Dental lab technical micromotor Strong 204 mini grinder polisher handpiece dental micro motor

- $13.33 / >=50 sets

- 50 sets

- Fuzhou Li Wang Electronic Technology Co., Ltd.

- Fujian, China

- Ms Zhang Susan

| Port: | Fuzhou; | Model Number: | Strong 204; |

| Application: | dental polisher; | Instrument classification: | Class I; |

| Packaging Detail: | bubble bag+foam+carton; | Supply Ability: | 50000 Set/Sets per Month; |

| Max.torque: | 280gf.cm; | Power: | 65W; |

| Collet Chuck: | 2.35mm/3.0mm/3.175mm for optional; | Payment Terms: | L/C,T/T,Western Union,MoneyGram,paypal; |

| Product name: | STRONG 204 102L; | Size: | L131mm*W109mm*H85mm L152mm*26mm; |

| Brand Name: | STRONG DRILL; | Weight: | 2.5Kg; |

| Rotating Speed: | 0~35000rpm; | Package Preview: | ; |

| Type: | Dental Drill & Accessories; | Voltage: | 220V-240V,50Hz 110V-120V,60Hz; |

| Place of Origin: | Fujian China; | Fuse: | 1A; |

Strong 204+102L Dental micro motor portable dental micro motor best quality dental micro motor

●Basic model, Mini-compact design

●Less-vibration standard carbon brush motor

| Controller Box | |

| STRONG 204 | |

| MAX 35,000 RPM | |

| 110V/220(50/60HZ) | |

| DC 0-32V | |

| 3.2N/cm | |

| 131*109*85(mm) | |

| 1.3kg | |

| Handpiece | |||

Dental lab technical micromotor Strong 204 mini grinder handpiece dental micro motor

1. Mini-compact design, easy to carry.

2. Less-vibration standard carbon brush motor

3. Non stage speed control system

4. Rotating converts forwad and reverse control ability

5. Easy maintenance of carboloy brush, no sparkle

6. Disturbance and have better torque and durability

7. Foot pedal for On/Off switch

| Model | |||

| Input Voltage |

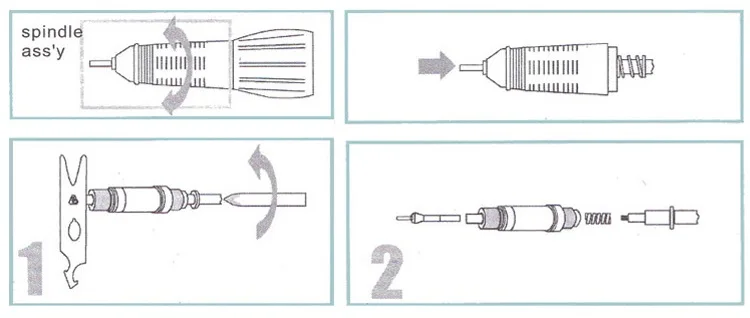

How to Remove and Install the Collet

1.With knurled Chuck Handle in"R"release position and bur or accessory in collet, place triangular hole in Chuck Wrench over triangular flats of Collet head&unscrew the collet counter-clockwise Remove collet.

2. With bur or accessory in new collet, thread into handpiece. Place triangular hole in Chuck Wrench over triangular flats of Collet head and tighten the collet clockwise. Be careful not to over-tighten. Test to insure that new collet releases accessory smoothly in the "R" released position. Test to insure that new collet holds firmly in the "S" secure position and spindle rotates freely.

Changing Accessories

Burs and other accessories can be inserted or removed from the handpiece collet when the collet is open. To open the collet:

1. Turn off the motor using the Motor On/Off Switch 3 and the Power Switch.

2. Twist the Chuck Handle in the "R" or release direction (clockwise) until the raised indicator bar clicks into the far left mark on the silver center ring.

3. Remove the accessory and replace with another accessory. Insert the 'new' accessory shank fully into the collet for maximum support. You should feel it touch the back of the collet.

4.Twist the knurled Chuck Handle toward the "S" or secure position by turning counter-clockwise until it snaps to lock the collet. The accessory and the collet will be able to spin freely. The raised collet indicator bar will be above the far right mark in the silver center ring. Note: The intermediate position between "S" and "R" holds both the spindle and the accessory in a locked position. This is useful to unscrew an over-tightened mandrel screw.

• ONLY use accessories rated for 35,000 rpm or higher speeds when operating this micromotor.safe operation when using accessories with head diameters of more than 3/32″ (2mm).

• ALWAYS observe the manufacturer's maximum speed rating when using any accessory.

• NEVER use or continue to use any accessory which appears to be damaged, loose, vibrating, bent, or out of balance. Inspect each accessory for cracks or flaws before use.

• ALWAYS insert the shank or arbor of an accessory or mandrel into the collet or chuck of the handpiece as far as possible in order to provide proper support and close the collet or chuck securely.

• NEVER use excessive side pressures which may tend to bend or break the shank or arbor of an accessory. Let the speed of the accessory do the work.

• DO NOT stall the motor by jamming or using excessive pressure on the mounted point, buff, wheel or accessory. This can result in damage to the motor.

• WEAR a dust protector, mask or respirator to prevent the inhalation of harmful dust or debris from grinding, carving or other operations performed with this power tool.

• NEVER operate with a damaged power cord. If the power cord or plug to the handpiece is damaged, repair or replace immediately.

• USE a dust collector (vacuum system) to pull sawdust, grinding dust, or other debris away from the work area and the micromotor intake vents.

• NEVER turn on or start the Handpiece while chuck is in open (unlocked) position. This can damage the handpiece. Make sure that a bur is installed and secured in the collet, that the spindle is NOT locked and that the bur can spin freely. Always operate and store it with a bur or other accessory in the chuck and with the chuck in the closed position.

• DO NOT operate the handpiece in the presence of any flammable liquid or gas.

45000RPM

brush micromotor

[GJ-G800+XM]

50000RPM

brushless micromotor

50000RPM

brushless micromotor

35000RPM

brush handpiece

[107 double lock]

[Strong 102L]

35000RPM

brush handpiece

[Dental burs]

[Nail bits]