Chromite SandChromite Powder-200mesh-400mesh-325mesh

- $280.00 /piece

- 1 piece

- Henan Sicheng Abrasives Tech Co., Ltd.

- Henan, China

- Mr Henry Hu

| Cr2O3 (minimum): | 46% | brand: | Sicheng Abrasives |

| Silica %: | 1.0% max | Packaging Details: | 1000 kg in a sturdy big bag |

| size: | 325#,200#,100#AFS35-40 AFS40-45 AFS45-50 | model: | AFS35-40 AFS40-45 AFS45-50 AFS50-55 AFS55-60 AFS60-65, all sizes available |

| Packaging Preview: | Bulk density: | 2.5-3.0g/cm3 | |

| Supply capacity: | 2000 metric tons per month | chemical composition: | Cr2O3 46% minimum |

| Keyword 2: | Chromite powder | usage: | Refractory, foundry, ladle filler sand, glass, ceramics |

| Keyword 3: | Chromite powder - 200 mesh | Keyword 1: | chromite sand |

| Moisture (%): | 0.1% max | Concentrated or not: | is concentrated |

| place of origin; place of origin: | South Africa, South Africa | port: | Lianyungang |

| type: | piece | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Cr2O3%: | Minimum 46% | PH value: | 7-9 |

Chromite SandChromite Powder-200mesh-400mesh-325mesh

Foundry chromite sand is the natural processing product of chromite ore classified by crushing screen. The main chemical composition of chrome ore is cr2o3. This kind of sand has stable heating volume and high thermal conductivity. When it is in contact with molten metal, it not only has good alkali resistance , does not react chemically with ferric oxide, etc., and has the characteristics of solid phase sintering, which can well prevent the infiltration of molten metal and avoid sand hitting defects. It is suitable for all kinds of stainless steel, alloy steel and carbon steel to gradually form original Sand core and coating.

1. Technical services:

The technical team with more than 20 years of casting experience can provide better technical services.

2. Guaranteed delivery time:

Global logistics network, China loading port warehouse, guaranteed delivery time.

3. Chrome ore raw materials:

Chrome ore raw material comes from the best chrome ore - no more "surplus".

4. Customizable size:

AFS (about 25-70), the particle size distribution of sand can be customized according to customer requirements.

5. Cleanliness:

Turbidity is less than 100ppm (sand is clean), no low melting point substances. We frequently upgrade and replace sand cleaning equipment to ensure the cleanliness of our chrome sand.

Click here to contact us.

|

Chemical |

index |

physics |

index |

|

Cr2O3 |

≥46.0% |

Bulk density |

2.5-3g/cm³ |

|

silica |

≤1.0% |

pH value |

7-9 |

|

Fe2O3 |

≤26.5% |

Chromium/Iron |

1.55:1 |

|

Calcium Oxide |

≤0.30% |

packing density |

2.6 g/cc |

|

Magnesium oxide |

≤10% |

Moisture percentage |

≤0.1 |

|

AI2O3 |

≤15.5% |

Sintered |

1600°C |

|

phosphorus |

≤0.003% |

Sintering temperature |

2180°C |

|

C |

≤0.003% |

melting point |

>1800°C |

|

Regular size |

|||

|

AFS 25-35 AFS25-30 AFS30-35 AFS35-40 AFS40-45 AFS45-50 AFS50-55 AFS55-60 AFS60-65 |

|||

Chromite sand for the foundry industry

Its properties allow the material to be used as core and moulding sand in heavy duty grey cast iron and steel foundries. Its high thermal conductivity gives it good cooling properties, and its low thermal expansion gives it good dimensional stability. It has a near-neutral alkalinity and can be used with a variety of resin-bonding systems and inorganic binders, it has high refractoriness and a broad sieve distribution.

Chromite Sand in the Iron and Steel Industry

In steel production, chromite sand is used as a filler to protect sliding gates in large ladles.

Chromite Sand in the Glass Industry

When ground to a fine powder, chromite sand is used to produce green glass beverage containers.

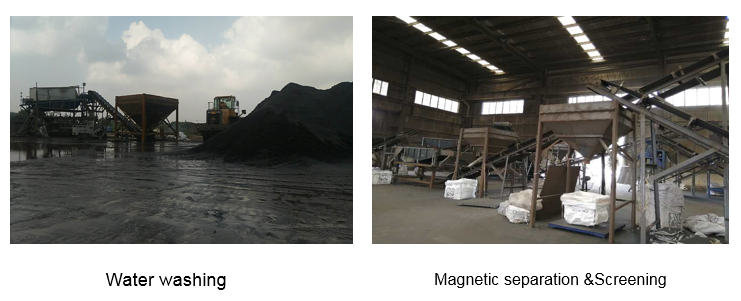

Step1: The chrome ore raw material is washed with water.

Step2, drying raw materials to remove moisture;

Step3. The dried raw materials enter the vibrating screen to screen out the size required by the customer;

Step 4. The size of the sieve is magnetically separated to achieve the purpose of removing iron and silicon. After magnetic separation, the chromium content reaches more than 46%, and the silicon content is less than 1%.

Step5: Packaging the finished product.

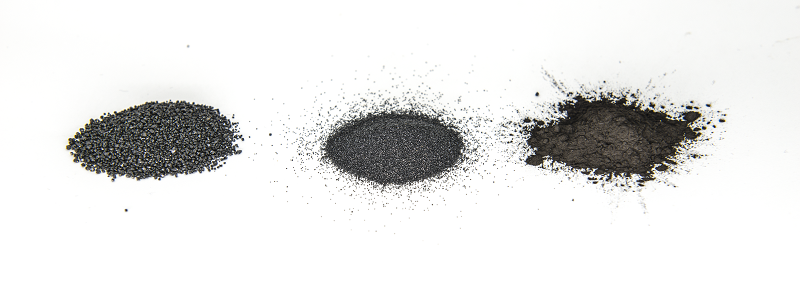

200# 325# 400# Fine Chromite 200# 325# 400# Fine Chromite 200# 325# 400# Fine Chromite

e

Other Products

-

Chromium Concentrate Production 46% Chromite Sand Price$320.00 - $330.00 / metric ton

Chromium Concentrate Production 46% Chromite Sand Price$320.00 - $330.00 / metric ton -

46% Cr2O3 foundry sand chromite AFS45-50$470.00 - $480.00 / metric ton

46% Cr2O3 foundry sand chromite AFS45-50$470.00 - $480.00 / metric ton