Chemical composition of ground granulated blast furnace slag

- $50.00 / 5000 - 9999 pieces

$45.00 / >=10000 pieces - 5000 pieces

- Quanzhou Winitoor Import & Export Co., Ltd.

- Fujian, China

- Ms Winnie Chen

| GGBFS colors: | white/off-white | Types of: | slag |

| Fineness-Blaine(m2/kg): | greater than or equal to 400 | Alkalinity (%): | 0.06% |

| GGBFS H2O: | 1% max | GGBFS SO3(%): | 4% max |

| payment terms: | L/C, D/P, T/T, Western Union | Current ratio: | 95%min |

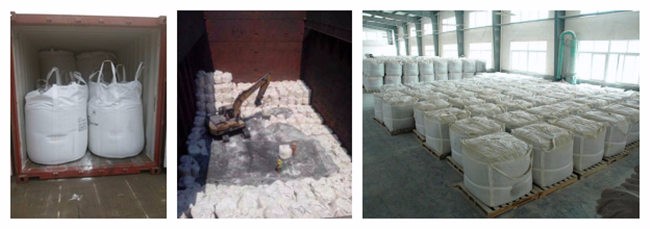

| Chloride(%): | 0.06%max | Packaging Details: | 1) GGBFS 1400kgs per jumbo bags 2) GGBFS can provide other packing upon request |

| model: | S95 | brand: | Wittur |

| GGBFS Density (g/cm3): | greater than or equal to 2.80 | port: | Caofeidian |

| Vitreous body (%): | 85%min | GGBFS Letter of Intent: | 3% max |

| Shipping Details: | Within 15~30 days | Supply capacity: | 100,000 tons per month |

| place of origin; place of origin: | Fujian China |

Product Description:

WNT-GGBFS is ground blast furnace slag powder, if used in concrete; it reacts with Ca(OH)2 to form additional binder CSH, which significantly reduces its permeability. Reduced permeability resists chloride attack and carbonation injection.

Adding WNT-GGBFS to concrete will improve most of its properties such as impermeability, compressive strength, etc. , the most important is its durability.

Features Features:

- Enhances the durability of concrete and reduces maintenance and repair costs.

- Reduce cement and water consumption

- Improved workability and compaction characteristics

- Increased compressive and flexural strength

- Improve concrete grading.

- Improve impermeability and water resistance.

Application fields:

- water structure engineering

- High-rise building pouring

- Concrete Pipe Industry

- Deep and submerged foundation.

- Concrete in aggressive chemical attack

- in coastal or hot climates

- Low water cement ratio concrete mixture.

an examination:

Technical Information

Check item | grade | |||

S105 | S95 | S75 | ||

Density: g/cm3not less than | 2.80 | |||

Specific surface area: m2/Kilogramnot less than | 500 | 400 | 300 | |

Activity index: % not less than | 7 days | 95 | 75 | 55 |

28 days | 105 | 95 | 75 | |

Liquidity ratio: % not less than | 95 | |||

Moisture content: % not less than | 1.0 | |||

sulphur trioxide:%not less than | 4.0 | |||

Chloride ion: % not less than | 0.06 | |||

Loss on ignition: % not less than | 3.0 | |||

Note: Higher grade slag powder can be produced according to customer requirements | ||||

China High Density Micro Silica Fume/Silica Fume For Concrete/Cement Best Micro Silica Fume/Silica Fume For Concrete Blocks

company information:

WINITOOR was established in 2004 in Quanzhou City, Fujian Province, China. We specialize in the R&D, production and sales of a series of building materials: microsilica fume (microsilica fume), GGBFS, water reducers...their application in concrete (HPC), mortar, refractory materials, etc. We have established our own silicon micropowder processing plants in the main areas of China's ferrosilicon and metal silicon factories, with an annual output of more than 50,000 metric tons.

With years of good reputation and good service in the international market, WINITOOR has established good business relationships with customers from all over the world, including Middle East countries, Japan, Korea, Vietnam, Indonesia, Europe, North America, Southeast Asia, Latin America, Africa etc.

Packaging and Shipping:

our service:

Reply to your inquiry within 24 working hours.

2. Experienced staff answer all your questions in professional and fluent English.

3. Special discounts and protections for your dealership's sales area.

4. The packaging granularity of the content can be customized according to customer needs.

5. Our goal is to make the best alloy in China.

contact us:

Tel: +86-595-22288318 Fax: +86-595-22288319

Mobile: 0086 18650069942 (24 hours online)

Email: sales8 at winitoor.com

Our company promises: reasonable price, efficient production time, satisfactory after-sales service.