API standard casing centralizer stop ring, oil well centralizer stop ring

- $10.00 / >=20 pieces

- 20 pieces

- Dongying Innova Petroleum Technology & Development Co., Ltd.

- Shandong, China

- Mr Yang Li

| Packaging Details: | Pallet or wooden box | Showroom location: | not any |

| Core component warranty: | 1 year | technology: | Casting, forging, machining or welding |

| Material: | Steel, Aluminum, Nylon, Polymer | payment terms: | L/C, Western Union, T/T, MoneyGram |

| Core components: | standard | After warranty service: | online support |

| brand: | Innova Petroleum Corporation | color: | red or request |

| application: | Oil and water well cementing tools | standard: | API Specification 10D |

| Outer diameter: | 4-1/2" - 20" | Applicable industries: | Energy and Mining |

| surface: | powder bake or paint bake | product name: | API casing centralizer stop ring, centralizer stop ring |

| Mechanical test report: | if | Local service location: | not any |

| Supply capacity: | 50000 pieces per month | port: | Tianjin, Qingdao, Shanghai or other Chinese ports |

| Warranty: | 2 years | Marketing Type: | normal product |

| Types of: | Bow Springs and Rigid Centralizers, Stop Rings Stop Rings | Video shipment inspection: | if |

| model: | standard |

API standard oil well casing centralizer limit ring

Types of | |

Product Details

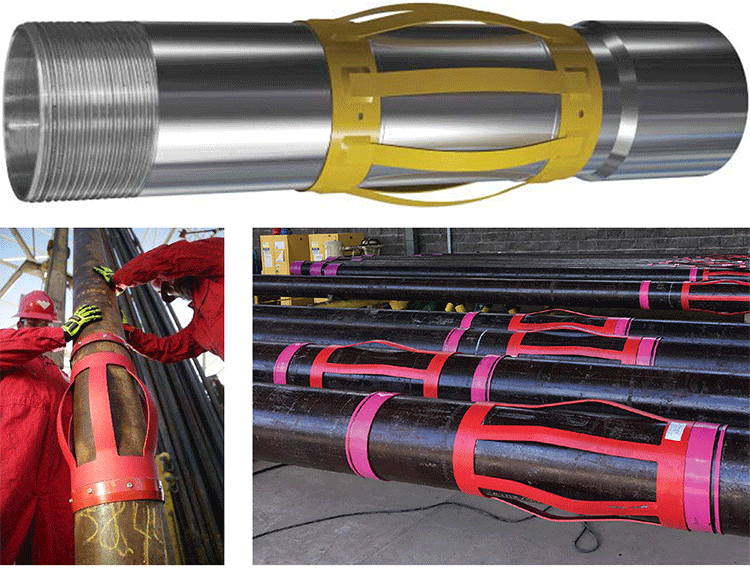

Casing centralizer is used as a cementing tool in vertical wells, deviated wells and horizontal wells to centralize casings and improve cementing quality. Cement can set between the casing and the well wall. It can be installed at the bushing joint or anywhere it is centered with the stop ring. Our centralizers are available in API standard sizes ranging from 4-1/2" to 20" and are powder baked or painted. The product has high tensile strength and yield strength, impact resistance, impact resistance and corrosion resistance.

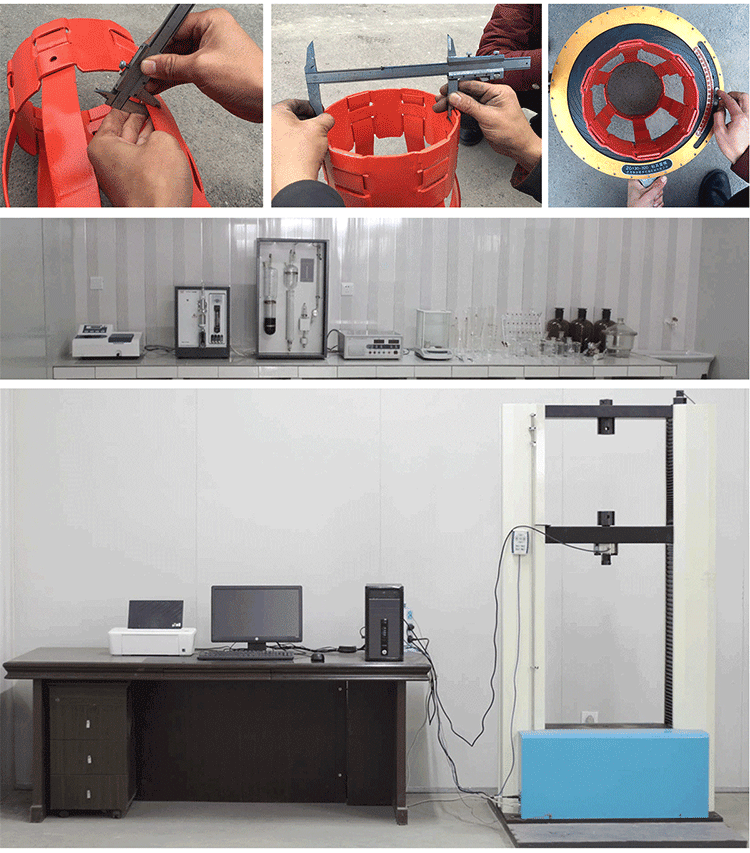

Testing and Inspection

Our company pays attention to product quality. Product quality is strictly controlled in accordance with API standards and customer special requirements.

** Raw materials: pass chemical and physical performance tests to ensure that the raw materials are qualified;

**Semi-finished products: According to the factory inspection plan, multi-dimensional inspections are carried out on the semi-finished products, such as the appearance, size and physical properties of centralizer flat steel. Only qualified products can enter the next step of production;

**Final product testing: All product details are tested and checked. In addition to the basic dimensions (vision, size, physical performance, etc.), the starting force, running force and recovery force are all tested by professional testing machines. Only qualified products will be marked and then shipped.

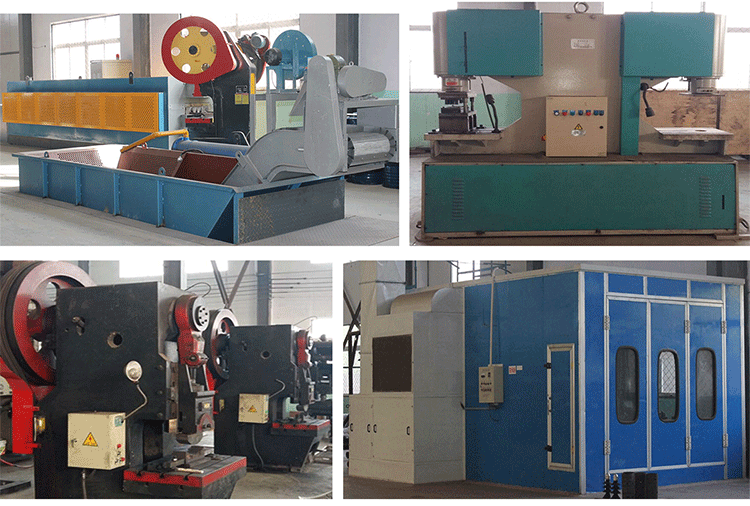

Packaging and Shipping

Our couplings are packed in pallets or wooden boxes. The professional box loading machine keeps the quality and appearance of the product from being damaged.