Competitive Price Save Labor Cost Automatic Feeding Trigger Spray Bottle Capping Machine

- $15714.99 / 1 - 4 sets

$12617.99 / 5 - 9 sets

$9861.99 / 10 - 29 sets

$4761.99 / >=30 sets - 1 set

- Guangzhou Zhen Xiang Smart Equipment Co., Ltd.

- Guangdong, China

- Ms Linda Liu

PRODUCT DETAIL

| Dimension(L*W*H): | 2400(L)*2650(W)*2480(H)mm; | Capping way: | Servo drive screw capping; |

| Product name: | Automatic Trigger Spray Bottle Capping Machine; | Video outgoing-inspection: | Provided; |

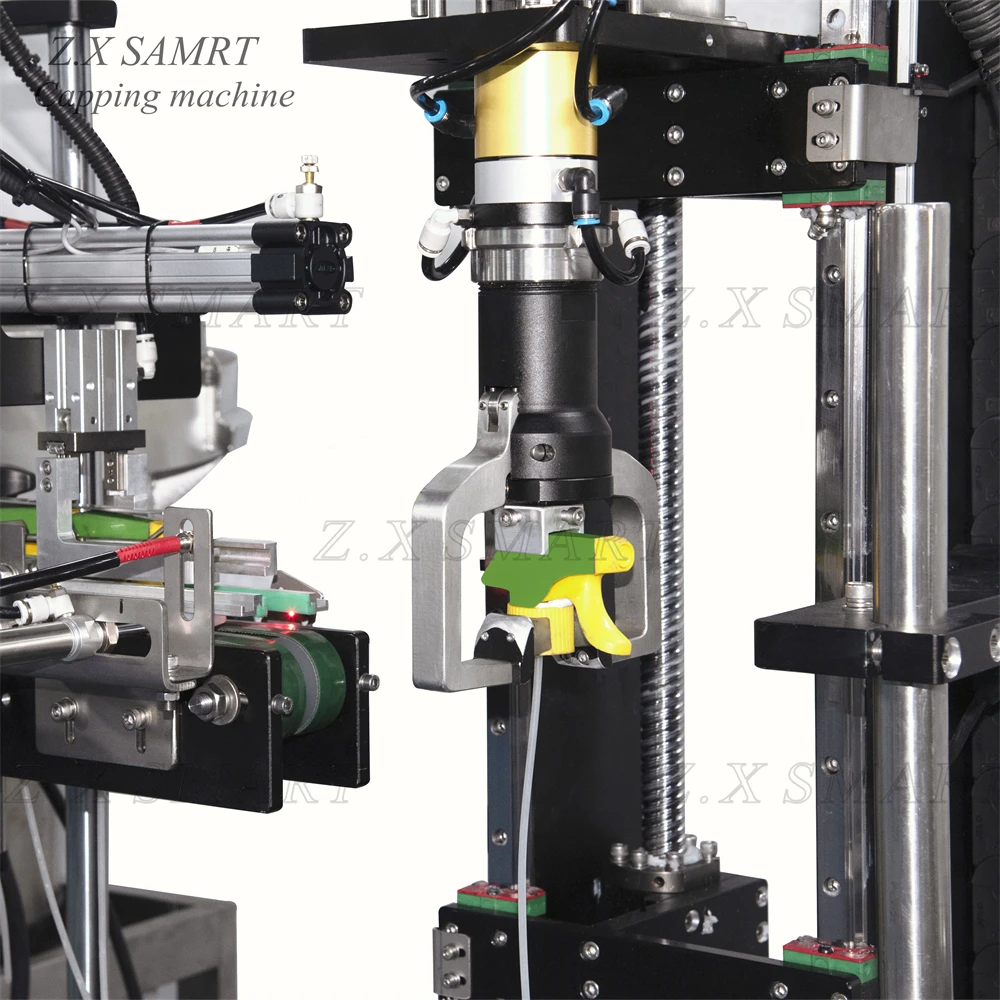

| Key Selling Points: | Automatic; | Cap feeding way: | Pneumatic fetch; |

| Control: | PLC+ Touch Screen; | Packaging Material: | Plastic,Metal,Glass; |

| Weight: | 450 KG; | Showroom Location: | Egypt,Philippines; |

| Application: | Food,Beverage,Commodity,Medical,Chemical; | Warranty: | 1 Year; |

| Suitable bottles: | Plastic spray trigger bottles; | Automatic Grade: | Automatic; |

| Voltage: | 220V-240V; | Core Components: | standard; |

| Marketing Type: | Ordinary Product; | Program control: | Share with filling machine; |

| Machine material: | Stainless steel 304; | Condition: | New; |

| Machinery Test Report: | Provided; | Packaging Detail: | 1. Each machine is packed in a wooden box; 2. Each part is wrapped in protection film.; |

| Capping distributor way: | Vibration shaking plate; | Port: | Guangzhou or other cities; |

| Payment Terms: | L/C,Western Union,T/T,MoneyGram; | Driven Type: | Electric; |

| Capacity: | 25-35 BPM; | Type: | Capping Machine; |

| Warranty of core components: | 1 Year; | Supply Ability: | 100 Sets per Month; |

| Conveyor belt: | 82mm wide, 800mm ground clearance; | Place of Origin: | Guangdong, China; |

| Brand Name: | ZX Smart; | Applicable Industries: | Food & Beverage Factory,Retail,Other,Factory; |

| Packaging Type: | Bottles; |

Competitive Price Save Labour Cost Automatic Feeding Trigger Spray Bottle Capping Machine

Product Description

Description:

This machine is used for automatic capping for plastic bottles and glass bottles in cosmetic, food, beverage, chemical industry and medicine industry. It can be applied to a variety of bottle types with high production efficiency.

Technical Parameter | ||

Apply the bottle cap | According to samples provided by customer | |

Bottle feeding method | Put the bottle manually | |

Cap sorter method | Vibration plate cover, elevator cap sorter replenishment | |

Cap putting form | Automatic pneumatic cap | |

Capping form | Servo grip | |

Capping speed | 20-30 bottles/min | |

Voltage | 2KW, AC220V, 50/60Hz, single phase | |

The material of frame is stainless steel | 0.6-0.8MPa | |

Dimension | 2500×800×1950mm(L×W×H) | |

Program control | PLC+Touch screen | |

Machine weight | About 400KG | |

Click Here For More Information | ||

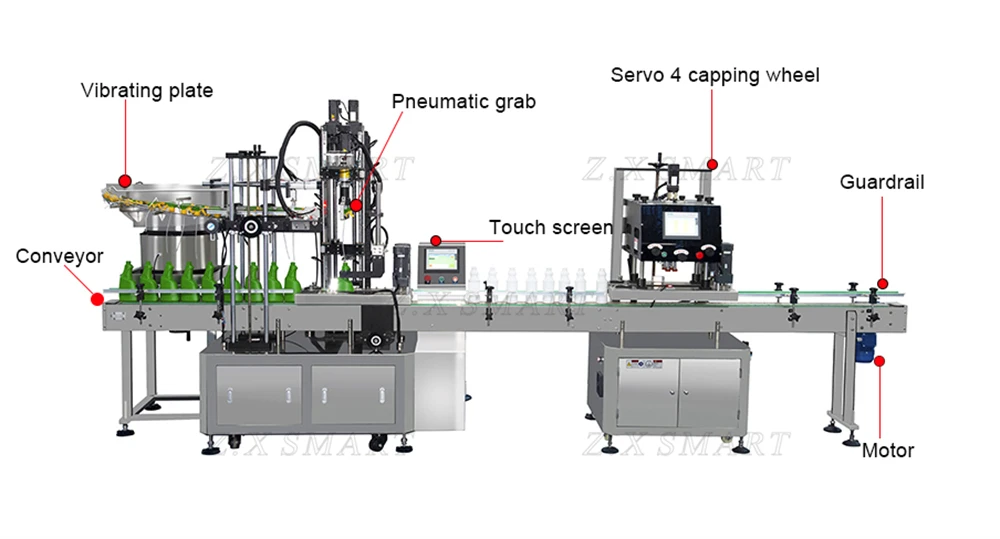

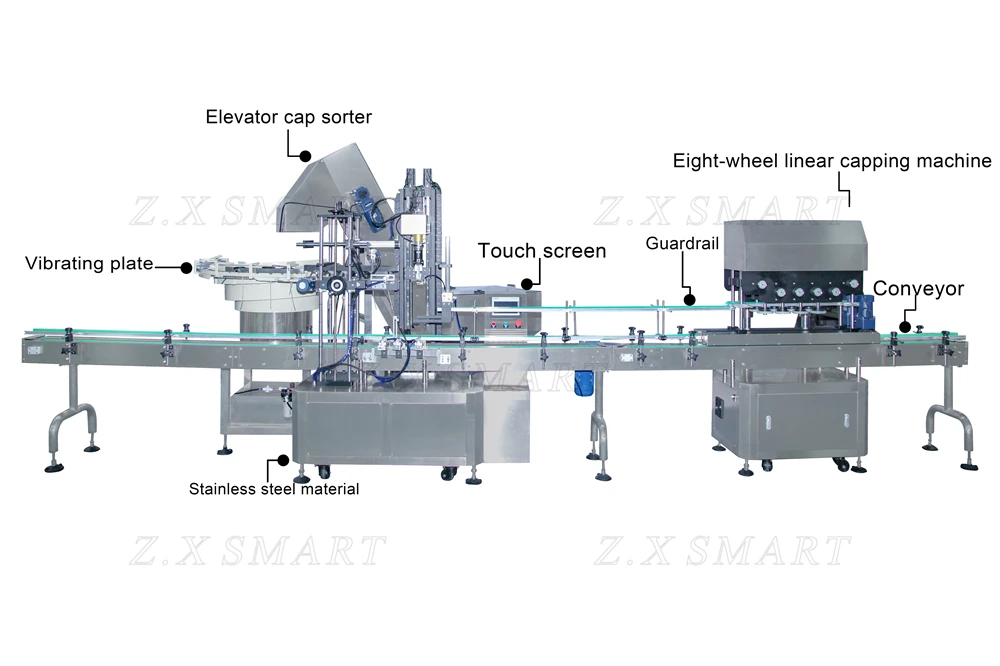

Different modes for choosing ↓

Mode One

Mode Two

Linear Capping Machine

Servo Capping Machine

Please send us message if you need more information ☺

This is a fully automatic production line, which is simple to assemble without too much adjustment. It can help you improve work efficiency and save a lot of production costs.

Different Filling Capping machine for choosing

Related Products

Company Profile

Packing & Delivery

Our Service

FAQ

Q:What industry is your product suitable for?

A:The product line we develop and produce is suitable for the production of various, liquid, paste, powder, solid products. The specific product materials, functions, specifications and production capacity can be customized according to customers' products and requirements.

Q: What if the machine fails during use?

A:Our products will be carefully inspected and ensured before delivery, and we will provide the correct instructions for use of the products; in addition, our products support lifetime warranty warranty service, if there are any questions during the use of the product, please consult our work. personnel.

Q: When can I get my machine after paid?

A: The delivery time of a production line is generally 60 days; the product is about 15-30 days.We will deliver it on time as the date we agreed both side.

Q: How can I install my machine when it arrives?

A: We will provide installation videos and tutorials, or send our engineer to your side ASAP you get all your machines ready , for testing and teaching your technicians how to run the machines.

Q:What payment do you accept?

A: We generally use T/T or L/C, and we can negotiate the payment method.

A:The product line we develop and produce is suitable for the production of various, liquid, paste, powder, solid products. The specific product materials, functions, specifications and production capacity can be customized according to customers' products and requirements.

Q: What if the machine fails during use?

A:Our products will be carefully inspected and ensured before delivery, and we will provide the correct instructions for use of the products; in addition, our products support lifetime warranty warranty service, if there are any questions during the use of the product, please consult our work. personnel.

Q: When can I get my machine after paid?

A: The delivery time of a production line is generally 60 days; the product is about 15-30 days.We will deliver it on time as the date we agreed both side.

Q: How can I install my machine when it arrives?

A: We will provide installation videos and tutorials, or send our engineer to your side ASAP you get all your machines ready , for testing and teaching your technicians how to run the machines.

Q:What payment do you accept?

A: We generally use T/T or L/C, and we can negotiate the payment method.

VIEW MORE

YOU MAY LIKE