Disposable foam board making machine/meal box vacuum forming production line/PS foam board fast food board making machine

- 1 piece

- Longkou Haiyuan Plastic Machinery Co., Ltd.

- Shandong, China

- Ms Elle Shung

2.PS foam food container production line, PS foam plate production line

3. Foam food box making machine, foam food tray machine, foam food tray machine

4. Takeaway food box making machine, foam food container machine, foam food box making machine

5.PS foam absorbent tray making machine, food container vacuum forming machine

6. Foam egg tray making machine, foam burger box making machine, pizza box making machine

7.PS foam ceiling machine

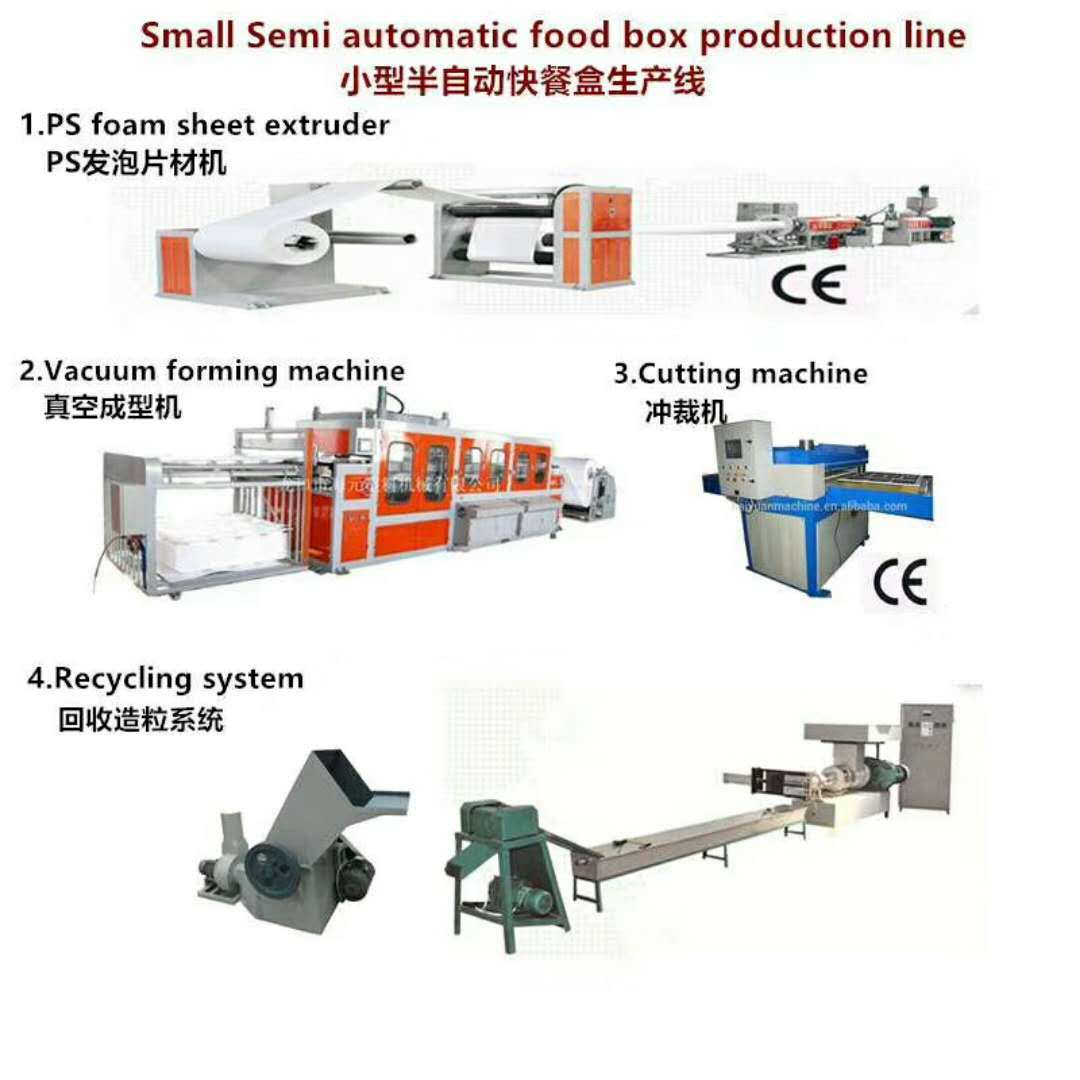

* PS foam sheet extruder + * Vacuum forming machine + * Recycling machine

1.PS foam sheet extrusion production line

The PS foam sheet extrusion production line adopts gentian two-stage series high foaming technology. The raw material is general-purpose polystyrene particles. During the extrusion process, the foaming agent is injected at high pressure. After extrusion, foaming, cooling, shaping, and traction, Rewind into finished PS foam sheet rolls.

In our factory, we not only produce extruders, but also produce PS foam sheet rolls. We can produce sheet rolls of different thicknesses, different hardnesses, and different colors. If you have no experience, don’t worry, we can help you! Treadmills can be seen when you visit our factory

PS foam sheet extrusion production line parameters | ||||||||||

scope | unit | HY-75/90 | HY-105/120 | HY-110/130 | HY-135/150 | |||||

capacity | kg/hour | 80-100 | 200-240 | 230-260 | 280-360 | |||||

Board thickness | mm | 1-4 | 1-4 | 1.5-5 | 2-5 | |||||

Board width | mm | 640-1080 | 640-1080 | 800-1080 | 900-1080 | |||||

Foaming rate | 10-22nd | |||||||||

Cooling method | Air cooling, water cooling | |||||||||

Cutting method | single | |||||||||

Butane gas pressure | MPa | 0.9-1.2 | ||||||||

Installed power | kilowatt | 160 | 200 | 260 | 320 | |||||

Installation partition | rice | 24*6*3 | 30*6*3 | 32*6*3 | 35*8*63 | |||||

power supply | Three-phase 380v50Hz Three-phase 220v60Hz | |||||||||

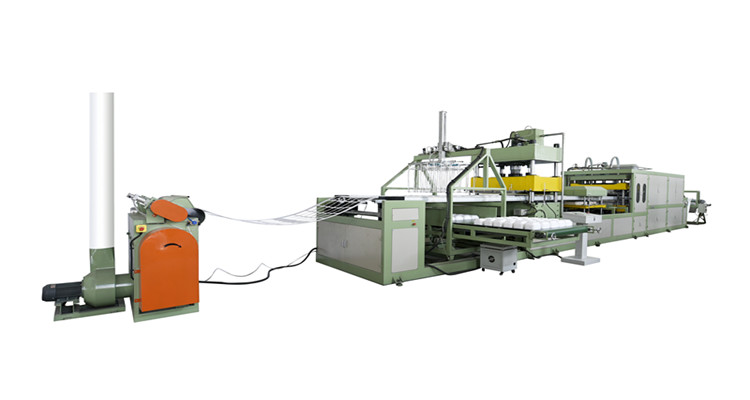

2. Disposable foam board making machine/meal box vacuum forming production line/PS foam board fast food board making machine

Disposable foam board making machine/meal box vacuum forming production line/PS foam board fast food board making machine feature

1) Takeaway food container making machine Vacuum forming, cutting and stacking integration

2) Foam tableware machine,Foam board foam cup machineIt can produce PS foam food boxes, disposable foam plates, take-out food containers, foam egg trays, hamburger boxes, foam food boxes, foam food plates, foam bowls, fruit plates, foam absorbent plates, foam ceilings, etc. It is widely used in packaging of hot and frozen food in supermarkets and stores.

3) Foam box forming machine and foam food tray machine use far-infrared ceramic heaters and heating tubes in the heating area to enable the machine to obtain the most stable temperature.

4) The PS foam lunch box machine adopts a temperature digital system to facilitate workers to quickly understand the temperature of each heating zone.

5) Disposable foam board making machineAdopt PLC controller and touch screen to control the working programmer. PLC can store more than 10 sets of mold information. There is no need to reset the data when changing molds, making it easy to operate.

Disposable foam board making machine/meal box vacuum forming production line/PS foam board fast food board making machine pparameter | ||||||||

scope | unit | HY-1100/1100 | HY-1100/1250 | HY-1100/1400 | ||||

Molding area | mm | 1100*1100 | 1100*1250 | 1100*1400 | ||||

Cut off height | mm | 160 | ||||||

Production efficiency | s/mold | 3-4 | ||||||

capacity | pieces/day | 400,000 pieces | 500,000 pieces | 600,000 pieces | ||||

Installation dimensions | rice | 19*6*3 | 21*6*3 | 24*6*3 | ||||

Install powder | kilowatt | 150 | 160 | 180 | ||||

power supply | Three-phase 380v50Hz 220v60Hz | |||||||

3. Crusher and recycling granulator