Eco-Friendly Reusable Free Copas Menstrual Silicone Set Certified Personalized Oem Menstrual Cups 100 Menstrual Cups

- $0.45 / 2 - 2999 pieces

$0.37 / 3000 - 29999 pieces

$0.26 / >=30000 pieces - 2 pieces

- DH (Shandong) Health Technology Co., Ltd.

- Shandong, China

- Ms Cherry Tseng

PRODUCT DETAIL

| Serve: | OEM label | port: | Qingdao |

| brand: | DH | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

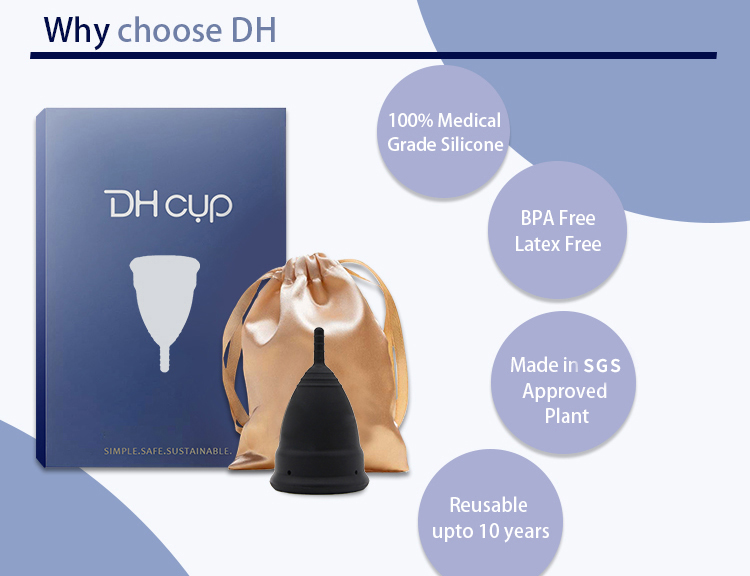

| Material: | silicone | Origin: | Shandong Province, China |

| volume: | 20-35ml | sample: | Free samples |

| Certificate: | ISO 13485, ISO 10993, RoHs, Reach, Ukas, CE | product name: | menstrual cup |

| size: | XS(20ml)/S(25ml)/L(30ml) | Function: | female menstrual period |

| Can be reused: | Can be reused more than 150 times | Package preview: | |

| model: | HDMC-903 | ID: | custom logo |

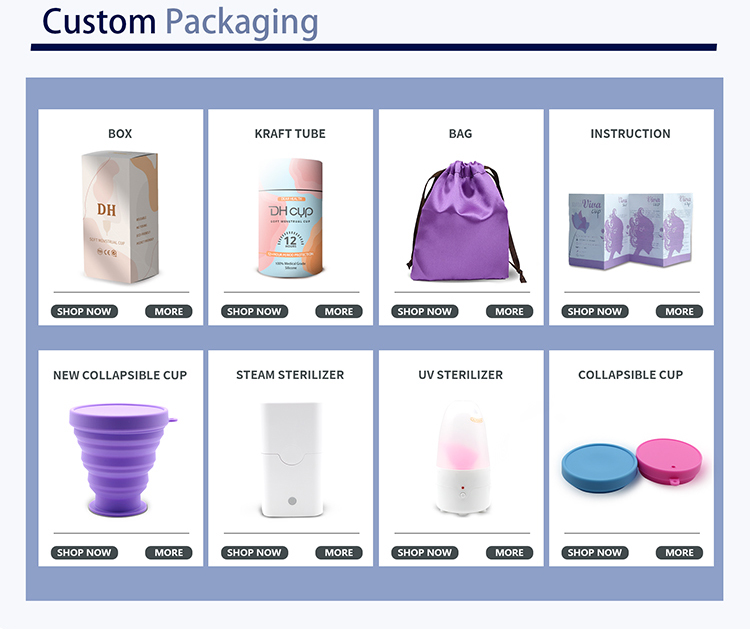

| Packaging Details: | opp bag/cup+cloth bag+manual+box/can be customized | Supply capacity: | 300 million pieces per year |

Model: | DHMC-902 |

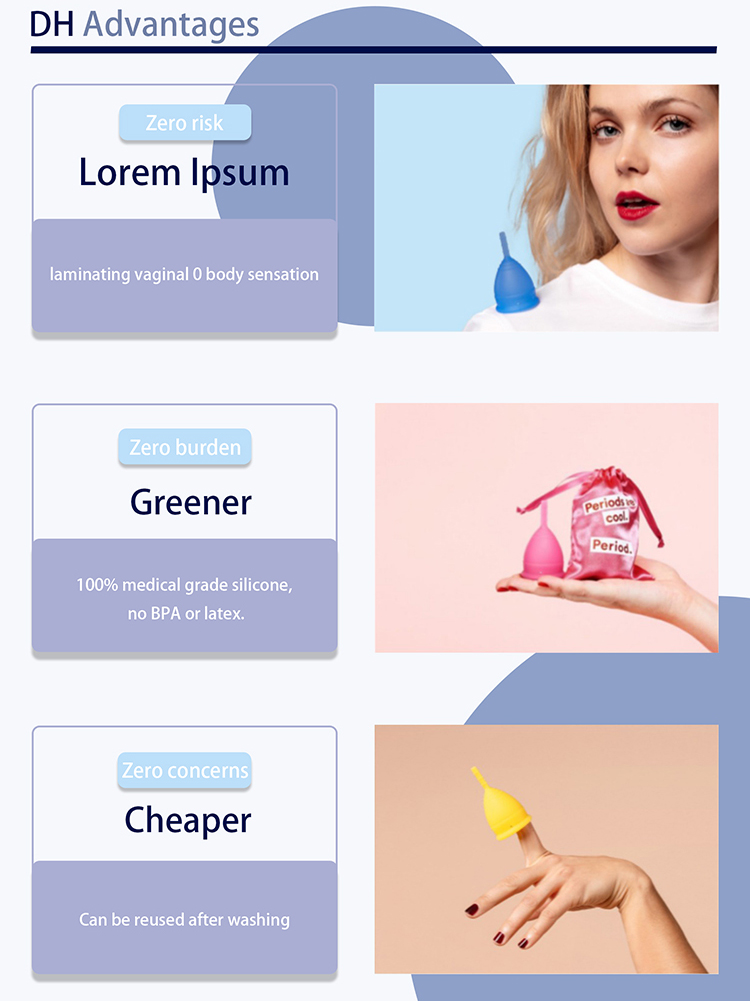

feature: | Sealed, no leakage, no bacteria, safe and insensitive, refreshing and comfortable, environmentally friendly and economical Money, easy to move, large blood storage, beautiful, easy to use, |

temperature: | -40℃~230℃ |

size: | XS (extra small 25ml/ S (small 35ml)/ L (large 45ml) and customized |

weight: | XS: 8.8g, S: 13g, L: 16g |

Material: | Medical Silicone Grade |

color: | custom made |

brand: | OEM brand/DH brand |

type of packaging: | opp bag/cup+cloth bag+manual+box/can be customized |

usage time: | day and night |

design: | free design |

OEM/ODM: | usable |

Origin: | Shandong China |

sample: | Contact the DH CRM team for a free sample |

MOQ: | 1 |

deliver goods: | About 7-25 days after receiving the deposit and confirming the package layout |

Qingdao, China | |

payment terms: | T/T 30% as deposit, T/T 70% before shipment |

L/C/DDP/D/A, OA, /Western Union, Moneyggram, Paypal, |

FAQ

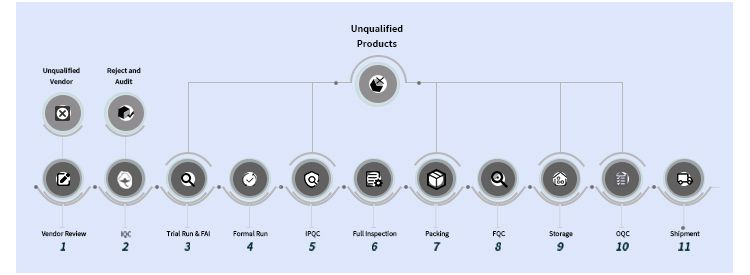

1. The design of the artwork.

Artwork design generally draws and produces artwork based on samples or drawings provided by customers.

Generally use drawing software, such as CDR or Al software. If the customer cannot provide samples, we can cooperate with the customer for free according to the customer's requirements. Design and make a little bit.

2. Make molds.

According to the design draft, make the steel mold. The production technology requirements of some silicone rubber molds are relatively high, and the time is relatively long. Generally, the mold opening cycle is calculated as five days, and the mold is completed in 7-15 days. After the proofing board confirms that the structure is correct, it can be mass-produced.

3. Toning

According to the color specified by the customer or according to the color of the customer's sample, our company's color ratio is

Alignment (above 95%), color difference is very small.

4. Approved materials

According to the requirements of customers, different silicone raw materials are used for production. If there are domestic ordinary rubber materials, high tensile (pneumatic rubber), imported rubber materials, the hardness of silica gel varies from 30 degrees to 80 degrees, and 60 degrees is commonly used. The company has professional measuring instruments.

5. Upper mold making

Send the colored silicone raw materials to the production department for production.

6. Product inspection

Carry out a full inspection of the first product produced, whether it meets the product specifications, whether it meets the color required by the customer, whether it is dirty, missing materials and other appearance defects. If there are any discrepancies, they will all be discarded.

7. Pruning

Each product will feature a phoenix. After the raw materials pass the inspection, the products are sent to the process department for phoenix treatment. After the phoenix is processed, it is a finished product.

8. Appearance function inspection

The finished product is sent to the quality inspection department to check whether there is any bad treatment

The front side, etc., after passing the inspection, carry out functional tests such as tensile, torsion, and UV.

9. Packaging

After all, the product has passed the test and is assembled from silicone semi-finished products of different colors

According to customer requirements, and then packaged (note: different packages, different charges).

10. Shipment quality control

After the packaging is completed, the quality inspection department will check whether the label, color, quantity, etc. of each box are consistent with the order. If there are no issues, the box will be sealed and delivered to you.

Generally use drawing software, such as CDR or Al software. If the customer cannot provide samples, we can cooperate with the customer for free according to the customer's requirements. Design and make a little bit.

2. Make molds.

According to the design draft, make the steel mold. The production technology requirements of some silicone rubber molds are relatively high, and the time is relatively long. Generally, the mold opening cycle is calculated as five days, and the mold is completed in 7-15 days. After the proofing board confirms that the structure is correct, it can be mass-produced.

3. Toning

According to the color specified by the customer or according to the color of the customer's sample, our company's color ratio is

Alignment (above 95%), color difference is very small.

4. Approved materials

According to the requirements of customers, different silicone raw materials are used for production. If there are domestic ordinary rubber materials, high tensile (pneumatic rubber), imported rubber materials, the hardness of silica gel varies from 30 degrees to 80 degrees, and 60 degrees is commonly used. The company has professional measuring instruments.

5. Upper mold making

Send the colored silicone raw materials to the production department for production.

6. Product inspection

Carry out a full inspection of the first product produced, whether it meets the product specifications, whether it meets the color required by the customer, whether it is dirty, missing materials and other appearance defects. If there are any discrepancies, they will all be discarded.

7. Pruning

Each product will feature a phoenix. After the raw materials pass the inspection, the products are sent to the process department for phoenix treatment. After the phoenix is processed, it is a finished product.

8. Appearance function inspection

The finished product is sent to the quality inspection department to check whether there is any bad treatment

The front side, etc., after passing the inspection, carry out functional tests such as tensile, torsion, and UV.

9. Packaging

After all, the product has passed the test and is assembled from silicone semi-finished products of different colors

According to customer requirements, and then packaged (note: different packages, different charges).

10. Shipment quality control

After the packaging is completed, the quality inspection department will check whether the label, color, quantity, etc. of each box are consistent with the order. If there are no issues, the box will be sealed and delivered to you.

VIEW MORE

YOU MAY LIKE

Other Products

-

Wholesaler Grade B Cheap Disposable Feminine Pads Sanitary Napkin For Women Ladies$0.03 - $0.05 / piece

Wholesaler Grade B Cheap Disposable Feminine Pads Sanitary Napkin For Women Ladies$0.03 - $0.05 / piece