Complete water bottle production line / water filling machine / mineral water plant project

- $2000.00 /set

- 1 set

- Zhangjiagang Lucky Machinery Co., Ltd.

- Jiangsu, China

- Ms josie wu

PRODUCT DETAIL

| Weight: | 8000 KG; | Filling speed: | 1000-36000bph; |

| keyword: | mineral water plant project; | PLC: | Siemens; |

| Package Preview: | ; | Brand Name: | Lucky; |

| Warranty: | 2 years,2 Years; | Supply Ability: | 5 Sets per Month mineral water plant project; |

| Voltage: | Customized,Customized; | Core Components: | PLC; |

| Dimension(L*W*H): | 4000*3000*3100; | Automatic Grade: | Automatic; |

| Key Selling Points: | Easy to Operate; | Packaging Material: | Plastic,Glass,PET; |

| Place of Origin: | Jiangsu, China; | Driven Type: | Electric; |

| Port: | shanghai; | Showroom Location: | Thailand,Malaysia,None; |

| Warranty of core components: | 2 years; | Video outgoing-inspection: | Provided; |

| After Warranty Service: | Video technical support,Online support,Spare parts; | Local Service Location: | Thailand,Malaysia; |

| Marketing Type: | Hot Product 2019; | Applicable Industries: | Manufacturing Plant,Food & Beverage Factory; |

| Condition: | New; | Machinery Capacity: | 4000BPH,8000BPH,12000BPH; |

| Filling Material: | Mineral/Drinking water/pure water; | Type: | Filling Machine; |

| Application: | Mineral/Drinking water,Food,Beverage; | Payment Terms: | L/C,T/T; |

| Machinery Test Report: | Provided; | Filling Accuracy: | 0.1ml; |

| Packaging Detail: | mineral water plant project: Wood case.; | Contactor: | Schneider; |

| Filling heads: | 32; | Capping heads: | 10; |

| Machine type: | CGF32-32-10; | Packaging Type: | Cartons,CANS,Bottles,Barrel,Pouch; |

Auto water filling machine introduction

Auto Water Filling Production Line

Auto Water Filling Production Line:

This Wash-filling-capping 3-in-1 unit can finish all the process such as bottle rinsing, filling and sealing fast and stable. the whole process is automatic, suitable for PET bottle, plastic bottle filling mineral water and pure water.Filling way using the gravity or micro pressure filling, make the speed is faster and more stable, so with the same model our machine output is higher and more efficient.The machine adopts advanced Mitsubishi programmable controller (PLC) to control the machine to run automatically, working with inverter running more stable and reliable.The photoelectric sensor detect all part running state, with high degree of automation, easy operation.

A) Washing part of Auto Water Filling Production Line:l All 304 stainless steel rinse heads, water spray style inject design, save water consumption & more clean

lI 304 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

lII 304 stainless steel washing pump

B) Filling Part of Auto Water Filling Production Line :

l High precision filling nozzle, PLC variable signal control, ensure high filling precision & filling smoothly & steadily,

lI Filling volume adjustable in fine rank, same liquid level after filling

lII All 304 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

lV 304 stainless steel filling pump

V no bottle no filling

lI Filling volume adjustable in fine rank, same liquid level after filling

lII All 304 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

lV 304 stainless steel filling pump

V no bottle no filling

C) Capping part of Auto Water Filling Production Line:

.l Place & capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during cappinglI All 304stainless steel construction

lII No bottle no capping,

lV Automatic stop when lack of bottle

lII No bottle no capping,

lV Automatic stop when lack of bottle

Auto water filling machine specification

Auto water filling machine production line

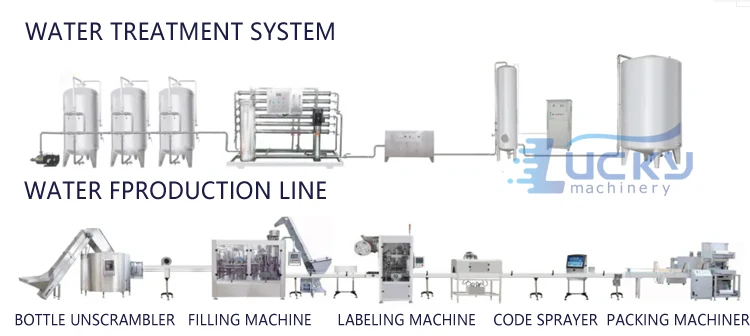

Auto Water Filling Production Line Flow Diagram

1. Full automatic bottle blow machine or Semi automatic bottle blow machine

2. RO water purification machine / UF mineral water filtration machine.

3. Bottle washing filling and capping machine.

4. Shrink sleeve labeling machine or Sticker labeling machine.

5. Date printing machine.

6. Full automatic shrink wrapping packing machine or Semi automatic shrink wrapping packing machine /Carton box packing machine

2. RO water purification machine / UF mineral water filtration machine.

3. Bottle washing filling and capping machine.

4. Shrink sleeve labeling machine or Sticker labeling machine.

5. Date printing machine.

6. Full automatic shrink wrapping packing machine or Semi automatic shrink wrapping packing machine /Carton box packing machine

STEP 1 TREATMENT SYSTEM

STEP 2 BLOWING SYSTEM

STEP 3 FILLING SYSTEM

STEP 4 LABELING SYSTEM

STEP 5 PACKING SYSTEM

Auto water filling machine packing & delivery

Auto Water Filling Production Line:

Company Profile

Lucky machinery- the experienced manufacturer of Auto Water Filling Production Line:

Our main products are water filling machine, carbonated drinks filling machine, juice filling machine, 5 gallon filling machine and all other auxiliary equipment s With years of experience, we can offer the complete solutions to meet your production requirements. We sincerely hope to build a cooperative relationship with customer based on mutual trust, benefits and developments.Advantages:

1)With a more than 10 professionals team to design and develop, which integrates development,research, design, manufacture, technology service and marketing.

2)The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechanical stability.

3)Professional installation team,providing equipment quality installation service which included Installation and commissioning, training and after-sales service.

FAQ

Auto Bottled Water Filling Production Line:

1. This is the first time I use this kind of machine, is it easy to operate?1) English guide video and instruction book are sent to you free together with the machine.

2) Free training course in our factory. Engineers are available to serve overseas.

3) 24 hours technical support by calling, video and email.

2. Do you have a setup and equipment commissioning service?

Yes, we have.The machine was installed and debugged before delivery.You can use the machine directly after receiving it.Of course, we also could let our technologists go to your country to install and debug the machine.

3.How to choose a suitable machine?

we can recommend the most suitable machine according to our experience.

4.What is the warranty period for the equipment?

1 years warranty and machine whole life 24 hours online professional technical support.

5.Payment terms,There are 2 ways to pay money. 1) T/T 2) LC

VIEW MORE

YOU MAY LIKE