Factory direct sales guaranteed galvanized steel sheet low price Dx51d Dx52d Dx53d dx51d z140 galvanized sheet

- $725.00 / 1 - 9 pieces

$690.00 / >=10 pieces - 1 piece

- Shandong Shengda Iron And Steel Group Co., Ltd.

- Shandong, China

- Ms doreen liu

PRODUCT DETAIL

| grade: | Spcc Secc Dx51d Dx52d Dx53d | application: | Make pipes, cut sheets, make gadgets, make corrugated sheets, make containers, make fences |

| length: | based on customer's needs | Packaging Details: | Standard export seaworthy packaging or as required |

| technology: | Cold rolled base | coating: | Z10-Z29 |

| Certificate: | API, ce, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, JIS, GS, ISO9001 | type: | steel coil |

| Supply capacity: | 100,000 tons per month | delivery time: | 8-14 days |

| To oil or not to oil: | lightly oiled | Origin: | Shandong China |

| payment terms: | L/C, D/P, D/P, T/T, MoneyGram | hardness: | full hard |

| Processing services: | Welding, punching, cutting, bending, decoiling | brand: | Shengda |

| Skin Pass: | Yes | thickness: | 0.12mm-6mm |

| standard: | AiSi, ASTM, bs, DIN, GB, JIS | port: | Qingdao Port, Tianjin Port |

| tolerant: | ±1% | Spangle type: | regular sequins |

technical standard | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 | ||||||

steel grade | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490, SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340, SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); or customer's Require | ||||||

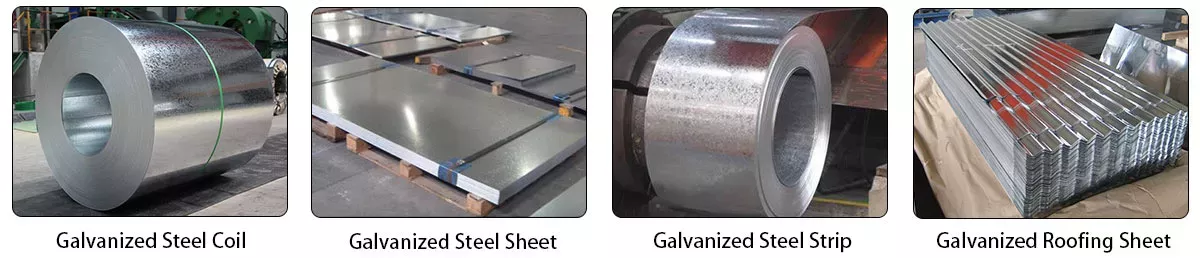

type | Coil/Sheet/Plate/Strip | ||||||

thickness | 0.12-6.00mm, or customer requirements | ||||||

width | 600mm-1500mm, according to customer requirements | ||||||

coating type | Hot dip galvanized steel (HDGI) | ||||||

Galvanized layer | 30-275 g/m² | ||||||

surface treatment | Passivated (C), Oiled (O), Painted (L), Phosphated (P), Untreated (U) | ||||||

surface structure | Normal spangle coating (NS), minimum spangle coating (MS), spangle free coating (FS) | ||||||

quality | Passed SGS, ISO certification | ||||||

ID | 508mm/610mm | ||||||

Coil weight | 3-20 metric tons per roll | ||||||

pack | Waterproof paper is the inner package, galvanized steel or coated steel is the outer package, side guards, and then wrapped Seven steel strips. Or according to customer requirements | ||||||

Export market | Europe, Africa, Central Asia, Southeast Asia, Middle East, South America, North America, etc. | ||||||

product description

Hot-dip galvanizing is the reaction of molten metal and iron matrix to form an alloy layer.

Thus bonding the substrate and the plating. Hot-dip galvanizing is pickling of steel

Parts first. In order to remove iron oxide on the surface of steel parts, after pickling,

Wash in ammonium chloride or zinc chloride aqueous solution or a mixed solution of ammonium chloride and zinc chloride. Then into the hot-dip coating tank. Hot-dip galvanizing has

Uniform coating, strong adhesion, long service life and other advantages.

Steel surface coating and layer diagram

surface structure

production process

01. Anticorrosion:13 years in the heavy industrial area, 50 years in the ocean, 104 years in the suburbs, and 30 years in the countryside

City.

02. Cheap:The cost of hot-dip galvanizing is lower than other coatings.

03. Reliable:The galvanized coating is metallurgically bonded to the steel, forming part of the steel's surface, so the coating is more durable.

04. Strong toughness:The galvanized layer forms a special metallurgical structure that can withstand mechanical damage during transportation and use.

05. Comprehensive protection:Every part of the plated parts can be galvanized, even in recesses, sharp corners and hidden places can be fully protected.

06. Save time and effort:The galvanizing process is faster than other coating methods.

02. Cheap:The cost of hot-dip galvanizing is lower than other coatings.

03. Reliable:The galvanized coating is metallurgically bonded to the steel, forming part of the steel's surface, so the coating is more durable.

04. Strong toughness:The galvanized layer forms a special metallurgical structure that can withstand mechanical damage during transportation and use.

05. Comprehensive protection:Every part of the plated parts can be galvanized, even in recesses, sharp corners and hidden places can be fully protected.

06. Save time and effort:The galvanizing process is faster than other coating methods.

Product Details

production line

VIEW MORE

YOU MAY LIKE