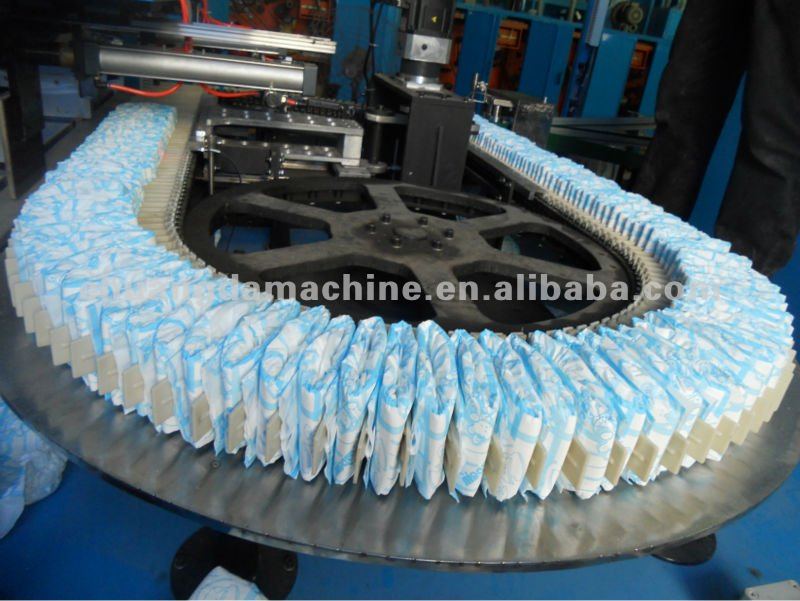

Baby diaper machine, baby diaper production line, baby diaper making machine

- $250000.00 / 1 - 1 sets

$220000.00 / >=2 sets - 1 set

- Quanzhou Chuangda Machinery Manufacture Co., Ltd.

- Fujian, China

- Ms Tina Ceng

| Certification: | ce | Production capacity: | 98% |

| Packaging Details: | Wooden packing | Processing type: | origami machine |

| Voltage: | 380 Volts 60 Hz | weight: | 40000 kg |

| port: | Xiamen | Mechanical test report: | if |

| Applicable industries: | manufacturing plant | Supply capacity: | 12 sets per year |

| Marketing Type: | New Products 2020 | Showroom location: | Egypt, Indonesia |

| Product Category: | Diaper machine | payment terms: | L/C, T/T |

| Baby diaper machine speed: | 300-350 tablets/min | Package preview: | |

| Video shipment inspection: | if | Core component warranty: | 1.5 years |

| brand: | Chuangda | Dimensions (L*W*H): | 25*3*2.5 |

| After-sales service provided: | Video Technical Support | Origin: | Fujian China |

| Warranty: | 1 year | strength: | 120 kW |

| Core components: | PLC, pressure vessel, motor, water pump | Health status: | new |

baby diaper machine

- The main technical parameters:

Design production speed: 300-400 pieces/minute

Stable production speed: 350 pieces/min

Machine power supply: 380V 50Hz

Overall machine capacity: 130KW (including glue machine power)

Scrap rate ≤ 2% (excluding hot melt machine failure or refueling)

Product specifications: S, M, L, XL

Dimensions (excluding crusher): 19m*1.6m.3.1m(L*W*H)

Equipment weight: 25 tons

- basic assembly unit

--This machine is controlled by touch screen PLC, which automatically removes waste materials

--The hammer crusher can take raw pulp, semi-concrete pulp and treated pulp, and the remote button can adjust the supply of wood pulp.

--The frame is made of reasonable and high-quality square steel.

--The cotton core is formed in a single-pass screen wheel, and the cotton core is composed of two sheets of thin paper with a layer of wood pulp in between.

--SAP is mixed with wood pulp, and the spraying amount of SAP can be adjusted by remote buttons.

-- Embossing is carried out on the cotton core, the embossing pattern is generally net square, and the embossing shape can be made according to customer requirements.

-- Lining with diversion NW fabric unit.

--Cotton core is cut by cutter.

--With leakage protection device, hot pressing type.

--With elastic waist device.

--Belt left and waist belt adding belt device, the gap can be adjusted to adapt to the production of different widths such as L, M, and S.

--With front tape unit.

--The machine is equipped with an elastic rubber band unwinding device, in which there are multiple elastic bands on both sides of the cotton core, and two elastic bands on both sides of the protective drain.

--The product comes with a curved cutter.

--The product is vertically clamped, cut and formed after compression.

--Three or two folds horizontally.

--Product alignment output.

--The air duct is PV

--The core is cut and driven by a universal joint.

--NW fabric cut.

- Rubber supply.

--NW fabric hem.

-- Diversion layer polyethylene funeral transfer.

--Three-piece pressure combination.

--Protection leakage

--Sorted collection of waste bins.

--exercise system

--stop the installation.

--Motor system: main shaft, cardan shaft transmission, gearbox, timing belt, the transmission mode is coupling + closed gearbox + timing belt.

--The main transmission shaft adopts universal joint coupling.

--Main drive shaft diameter 45.

--Other configuration features: glue spraying part with indicator light, transmission belt maintenance.

--With a counter.

3. Main component suppliers:

--The main resistance sensor adopts Mitsubishi, Japan

--The frequency converter is controlled by Mitsubishi.

--Cullery, American D2 raw material.

---Japan Mitsubishi brand PLC

----Japan Mitsubishi brand servo motor

4. Spare parts:

--3 sets of glue applicators

-- 2 sets of flat knives

--Other fragile parts.

- Operation Manual