EPDM TPU FKM ACM SBS NBR Silicone Rubber Silicone Syringe O-ring O-ring Seal Kit Cartridge Cover Rubber NBR Seal O-ring

- $0.002 / >=100 pieces

- 100 pieces

- Fujian Jingteng Rubber Industry Co., Ltd.

- Fujian, China

- Mr Henry Chan

PRODUCT DETAIL

| Material: | NBR/FKM/HNBR/FFKM/EPDM/Silicone etc. | Supply capacity: | 650000 pieces per month |

| temperature: | -20℃-+260℃ | payment terms: | L/C, Western Union, T/T, MoneyGram, PayPal |

| Certificate: | ISO9001 | feature: | Oil/Chemicals/High Temperature/Waterproof/Abrasion Resistant |

| port: | Fuzhou/Xiamen | size: | Rubber O-ring seals, ID*C/S(mm) |

| Origin: | Fujian, China, Fujian, China | OEM: | accept |

| color: | Black/Brown/Green/Yellow/Blue/Transparent/Red etc. | hardness: | 50-90 Shore |

| year established: | Year 2009 | Package preview: | |

| Packaging Details: | 200pcs in poly bags, 15 bags in cartons, OEM is available. |

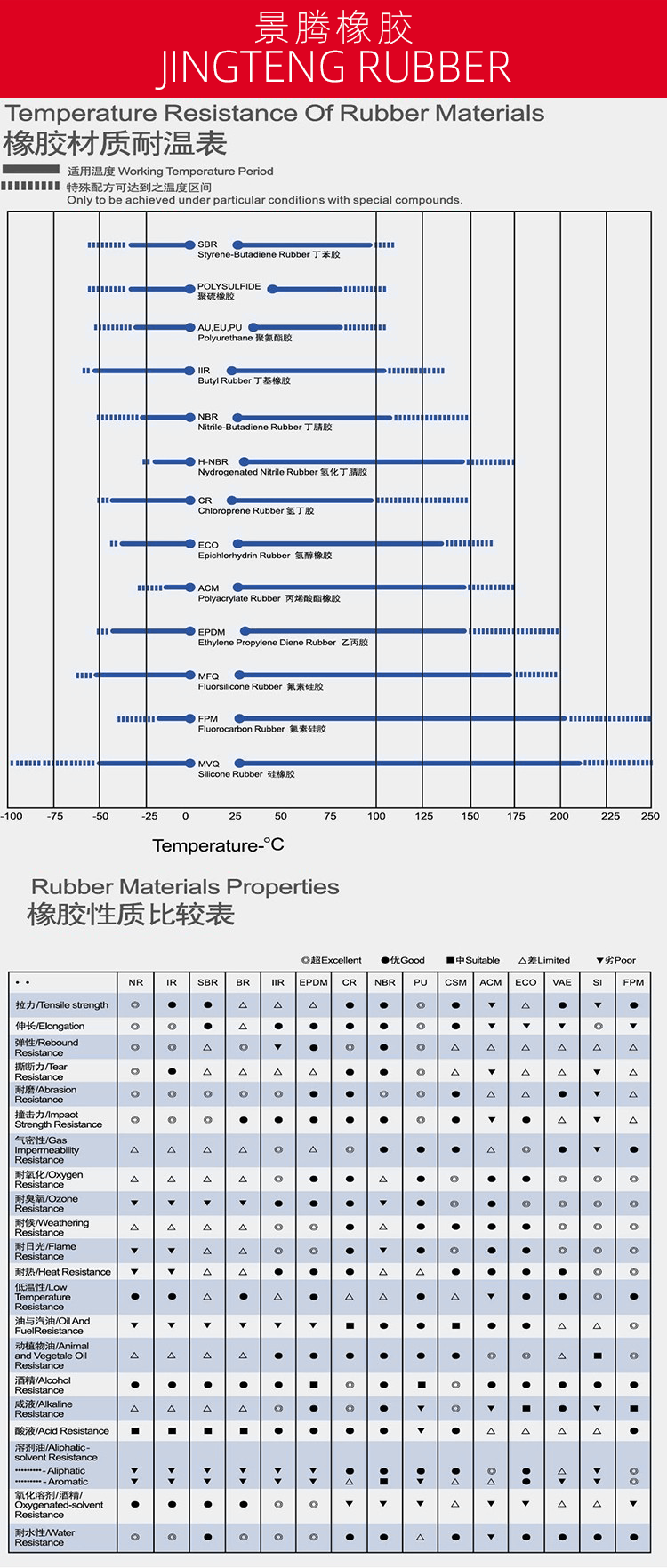

O-rings are available in the following elastomers:

Afras? Or Kalrez? (FFKM) Acrylate Rubber (ACM) Butyl Rubber (IIR) EPDM (EPR, EPDM) Ethylene Acrylate Rubber (AEM) Fluorocarbon Rubber (FKM/FPM) Fluorosilicone Rubber (FVMQ) Hydrogenated Butyl Rubber Nitrile Rubber (HNBR) Liquid Silicone Rubber (LSR) Neoprene Rubber (CR) Nitrile Rubber (Buna-N/NBR) Natural Rubber (NR) Polyurethane (PU) Silicone Rubber Styrene Butadiene Rubber (SBR)

❖ If you need a special o-ring compound, we can develop one for you.

Afras? Or Kalrez? (FFKM) Acrylate Rubber (ACM) Butyl Rubber (IIR) EPDM (EPR, EPDM) Ethylene Acrylate Rubber (AEM) Fluorocarbon Rubber (FKM/FPM) Fluorosilicone Rubber (FVMQ) Hydrogenated Butyl Rubber Nitrile Rubber (HNBR) Liquid Silicone Rubber (LSR) Neoprene Rubber (CR) Nitrile Rubber (Buna-N/NBR) Natural Rubber (NR) Polyurethane (PU) Silicone Rubber Styrene Butadiene Rubber (SBR)

❖ If you need a special o-ring compound, we can develop one for you.

❖ Strong flexibility

We can produce sealing products with good stretch ability to meet customer's special FPR stretch

❖ High precision

We strictly control every production detail to ensure product accuracy

❖High quality products

The surface of the product is smooth, free from flashes and blemishes

❖various materials

Smooth and textured surface without burrs

We can produce sealing products with good stretch ability to meet customer's special FPR stretch

❖ High precision

We strictly control every production detail to ensure product accuracy

❖High quality products

The surface of the product is smooth, free from flashes and blemishes

❖various materials

Smooth and textured surface without burrs

model | NBR, EPDM, SILICONE, FKM, SBR, NR, etc. |

Hardness range | 20-90 Shore A |

color | Any color can be customized |

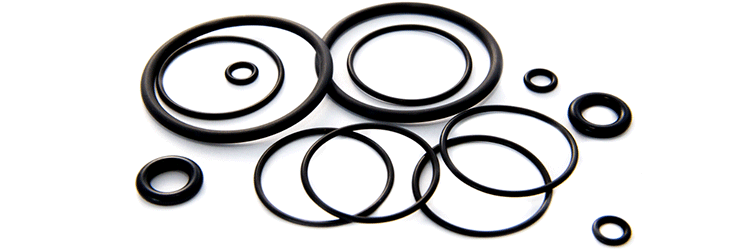

size | AS568, PG and non-standard O-rings |

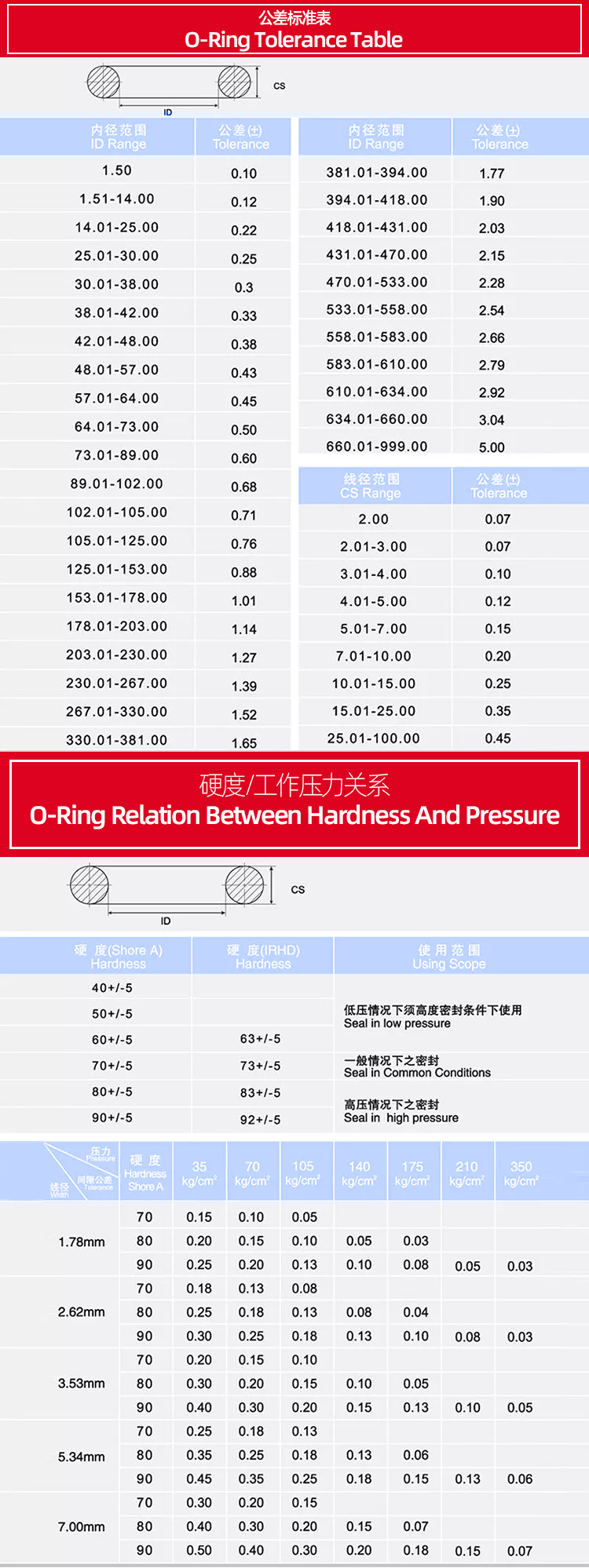

Tolerance standard | AS568, ISO2768-M or ISO3302-1:2014 M2 level |

application | Applicable to all industries |

Construction time | Year 2009 |

Serve | ODM/OEM |

Certificate | ISO9001, RoHS, REACH |

Factory location | Ningde City, Fujian Province, China |

Features

NBR (Nitrile Butadiene Rubber)

Temperature Range: -30°C to 125°C Hardness: 40-90 Shore A Uses: Oil Resistant Situations Advantages: Excellent oil resistance and stability, versatile and cheap

FKM (Viton)

Temperature range: -20°C to 250°C Hardness: 50-90 Shore A Uses: Oil and chemical applications Advantages: Wear resistance, acid and alkali resistance, high temperature applications

Silicone rubber (Q, MQ, VMQ, PVMQ)

Temperature range: -60°C to 225°C Use: Food application (approved) Advantages: Good heat resistance, cold resistance, lubricating oil resistance, water resistance

EPDM rubber, EPDM rubber(ethylene propylene rubber)

Temperature Range: -50°C to 150°C Hardness: 40-90 Shore A Advantages: Excellent ozone resistance. Heat resistance, steam resistance, cold resistance, LLC resistance

HNBR (hydrogenated nitrile rubber)

Temperature range: -30°C to 160°C Hardness: 50-90 Shore A Advantages: Excellent ozone resistance. Heat resistance, mechanical strength, ozone resistance are better than NBR

CR (Neoprene)

Temperature range: -44°C to 120°C Hardness: 60-90 Shore A Advantages: Excellent mechanical strength and fatigue resistance

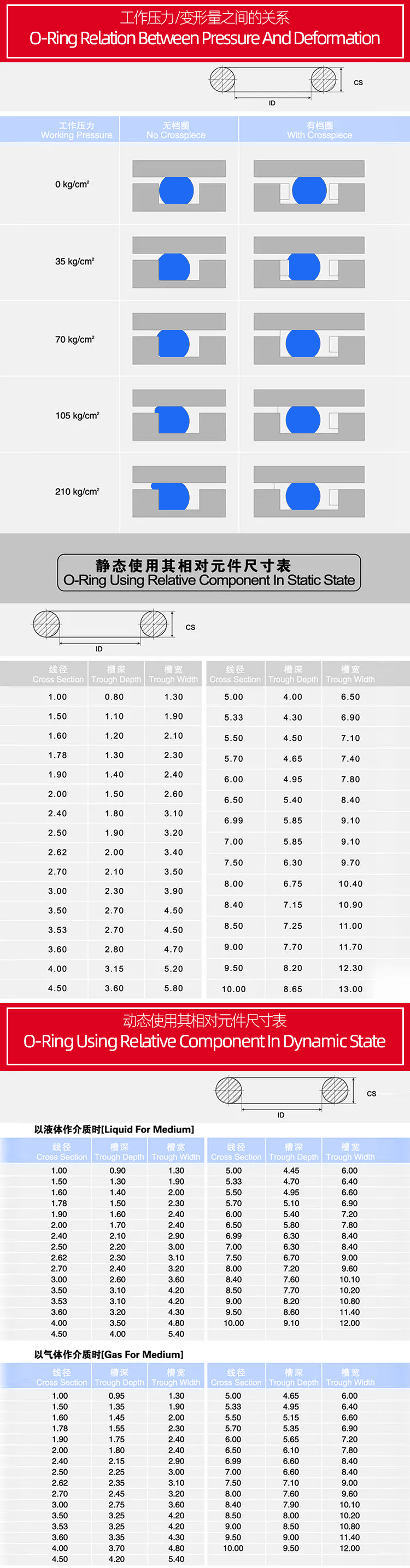

Technical Information

VIEW MORE