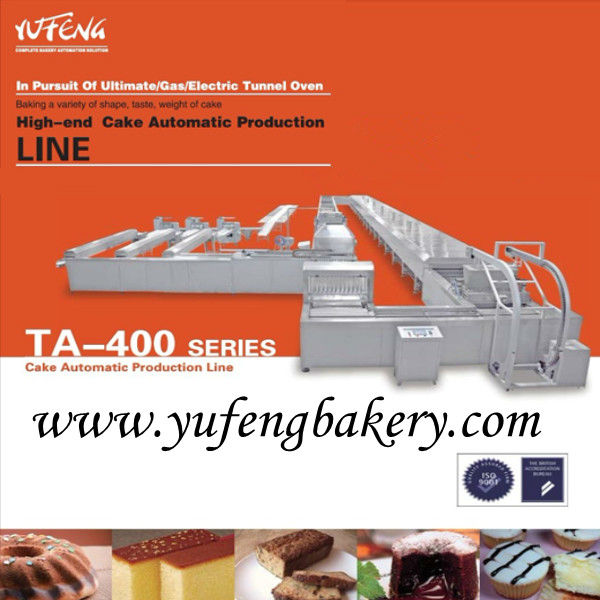

Factory direct selling brownie cup cake production line for industrial

- $1000.00 /set

- 1 set

- Shantou Yufeng Machinery Co., Ltd.

- Guangdong, China

- Mr William Liang

| Packaging Detail: | Outside Packaging is Standard Export Plywood, Inner Packaging is Stretch Film.; | Place of Origin: | Guangdong, China; |

| Voltage: | 3PH,380V,50Hz/3PH,220V,60Hz; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| oil spraying quantity(max): | 0.2-6g/time; | Power: | about 20kW; |

| Supply Ability: | 3 Sets per Month; | Application fields: | Snack food factory,Bakery; |

| Payment Terms: | L/C,T/T,Western Union; | dispensing speed: | 20times/min; |

| injecting quantity(max): | 2-20g/time; | dough depositing quantity: | 10-100g/time; |

| Brand Name: | YUFENG; | Certification: | CE Certificate; |

| injecting speed(max): | 2-20g/time; | oil spraying speed (max): | 20 times/min or 30 times/min; |

| depanning speed(max): | 4times/min(1-2trays/time),adjustable; | Port: | any port in China; |

| dough depositing speed(max): | 20times/min or 30 times/min; | Power Source: | Electric; |

| Warranty: | 1 year; |

Our TA series is to offer turnkey solution for producing cakes, such as bear cakes, cupcakes, Madeleine, custard cakes, ring cake with minimal manual input, optimum throughput and maximum output.

| Full Automatic Production Line | |||

ADVANTAGE

a- PLC Control;Touch Screen operate;

b- Full Automatic: Auto Depositor; Auto cream injecting; Auto Depanner;

c- Auto Cleaning system without disassembling. No manpower needed;

d- Stable working, not shaking like others;

e- High quality stainless steel as main framework;

f- Main electric equipment using world renowned brands

g- Large cake scope: (round cake, cartoon cake, custard cup, cup cake, muffin cake, choco coated cake, plum cake, etc)

h- Reasonable price, low cost high output, low rate of no-good products.

Cake: Muti-cake

Cake weight: 10g to 100g

Capacity: 150kgs to 2000kgs, over 2000kgs

A, The Bright Future of Custard Cake Making

Today, custard cake has become a popular food of rich nutrition all over the world. Because of people's higher living standard, faster working and living pace and the change of eating habit, the prospect of a thriving global market for custard cakes is expected to be realized.

At present, however, this production line made in foreign country is very expensive. In contrast, we, Shantou DAHE, based on the advantages of all similar production lines home and abroad and as the leading manufacturer of all the lines in China, has developed and produced the "Gas-style custard Cake Fully Automatic Production Line".

With capacity of 9,000kg per day, our product has the advantages of low cost, reasonable price, high level of automation, low rate of unqualified products and an easier way of cleaning.

B, The Feature Of The Production Line

1.The Gas-Channel Oven Type

Fan is used to mix air with gas in advance so as to attain effective gas-burning without polluting the oven. Temperature control-system consists of 10 sections, which are divided into upper and lower layer each of 5 sections. Thanks to the individual fire-tube, the cake out of this oven is much better than the one out of electrical-oven. Besides, the cakes are with more beautiful shapes, better taste and flavor, thus are more attractive to the customers.

2. Digital display is used in the Temperature Control Device of the Gas-Channel-Oven. The Auto-Temperature-Controller has 2-way-outlet with up & down limited, keep the gas fully-tube, even-temperature-heating and without any pollution. It is for cake, bread, puff, and Moon-Cake making.

3. Safer Device.

There are devices of No-Burn Safe-Guard Device and 2-Unit Electromagnetic Valve in the Burning System. It plays a role of double safeguard. With the PLC fire Inspection System, when there is no fire in the oven-head, the gas can be cut off in a short time.

4. The temperature of each section of the oven and the condition of each burning head can be seen on the Control Penal. In the first safeguard, the indicated light will be flashing when the fire extinguishes in the Burning-Tube. In the second one, the Fan will work to blow out the gas in the Oven.

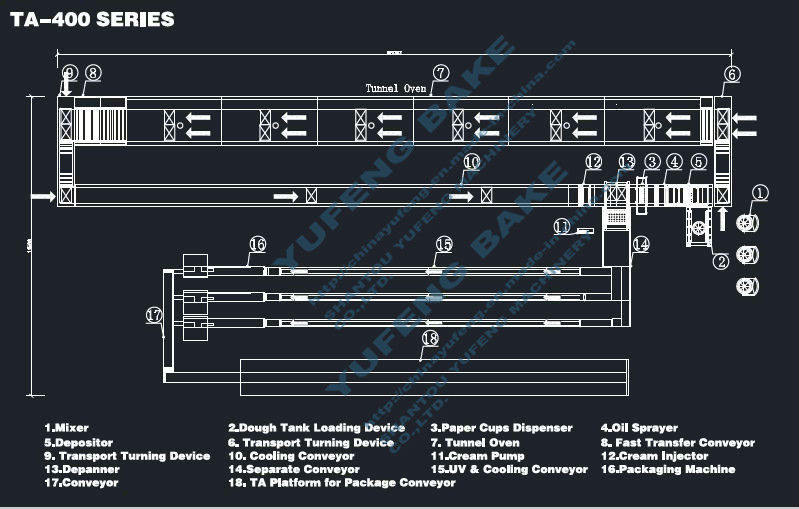

C, Processing Line

1. Mixing

2. Oil-Coating

3. Forming

4. Baking

5. Mould-Plate-Return

6. Cooling

7. Auto-Cream-injection

8. Cake-off-Mould

9. Separate conveyer

10. Packaging

Economic madeleine cake making machine developed by our company is applied to the production of food such as madeleine cakes which is semi-automatic model.

a- The machine first spray the oil onto the trays;

b- Then accurately fills a certain amount of paste into the moulds. Labor send the moulds to the rotary oven.

c- After baking, labor sends the moulds to fill cream into madeleine cakes that have been baked and thermoformed.

d- After cream/chocolate/jam filling, the trays enter the depanning section. Madeleine Cakes will be taken out from trays in one time accurately and completely, then the cakes are conveyed into the UV line for sterilization, while the empty trays move to oil sprayer for another circular production.

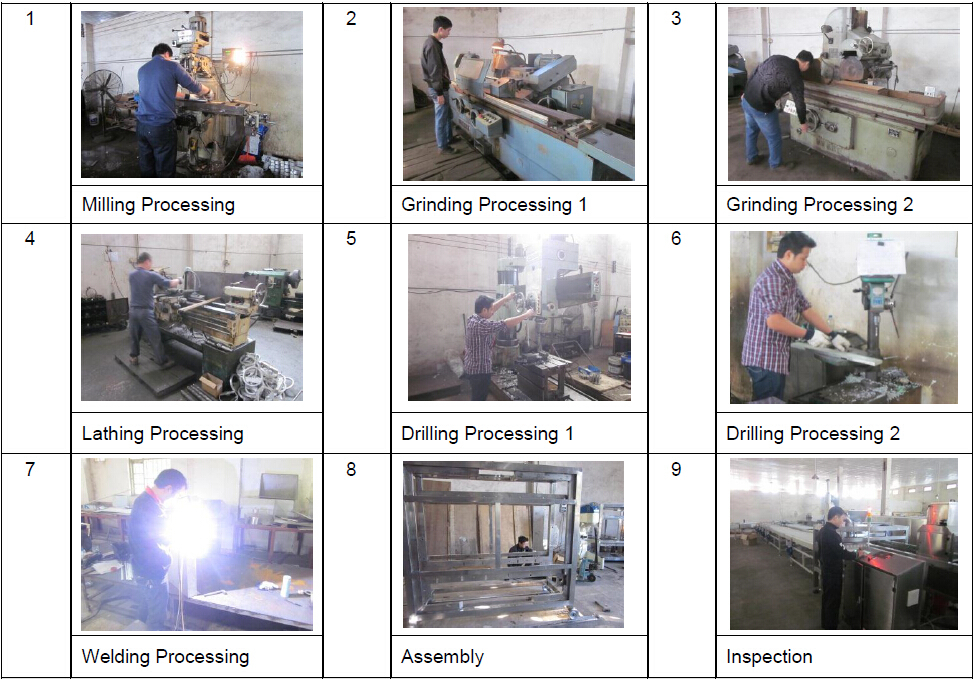

Shantou Yufeng Machinery Co., Ltd. is a leading manufacturer specializing in the research, design, production and distribution of all kinds of bakery equipments in China. We serve the world by providing high-quality, durable and cost effective food service equipments. Our products have good sales and reputation in domestic market, as well as Asia, the Middle East, Africa, Oceania and South America.

Meeting Room Laboratory

We had attented International Bakery Exhibition of China(Shanghai), Canton Fair, German IBA, Gulfood Manufacturing(Dubai), THAIFEX-WORLD OF FOOD in Asia(Thailand) and etc. Our company machine was popularity there and some customer place the order, sign the PI in the exhibition.

a- Welcome customization according to you demand.

b- Warranty: complete appliance one year, electric equipment only half a year, excluding quickwear parts.

c- Engineers available to service machinery overseas.

d- Video support: We will take any test video as clients need.

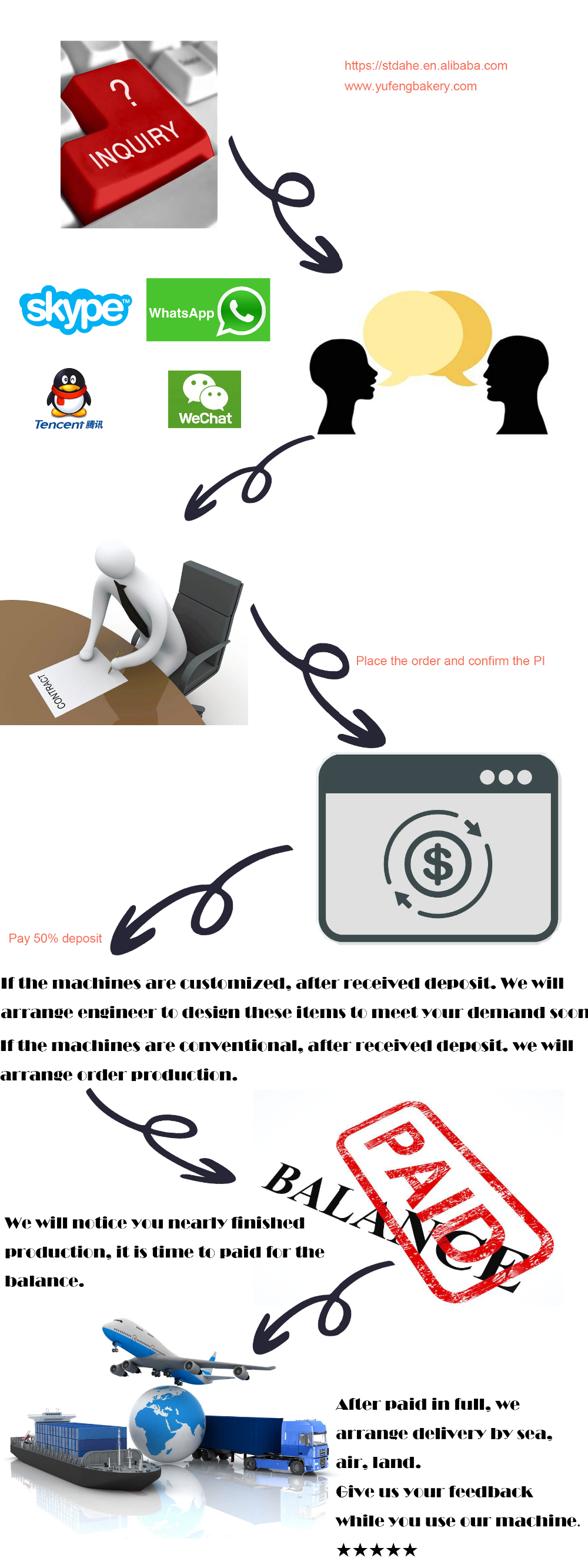

e- Payment Terms: T/T, L/C, Western Union(Parts only).

f- Shipment: By Sea/ Air/ Courier (FedEx, DHL etc.)

g- Welcome to visit our factory!

Q1. What is your terms of packing?

A: Outside Packaging is Standard Export Plywood, Inner Packaging is Stretch Film.

Q2. What is your terms of payment?

A: T/T 50% as deposit, and the balance before delivery. We'll show you the photos of the products before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, LC.

Q4. How about your delivery time?

A: Generally, it will take 20 to 35 working days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Is it support other languages?

A: Yes, there are English, French, Russian, German, Spanish, Hindi, Bengalese and so on.

Q6. What about your machine other main parts?

A: Most use international brand, quality assurance. eg: PLC use SIEMENS.

Q7. Could you give me any videos or pictures to have a further know more about your products?

A: 1.Yeah, please enter the site: www.yufengbakery.com OR https://www.youtube.com/channel/UC5UNvGVNkcV1fPuemTsSYqw

2.You could add our WeChat/WhatsApp/Skype. Please check "Contact Us"

Q8: How to place the order?

Q9: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Q10: May I visit your factory?

A: Sure, our office and factory are same place. We are warmly welcome your coming.ADD: NO.6 Nanlou Industrial District, Chaoshan Road, Shantou, Guangdong, China

Shantou Yufeng Machinery Co., Ltd.

ADD: NO.6 Nanlou Industrial District, Chaoshan Road, Shantou, Guangdong, China

Web: www.yufengbakery.com

Zoe Chung

Tel/WeChat/WhatsApp: +86 131 1254 7775

QQ: 1094889127

Skype: dahesales1