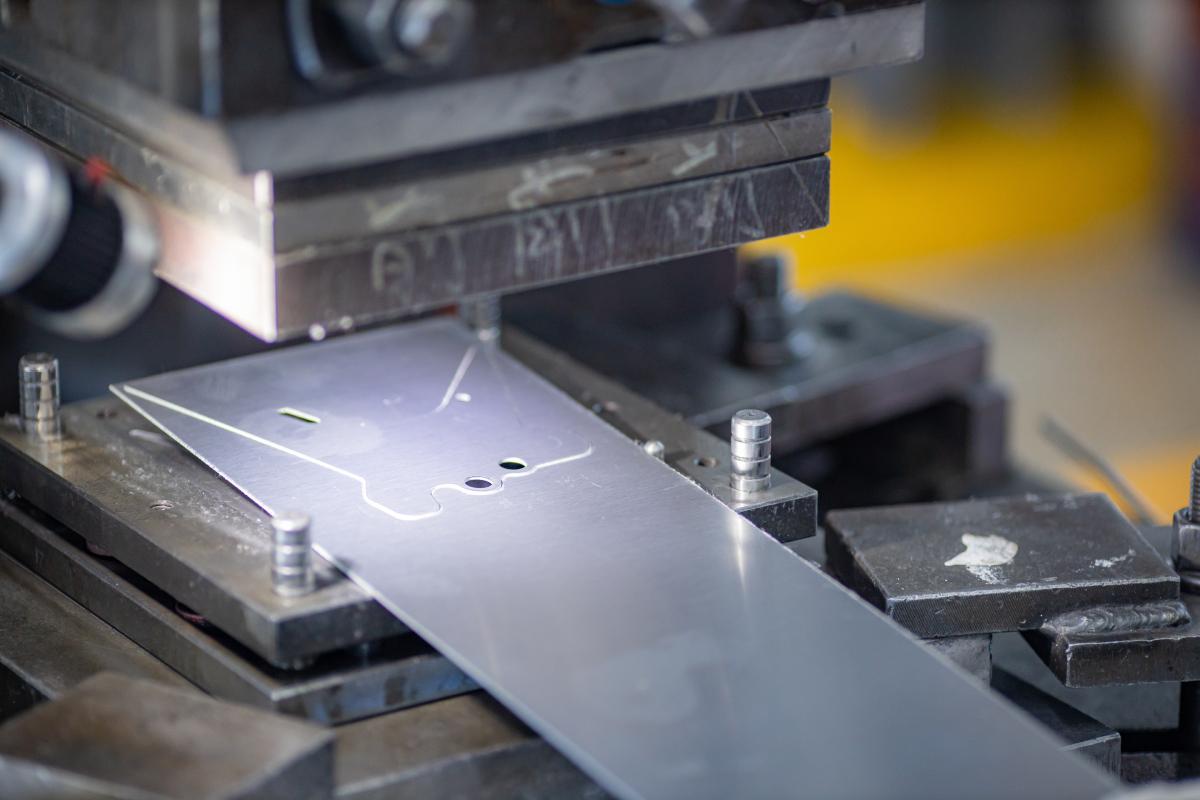

CNC machining

We provide CNC machining services of any complexity for the production of serial parts and prototypes. Get an instant quote!

Sheet metal processing

We provide stamping, bending, spinning. Stamping, cutting and welding standard-gauge metals for prototyping and low-volume production.

stamping

From welding and tapping processes to coating and assembly, we provide a range of value-added services to meet our customers' metal stamping project needs.

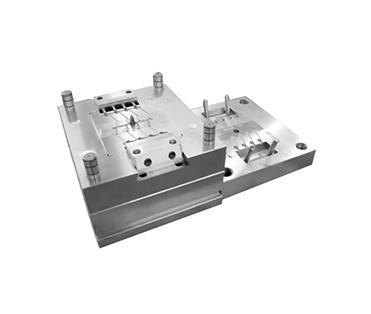

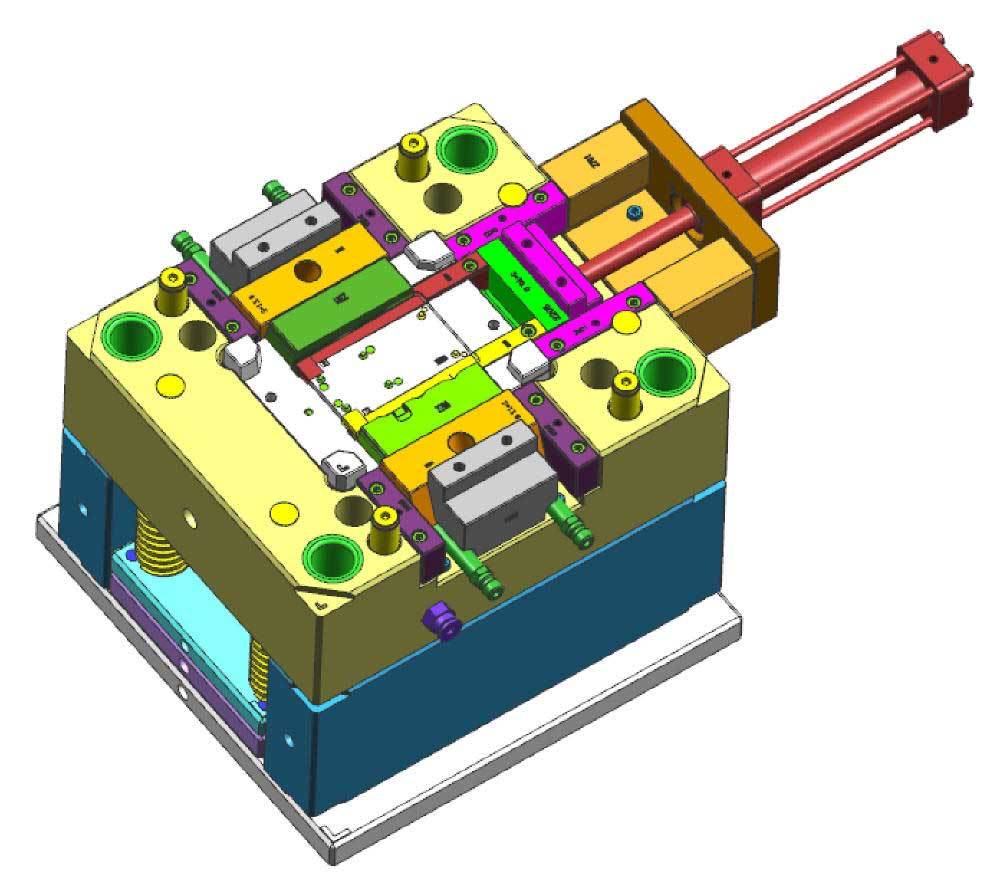

die casting

We provide a variety of high-quality metal die casting process services, including aluminum die casting, zinc die casting and magnesium die casting.

injection molding

Injection molding is widely used in mass production of various plastic products. This is the most economical way to manufacture large quantities of plastic parts.

surface treatment

We offer true production grade finishes such as painting, powder coating, anodizing and chroming for rapid prototyping and production.

what can we do:

1. Provide: focus on OEM & ODM;

2. Provide: provide free samples;

3. Provide: fast delivery;

4. Provide: strict quality control process;

5. Provide: ISO, IATF, SGS certification;

6. Provide: 24 hours online, professional and efficient communication;

7. Provide: experienced professional engineering team;

8. Provide: more than 29 years of professional one-stop CNC machining parts factory and manufacturer; focus on various CNC precision machining;

9. Provide: CNC machining parts, turning parts, milling parts, turning and milling combined parts, sheet metal parts, CNC brass parts, CNC aluminum parts, CNC steel parts, die casting parts, medical equipment parts, plastic parts, CNC turning parts , CNC processing parts, sheet metal parts, etc.

For free samples or for more details, please contact us! ! !

1. Provide: focus on OEM & ODM;

2. Provide: provide free samples;

3. Provide: fast delivery;

4. Provide: strict quality control process;

5. Provide: ISO, IATF, SGS certification;

6. Provide: 24 hours online, professional and efficient communication;

7. Provide: experienced professional engineering team;

8. Provide: more than 29 years of professional one-stop CNC machining parts factory and manufacturer; focus on various CNC precision machining;

9. Provide: CNC machining parts, turning parts, milling parts, turning and milling combined parts, sheet metal parts, CNC brass parts, CNC aluminum parts, CNC steel parts, die casting parts, medical equipment parts, plastic parts, CNC turning parts , CNC processing parts, sheet metal parts, etc.

For free samples or for more details, please contact us! ! !

To get the latest catalog or to send your custom requirements, please click to contact us! ! !

quality assurance

Want to know our overseas information? Please contact us! ! !

customer feedback

customer communication

VIEW MORE