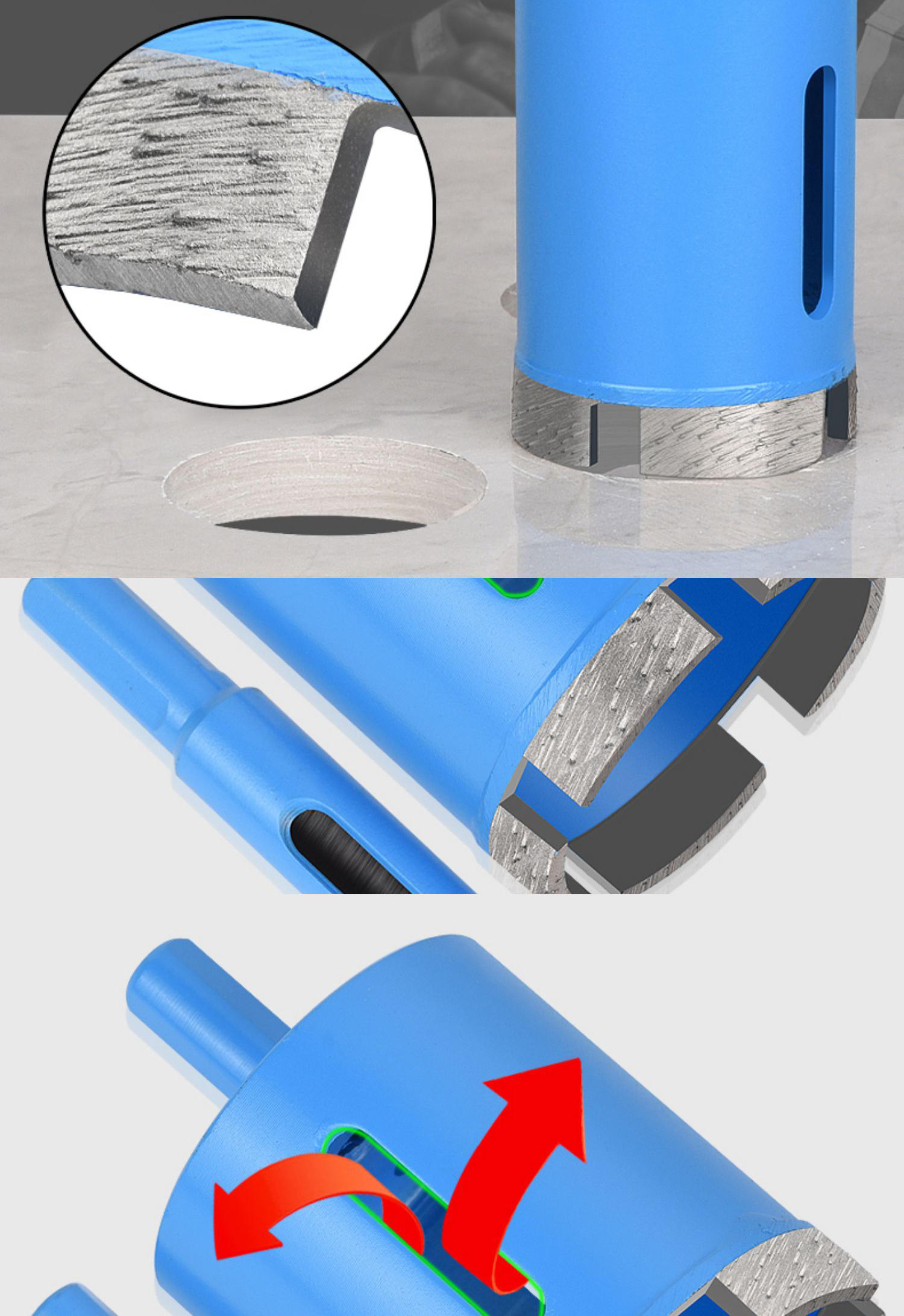

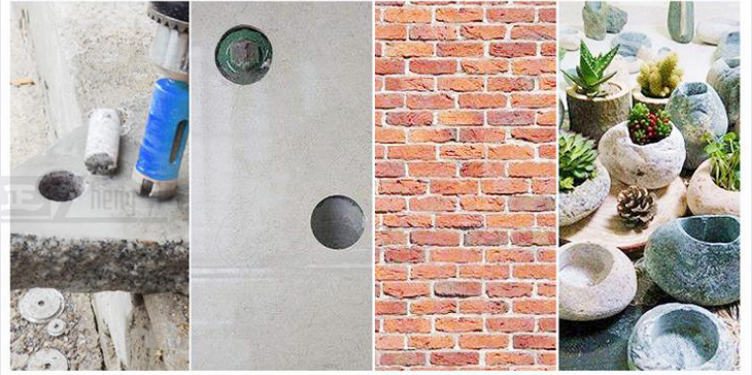

Best Performance Diamond Segmented Coring Bits for Granite Marble Tile Glass

- $3.83 / 10 - 199 pieces

$2.62 / 200 - 1999 pieces

$2.22 / >=2000 pieces - 10 pieces

- Apex Diamond Tools Co., Ltd.

- Fujian, China

- Mr jack wong

PRODUCT DETAIL

| product name: | diamond bit | Applies to: | Stone, Granite Marble Tile Glass |

| port: | Xiamen, China (Available in Shenzhen, Shanghai and Ningbo) | Surface treatment: | painting, plain |

| application: | drilling | color: | blue |

| Number of segments: | 3 | Customization support: | OEM production |

| diameter: | 10mm-45mm | Handle: | Straight handle |

| point angle: | * | Advantage: | high efficiency |

| Packaging Details: | Standard export carton | Supply capacity: | 10000 pieces per day |

| Material: | diamond | Package preview: | |

| payment terms: | L/C, Western Union, T/T, MoneyGram |

Product Description

Specification

MOQ | 10pcs | ||||||

OEM/Design and Manufacturing | OEM/ODM and other working thicknesses and designs are available. | ||||||

main market | Sold to the domestic market (30.00%), North America (20.00%), Southeast Asia (10.00%), Eastern Europe (10.00%), Middle East (10.00%), South America (5.00%), Africa (5.00%), Western Europe (5.00%), East Asia (5.00%). | ||||||

delivery time | Generally 3-7 days in stock, 7-20 days out of stock. It is limited in quantity. | ||||||

pricing term | EXW, FOB, CFR, CIF, CIP, CPT, door to door express | ||||||

payment terms | Payment <= 1000 USD, 100% in advance. Payment >= USD 1000, 30% deposit, balance before shipment. | ||||||

feature:

Wet pads need to be continuously cooled with water during the grinding process. No dust, higher gloss, less damage to stone.

Dry pads are designed for jobs that don't use water and can withstand high temperatures. But wetting the surface of the object with a small amount of water for polishing will eventually achieve better results.

Polish system:

For polishing stones, a sequence from coarse to fine is used, finally polishing at high speed and flawless performance.

Step 1: Coarse grinding 50#/150# or 50#/100#, sharp and durable, smooth stone.

The second step: fine grinding 300#/500# or 200#/400#, polishing scratches.

The third step: fine grinding 1000#/2000#/3000# or 800#/1500#/3000#, the polishing degree is about 80 degrees.

Step 4: polishing 0#(buff) Add 1 BUFF to get about 90-100 polishing pads.

Wet pads need to be continuously cooled with water during the grinding process. No dust, higher gloss, less damage to stone.

Dry pads are designed for jobs that don't use water and can withstand high temperatures. But wetting the surface of the object with a small amount of water for polishing will eventually achieve better results.

Polish system:

For polishing stones, a sequence from coarse to fine is used, finally polishing at high speed and flawless performance.

Step 1: Coarse grinding 50#/150# or 50#/100#, sharp and durable, smooth stone.

The second step: fine grinding 300#/500# or 200#/400#, polishing scratches.

The third step: fine grinding 1000#/2000#/3000# or 800#/1500#/3000#, the polishing degree is about 80 degrees.

Step 4: polishing 0#(buff) Add 1 BUFF to get about 90-100 polishing pads.

skills:

1. Put on the apron, mask and protective glasses first.

2. Attach the back-up pad to the polisher or angle grinder and attach the 50-grit polishing pad to the back-up pad.

3. Set the speed at 3,000-4,000RPM and start the polishing process.

4. Going up and down twice and up and down once is a good technique. Make sure to remove all previous scratches before moving on to the next grit.

5. Repeat the same process with all 7 pads to complete the polishing process. Polishing from 50 grit to 3000 grit respectively. Don't skip.

6. If you want the best polish on granite or other natural stone, use a polishing pad as the final step.

Wet the workpiece and run the polishing pad semi-wet with very low water. The process is complete when the water is consumed. Repeat as needed to improve shine and achieve mirror effect results.

1. Put on the apron, mask and protective glasses first.

2. Attach the back-up pad to the polisher or angle grinder and attach the 50-grit polishing pad to the back-up pad.

3. Set the speed at 3,000-4,000RPM and start the polishing process.

4. Going up and down twice and up and down once is a good technique. Make sure to remove all previous scratches before moving on to the next grit.

5. Repeat the same process with all 7 pads to complete the polishing process. Polishing from 50 grit to 3000 grit respectively. Don't skip.

6. If you want the best polish on granite or other natural stone, use a polishing pad as the final step.

Wet the workpiece and run the polishing pad semi-wet with very low water. The process is complete when the water is consumed. Repeat as needed to improve shine and achieve mirror effect results.

VIEW MORE

YOU MAY LIKE