Electric Bending Machine Galvanized Sheet Bending Machine Sheet Metal Bending Machine Sheet Metal Bending Machine

- $1450.00 /set

- 1 set

- Zhenjiang Lifeng Machinery Technology Co., Ltd.

- Jiangsu, China

- Mr doctson liu

PRODUCT DETAIL

| payment terms: | wire transfer | Bending Thickness(mm): | 0.3 - 1.5 mm |

| port: | Shanghai Port | Mechanical test report: | if |

| Bending Length(mm): | 1300 mm | Applicable industries: | Hotels, Clothing Stores, Retail, Energy and Mining, Food and Beverage Stores, Printing Stores, Household, Machinery Repair Shops, Manufacturing Plants, Food and Beverage Factories, Farms, Food Stores, Advertising Agencies, Restaurants, Construction Works, Building Materials Stores |

| Health status: | new | Core components: | Engines, bearings, motors, pumps |

| Dimensions (L*W*H): | 2200*700*1100 mm | Origin: | Jiangsu, China |

| Warranty: | 1 year | Weight (kg): | 450 |

| Package preview: | Video outbound inspection: | if | |

| brand: | docson | Material/Metal Processing: | Alloy, Brass/Copper, Stainless Steel, Aluminum |

| Packaging Details: | wooden box for machine | Main selling points: | competitive price |

| Core component warranty: | 1 year | Showroom location: | not any |

| Marketing Type: | normal product | Voltage: | 380V/50Hz/three-phase |

| Supply capacity: | 50 sets per month |

Specification

Model | Minimum folding angle (°) | Weight (kg) | Thickness (mm) | Maximum processing length (mm) |

WSD1.5*1300 | 60 | 400 | 0.3-1.5 | 1300 |

WSD1.5*1500 | 60 | 450 | 0.3-1.5 | 1500 |

WSD1.5*2000 | 60 | 500 | 0.3-1.5 | 2000 |

WSD1.5*2500 | 60 | 600 | 0.3-1.5 | 2500 |

WSD1.5*3000 | 60 | 650 | 0.3-1.5 | 3000 |

TDFD1.5*1300 | 60 | 450 | 0.3-1.5 | 1300 |

TDFD1.5*1500 | 60 | 500 | 0.3-1.5 | 1500 |

TDFD1.5*2000 | 60 | 550 | 0.3-1.5 | 2000 |

TDFD1.5*2500 | 60 | 650 | 0.3-1.5 | 2500 |

TDFD1.5*3000 | 60 | 700 | 0.3-1.5 | 3000 |

Main features:

Electric folding machineIt can be used for galvanized bending and flanging of less than 2mm galvanized bending and flanging of sheet metal, steel plate and color plate supporting equipment of rectangular air duct production line. And can be used in electric lighting lamps, hardware tools, air-conditioning equipment, sheet metal processing and other industries. The machine adopts a heavy-duty chassis and arc steel frame to ensure a sturdy and durable structure, and uses a full-copper core brand motor with low temperature rise efficiency. Simple operation, manual operation, greatly reducing labor intensity and manual operation cost.

● Heavy duty steel frame provides precise bends; ● Extended fingers allow bending of pans or boxes to a depth of 200mm; ● Scale scales on both sides of the machine for readout take the guesswork out of bending angles; ● Ground segmented fingers Can be repositioned to accommodate a variety of applications; ● Safety top beam support stop bar located on the right side of the machine; ● Quickly adjust crosshead to accommodate varying material thicknesses; ● Includes rear manual backgauge.

Pure copper core motor

Durable, the service life is 10 times that of ordinary models.

Angle arm

Adjustable panel cutting tool can process different sizes according to different needs.

electrical box

Brand electrical box is selected, quality and safety are guaranteed.

Common size

TDF size

The material of the knife mold is tool steel, which has small bending deformation and long service life. You can choose the type of machine you need according to the processed productsMetal plate.

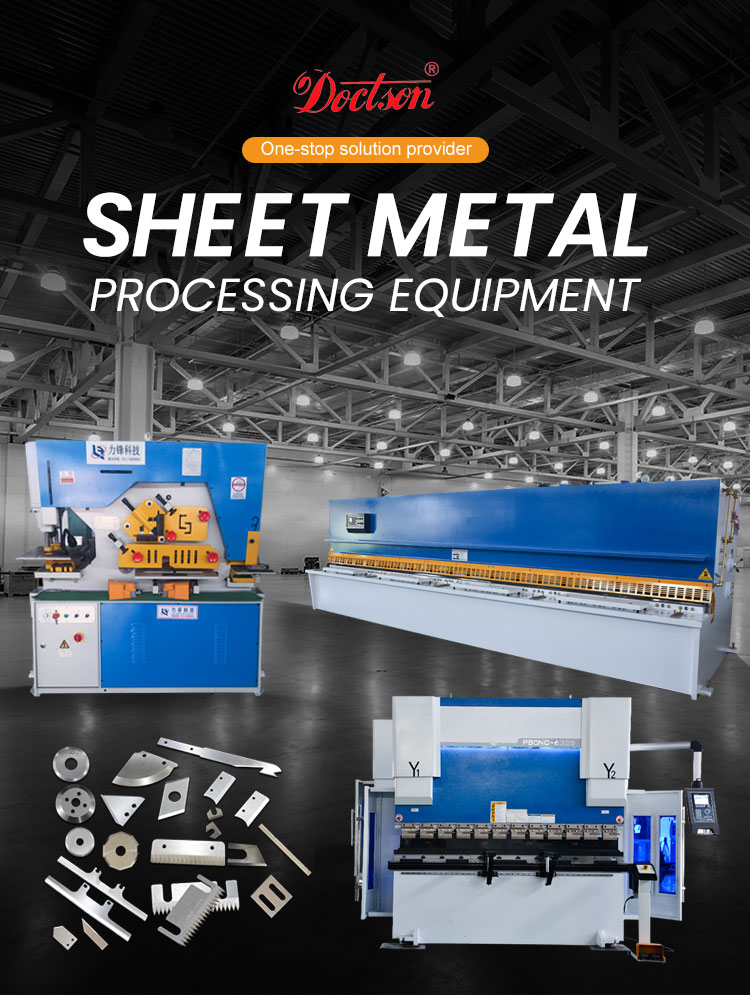

Product Image

VIEW MORE

YOU MAY LIKE