Automatic Cow Milking Machine China10 Locations

- $1000.00 /piece

- 1 piece

- FORSURE ADVANCED AUTOMATION LIMITED

- Guangdong, China

- Mr Dennis LAM

PRODUCT DETAIL

| pack: | wooden box | Applicable industries: | Mechanical Repair Shops, Farms, Retail Stores, Others |

| Core components: | Pump | Function: | milk sunscreen |

| State of health: | new | Supply capacity: | 100 boxes per week |

| Packaging Details: | Milk barrels are packed in standard cartons, and milk pasteurizers are packed in wooden boxes. Export wooden cases or pallets or cartons according to customer requirements | Showroom location: | not any |

| product name: | portable milking machine | Main selling points: | Free spare parts, on-site installation, commissioning and training, etc. |

| After warranty service: | Video Technical Support | Certification: | CE&ISO9001 |

| Pulse frequency: | 60:40 | Local service location: | not any |

| port: | Shenzhen | Keyword one: | Cow goat milking parlor equipment |

| Marketing Type: | New Products 2020 | Keyword two: | milking parlor milking machine milking parlor |

| brand: | JCom | place of origin; place of origin: | Guangdong, China |

| usage: | cow milking system | Mechanical test report: | if |

| use: | Milking cows and goats | Video shipment inspection: | if |

| Core component warranty: | 1 year | weight: | custom made |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Types of: | dairy shop |

| Voltage: | 380V | Dimensions (L*W*H): | custom made |

| Name: | Herringbone milking parlor cow milking machine | Warranty: | 1 year |

| feature: | High efficiency and simple operation | After-sales service provided: | Video technical support, online support |

| Material: | stainless steel 304 |

Portable Cow Milking Equipment Dairy Farm Milking Machine

Product Description

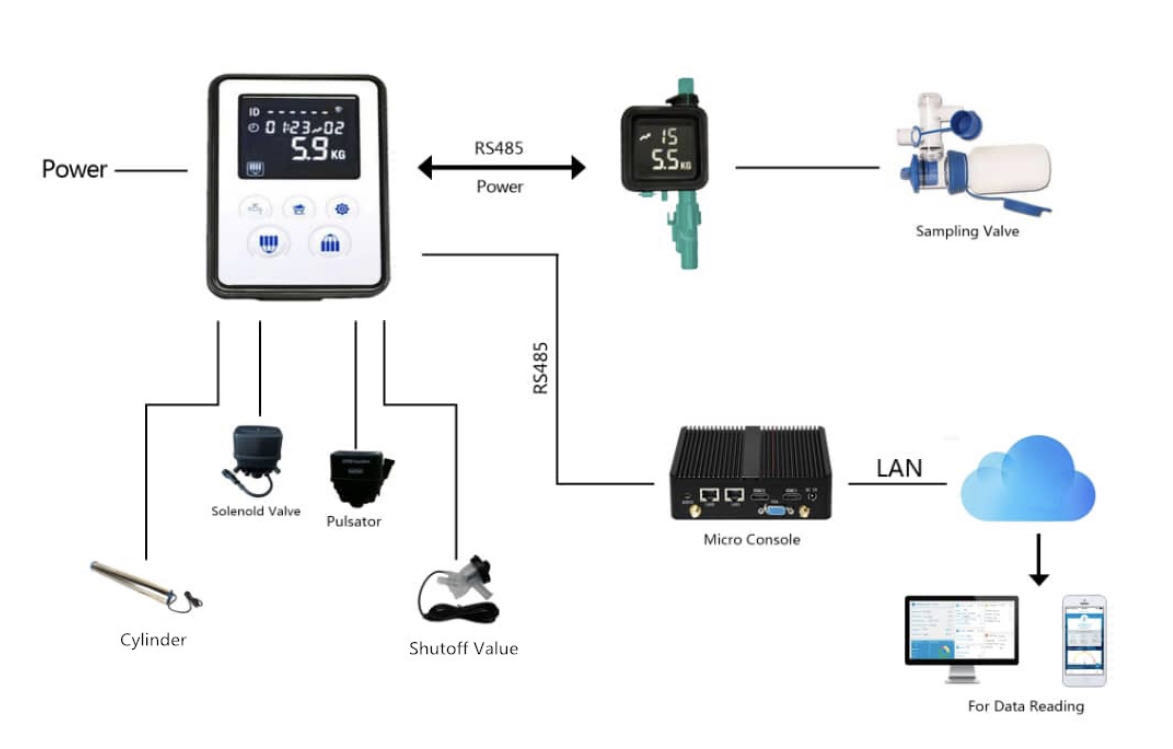

Product DescriptionThe milking parlor includes: vacuum system, milking system, glass bottle measurement system, milk collection system, residual milk recovery and cleaning device, cleaning system, electric control system, basic pipeline, scaffolding, etc.

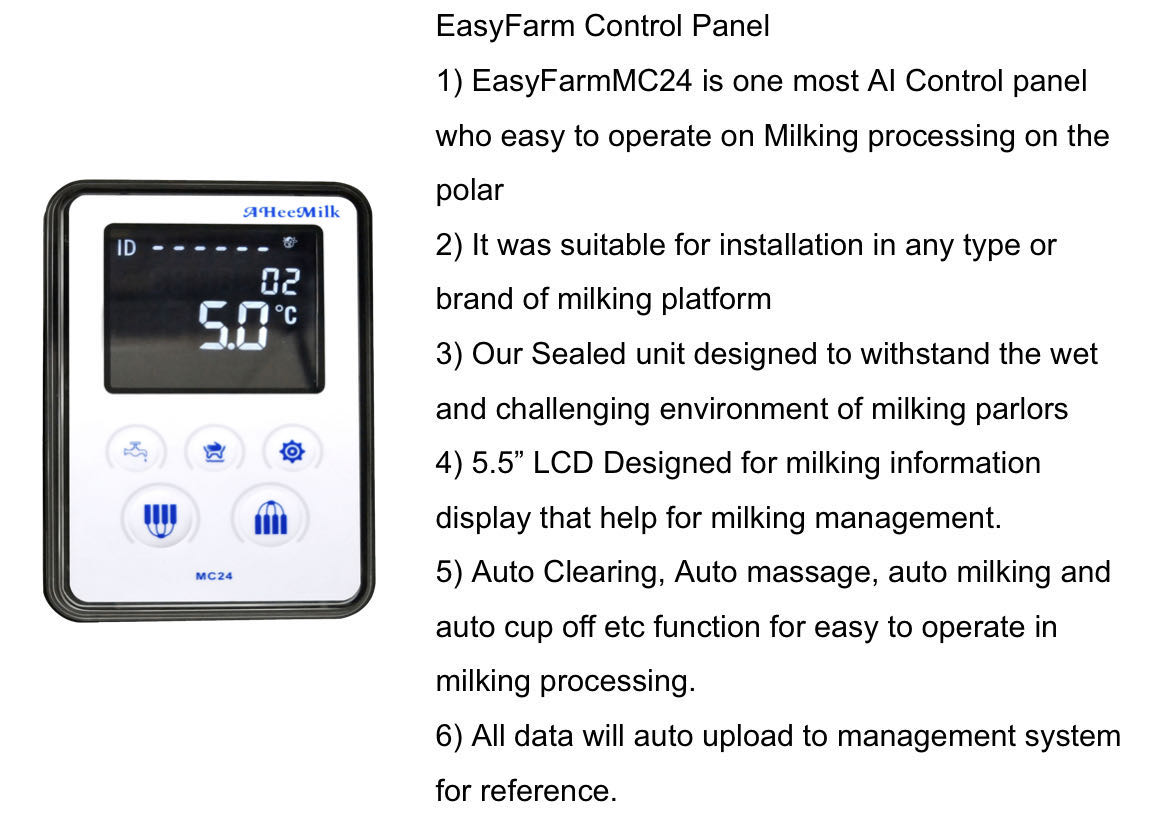

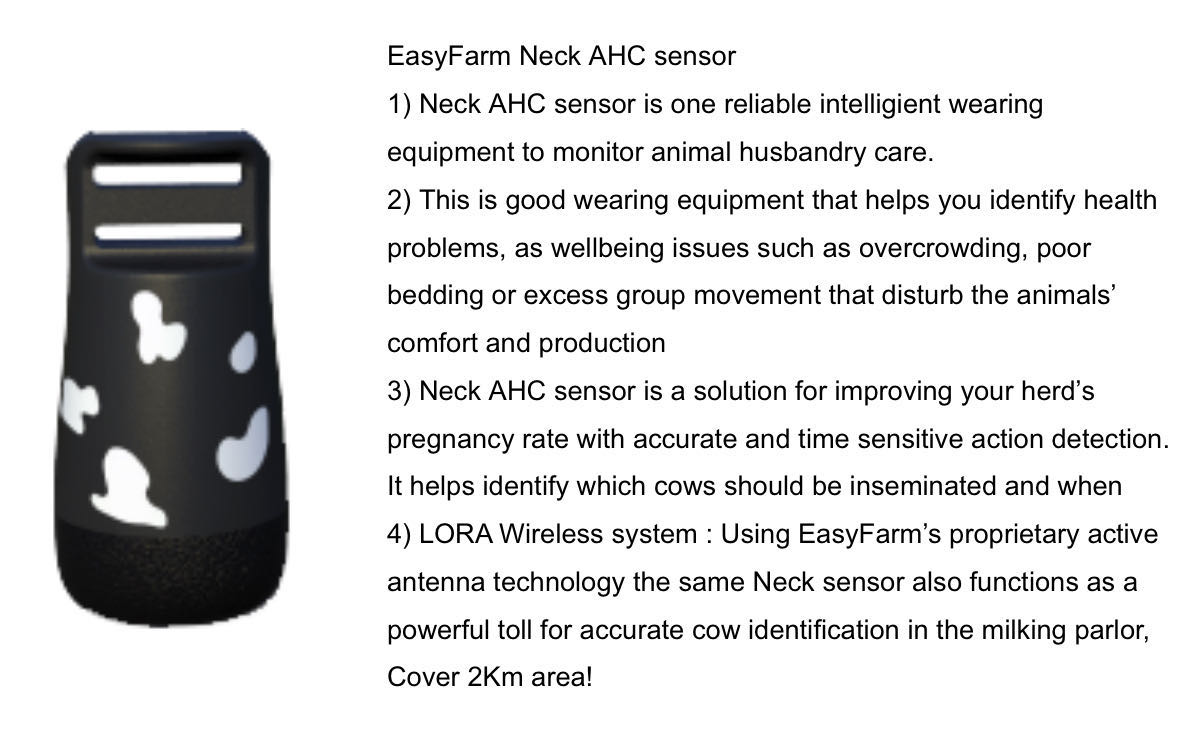

We have the following models of cow milking systems, which monitor the health status of cows (and their estrus period) and control the system through mobile phones and computers, making cow milking more artificial intelligence.

Using negative pressure and frequency conversion of the pulsator, the inner sleeve of the milk cup is alternately opened and closed for milking.

Some dairy farms have so many cows that manual milking takes a long time. Therefore, in order to improve milking efficiency, it is necessary to install a set of milking parlors. There are 2 parallel lines in the milking parlor, and each line can be installed with 4 gears, 6 gears, 8 gears,

ETC,. Milk 8 cows, 12 cows, 16 cows and more. once. You can express about 3-4 times an hour

Specification

Specification|

Model

|

Herringbone

|

||||||

|

|

9JY-2*8

|

9JY-2*12

|

9JY-2*16

|

9JY-2*20

|

|||

|

working vacuum

|

50Kpa

|

50Kpa

|

50Kpa

|

50Kpa

|

|||

|

Pulse ratio

|

60/40

|

60/40

|

60/40

|

60/40

|

|||

|

frequency

|

60 ± 3 rpm

|

60 ± 3 rpm

|

60 ± 3 rpm

|

60 ± 3 rpm

|

|||

|

Vacuum pump power

|

5.5 kW

|

2*4kw

|

2*4kw

|

2*5.5kw

|

|||

|

Vacuum pump speed

|

2300 l/min

|

2*1400L/min

|

2*1400L/min

|

2*2300L/min

|

|||

|

Milk pump speed

|

8 tons/hour

|

20 tons/hour

|

20 tons/hour

|

20 tons/hour

|

|||

|

milk pump power

|

2.2KW

|

4KW

|

4KW

|

4KW

|

|||

detailed drawing

detailed drawingparallel milking machine

★Standard size existence

2*4 and 2*6 and 2*8 and 2*10 and 2*12 and so on. Or it can be customized according to your requirements!

2*4 and 2*6 and 2*8 and 2*10 and 2*12 and so on. Or it can be customized according to your requirements!

★ It is one of the most widely used equipment in large farms. The automatic lifting scaffolding system shortens the milking work line and maximizes the milking efficiency. Due to the high density of oxtails, the construction area of the milking parlor is relatively reduced, which greatly saves the construction cost. According to user needs, the equipment can be equipped with the world's most advanced Afikim farm management software, becoming the most practical high-end equipment.

★Milking machine features

1. Residual milk recovery system: After milking, the remaining milk enters the collection tank through the sponge ball and butterfly valve to reduce bacteria, save labor, water and electricity, and increase income. This system is our unique advantage compared to other factories.

2. Semi-automatic cleaning system: After recovering the milk, manually add acid-base cleaning solution to clean the milking parlor (water flow).

1. Residual milk recovery system: After milking, the remaining milk enters the collection tank through the sponge ball and butterfly valve to reduce bacteria, save labor, water and electricity, and increase income. This system is our unique advantage compared to other factories.

2. Semi-automatic cleaning system: After recovering the milk, manually add acid-base cleaning solution to clean the milking parlor (water flow).

3. Ordinary dairy cow exit shed: All cows enter the shed from one exit, and after milking, all cows leave from the other exit one by one.

Applications

Applications1) The cow milking parlor is mainly used for sheep milking.

2) It is suitable for the milking parlor of large and medium-sized farms or milk collection stations, providing advanced milking equipment.

3) The milking parlor is used for various animals such as milking cows, goats, sheep and donkeys.

VIEW MORE

YOU MAY LIKE