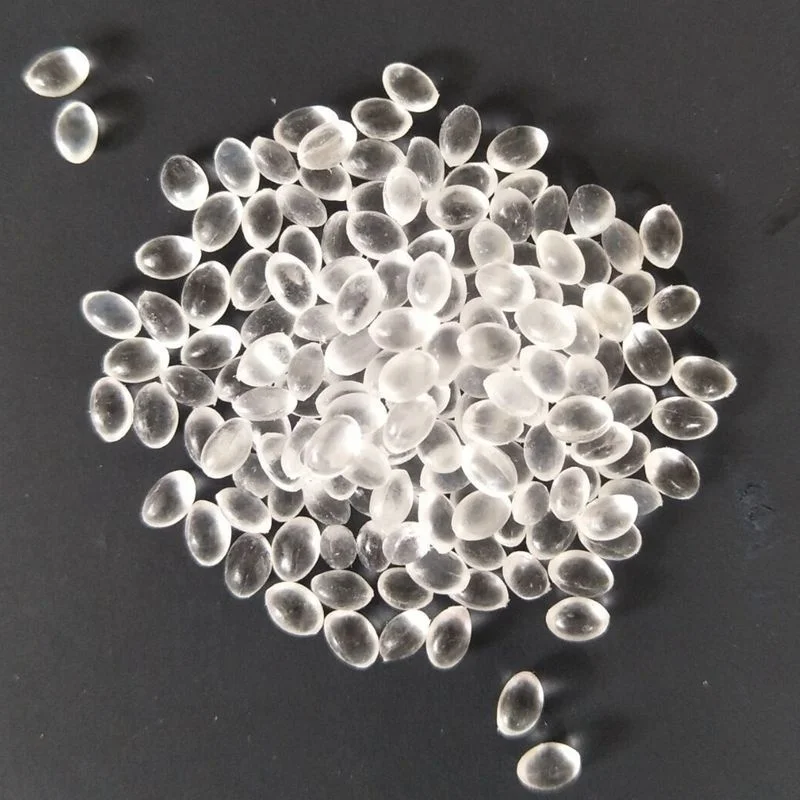

EVA Resin Granule CAS NO,:24937-78-8

- $1.20 / >=1000 kilograms

- 1000 kilograms

- Xingtai Dongchuang Automobile Co., Ltd.

- Hebei, China

- Ms alisa zhang

| Application: | Shoe making Industry; | Color: | Transparent; |

| Port: | tianjin; | Appearance: | Elastic Granules; |

| Place of Origin: | Hebei, China; | Usage: | Making EVA Slippers; |

| Type: | Vrigin; | Package Preview: | ; |

| Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; | Supply Ability: | 200 Tons per Month; |

| Keyword: | EVA Foaming Granules; | Brand Name: | XT DONGCHUANG; |

| Name: | Ethylene Vinyl Acetate Resin; | Material: | raw materials; |

| Model Number: | eva; | Product name: | EVA Ethylene-vinyl Acetate Copolymer; |

| Packaging Detail: | Wonven bag Carton packaging, plastic bag packaging, or according to customer requirements; |

EVA(Ethylene Vinyl Acetate Copolymer)

EVA is copolymerized with ethylene and acetic acid. Its Chinese chemical name is ethylene vinyl acetate copolymer (ethylene vinyl acetate copolymer), and its English chemical name is ethylene vinyl acetate copolymer. EVA has a wide range of application fields. China's annual market consumption is increasing, especially in the shoemaking industry. It is used in the soles and interior materials of medium and high-grade tourist shoes, mountaineering shoes, slippers and sandals. It is also widely used in the field of new energy, such as photovoltaic materials, solar cell adhesives, etc.

|

Product Name |

EVA Resin / EVA Granules / EVA Raw Material / Ethylene Vinyl Acetate Copolymer |

||

|

Color |

White,Yellow,Red,Blue or Customized |

||

|

Glossiness |

Glossy |

||

|

Odor |

Smell or Non-smell |

||

|

Wear Resistance |

Wearproof |

||

|

Scrappage |

Low |

||

|

Ratio(expansion rate) |

As customers’ different mould expansion. Usually ratio is 160 or 165. Mix S and L to make EVA finished products. |

||

|

Hardness |

Soft |

Hardness 40-50 |

|

|

|

Medium |

Hardness 50-60 |

|

|

|

Hard |

Hardness 60-65 |

|

|

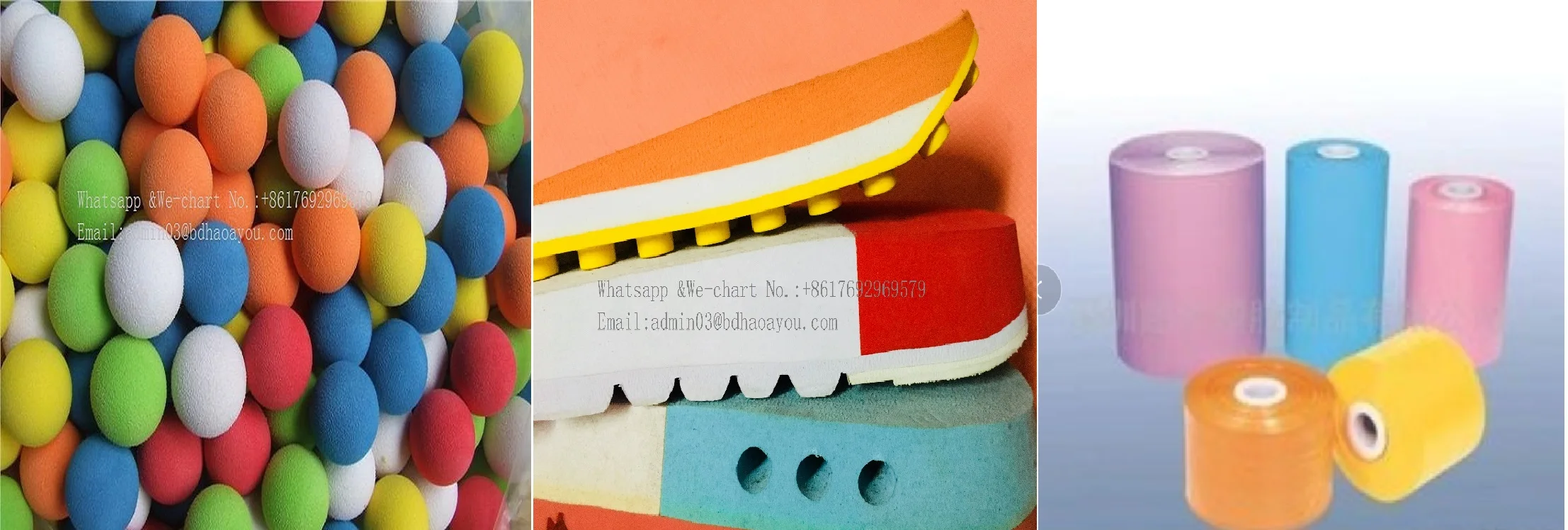

Application |

1.Eva granules/pellets (also named Eva foam materials) are widely used to produce Eva slippers, sandals, shoe sole, rain boots, road sign, shopping baskets, toys, baby buggy tires, foam rollers, bicycle seat cushion etc. 2.Injection, Mould foaming, Secondary foam foaming in the mould

|

||

|

Advantages |

1. Light weight. 2. High Elasticity. 3. Heat & cold resistence. 4. Water resistance. 5. Non-toxic & Environmental-friendly. 6. No odour. 7. Customized Formula in terms of color, hardness, ratio and chemicals. |

||

1. Do we provide free sample?

A:Of course, just to tell us your specific require, then we will arrange the sample to you, if you just need a sample to check the quality, we will provide you sample for free, as long as you afford the express freight charges, if your trial order meet our MOQ, we will return freight charges later.

2. How can i get a sample to check your quality?

A: After price confirmation, you can require for samples to check quality.

1 kg free sample for each kind of resin, deliver in 3-5 working days.

3. How did you guarantee the quality?

A: In production, we will control the quality strictly, we have our own inspection to check the specification, and our product can accept any the third party inspection.

4. What is the packing?

A: Regular packing: Waterproof sack with 25Kg/bag woven bag.

5. Why you should choose us?

A: 1)Excellent physical stability and performance

2) High Working efficiency

3) Harmless to health and friendly to environment

4) Great dispersion, smooth, no flow line, no block, no spot

5) We will answer your questions within 24 hours. Do not hesitate to ask us.