Fully automatic 5870pcs bath bomb per hour capacity bath bomb press machine with robotic arm

- $600.00 /set

- 1 set

- Ruian Furis Import & Export Co. Ltd

- Zhejiang, China

- Mr Harold Zhang

PRODUCT DETAIL

| Weight (tons): | 0.6 tons | Dimensions (L*W*H): | 1500*600*1900mm |

| Showroom location: | Canada, USA, Russia, Thailand, South Korea | Type of machine: | Hydraulic press, four-column two-beam hydraulic press |

| power supply: | 220V/380V/110, 1-phase, 3-phase can be customized | model: | Bath bomb press |

| place of origin; place of origin: | Zhejiang, China | Bath bomb size: | 20-100mm size bath bomb, can be customized |

| Packaging Details: | One wooden box, one machine | Core Components Warranty: | 1 year |

| Supply capacity: | 5 sets per month | Warranty: | 1 year |

| Recovery force (kN): | 100 kN | payment terms: | L/C,Western Union,D/P,D/A,T/T |

| Sliding stroke (mm): | 220 | Mechanical test report: | if |

| year: | 2022 | Video external inspection: | if |

| application: | For packaging bath bombs of different sizes and shapes | Applicable industries: | Hotels, Clothing Stores, Building Materials Stores, Manufacturing Plants, Machinery Repair Stores, Food and Beverage Plants, Farms, Restaurants, Home Use, Retail, Food Stores, Printing Stores, Construction Works, Energy and Mining, Food and Beverage Stores, Advertising Agencies |

| Core components: | Bearings, Motors, Pumps, Gears, PLCs, Pressure Vessels, Engines, Gearboxes | After-sales service provided: | Engineers can repair machinery overseas |

| product name: | bath bomb machine | Health status: | new |

| Certification: | CE ISO9001 | port: | Shanghai |

| brand: | Financial Reporting Standards | Marketing Type: | New Products 2021 |

| Voltage: | 220v, 380, 460v 1/3 phase, 220/380V | system: | normal |

| Motor power (kW): | 3.5kW | Main selling point: | automatic |

| Cooling Type: | air cooling | CNC or not: | normal |

Automatic powder feeding hopper, 80L large volume, stable and fast operation, can evenly feed powder into the mold

With stirring device, using wet powder will not jam the hopper

14 egg-shaped bath bombs in one click

Press 16 spherical bath bombs at one time

If the size of the bath bomb is small, it is easy to stick to the mold

We will add the rod to the center of the upper mold to make sure the tub bomb comes out of the mold easily

With a forklift-type robotic arm, the bath bomb can be automatically removed from the mold and placed on the conveyor belt

The spherical bath bomb will automatically run out of the robotic arm through the conveyor beltFriction, no damage to bath bombs

If the bath bomb is as per the logo and picture, we will use a grabbing robotic arm to take the bath bomb out of the mold and place it directly on the conveyor belt

Bath bombs according to the moon and stars

product description

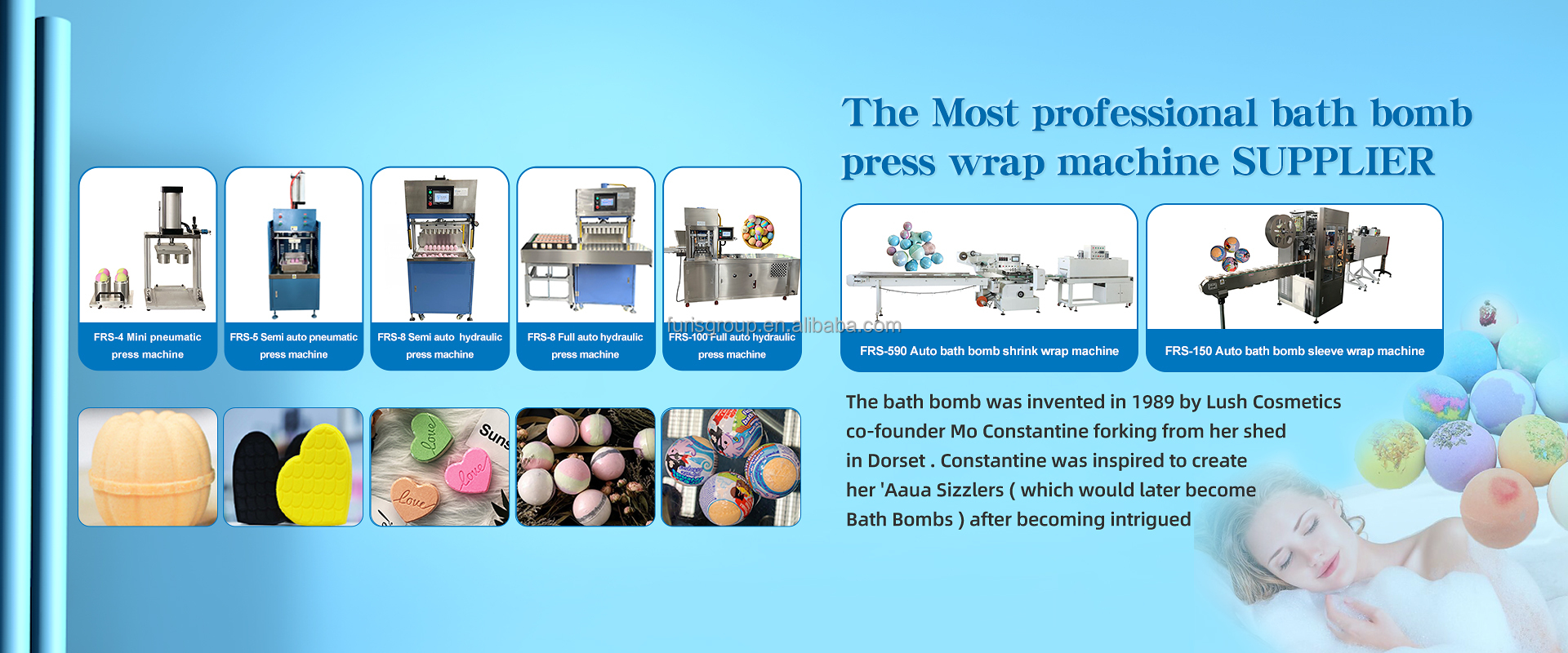

Furis Group can provide manual semi-automatic fully automatic bath bomb press and fully automatic bath bomb packing machine to meet inquiries of different capacities. Our machines are mainly exported to more than 20 countries such as the United States, Canada and Europe.

Features

compact size. Simple operation, convenient maintenance and multiple functions.

The machine pressure can reach 10T (the pressure can be customized), the pressure can be adjusted on the touch screen

This machine can realize multi-cavity molding, and the pressure remains unchanged, which greatly improves the production efficiency.

It adopts computer system to control PLC control and touch screen operation, which makes the machine operation very simple.

Can work in both automatic and manual models

Automatic stop function when hand is put into the mold

The cover is made of stainless steel and will not rust after long-term use.

The pressing time can be adjusted on the touch screen.

The imported hydraulic system is adopted to ensure stable operation and long service life of the machine.

The process is fully automatic, using a mechanical handle, which can automatically take out the bath bomb from the mold and put the bath bomb on the conveyor belt, which greatly saves labor

By changing the mold, the machine can press bath bombs of different shapes and sizes

The machine pressure can reach 10T (the pressure can be customized), the pressure can be adjusted on the touch screen

This machine can realize multi-cavity molding, and the pressure remains unchanged, which greatly improves the production efficiency.

It adopts computer system to control PLC control and touch screen operation, which makes the machine operation very simple.

Can work in both automatic and manual models

Automatic stop function when hand is put into the mold

The cover is made of stainless steel and will not rust after long-term use.

The pressing time can be adjusted on the touch screen.

The imported hydraulic system is adopted to ensure stable operation and long service life of the machine.

The process is fully automatic, using a mechanical handle, which can automatically take out the bath bomb from the mold and put the bath bomb on the conveyor belt, which greatly saves labor

By changing the mold, the machine can press bath bombs of different shapes and sizes

Additional feeders can be added to make two-color bath bombs automatic

The oil circuit of the machine is large

A rod can be added to the upper mold to ensure that the bath bomb will not stick to the upper mold and cannot be removed from the mold

Product parameters

Model | FRS-2 | FRS-4 | FRS-5 | FRS-8 | FRS-45 | Model | FRS-590 | FRS-150 |

Feeder volume | / | / | 10L | 20L | 20L | Maximum film size | <590mm | 15mm wide two layers |

greatest pressure | 250kg | 500KG | 5Ton (pressure customization) | 8Ton (pressure customization) | 45Ton (pressure can be customized) | Package dimensions | Length: 100mm-450mm Width: 10mm-200mm | Φ30-Φ150mm |

Maximum Pressure Bath Bomb Size | 8 cm | 8 cm | 15cm (customized) | 10cm (customized) | 20cm (customized) | Max Packed Bath Bomb | 8cm custom | 150mm customized |

capacity | 120 per hour | 240 per hour | 240 per hour (1.75" based on bath bomb size) | 1920 per hour (1.75" based on bath bomb size) | 1920 per hour (1.75" based on bath bomb size) | capacity | Max200pcs/min | Max 200/min |

strength | / | / | 2.5kW | 3kW | 5kW | strength | 20kW | 11kW |

Hydraulic oil | / | / | 46# | 46# | 46# | Film type | POF | PVC |

Air compressor | small | small | small | small | small | Air compressor | no need | no need |

cylinder volume | 50L | 100L | 100L | |||||

cooling method | air blow cooling | air blow cooling | air blow cooling | |||||

machine weight | 20kg | 25kg | 200kg | 800kg | 1500kg | machine weight | 1200kg | 1000kg |

Machine size | 40*10*50mm | 40*40*50mm | 700*650*1800mm | 1300*1650*1800mm | 1500*1000*1800mm | Machine size | 7500*1170*1500mm | 4000*1000*2000mm |

Bath bomb pleat packaging machine

Bath bomb shrink packaging machine

Bath bomb cover packing machine

customer photo

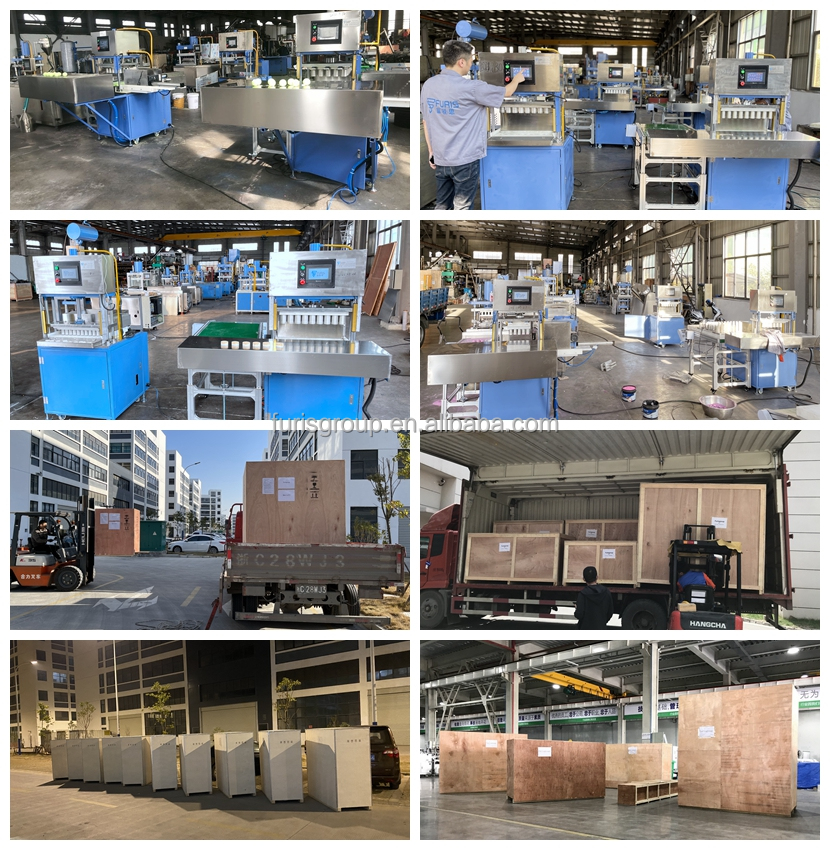

Company Profile

Furis I/E is a subsidiary of the furis group, specializing in import and export business. Furuis Group is an enterprise integrating R&D and sales of machinery. We are a professional manufacturer of pharmaceutical and cosmetic packaging machines and personal care products machines, etc. Our main products: blister packaging machine, capsule filling machine, tablet press, bath bomb press packaging line, washing powder pod machine, etc. We have more than 10,000 square meters of modern

Standard factory with 80 skilled workers. We organize production in strict accordance with ISO9001:2002 quality management system, and the machines have obtained CE certification. Advanced equipment, superb manufacturing technology and perfect testing system ensure product quality and precision. With complete production equipment, stable quality, reliable performance and good after-sales service.

Standard factory with 80 skilled workers. We organize production in strict accordance with ISO9001:2002 quality management system, and the machines have obtained CE certification. Advanced equipment, superb manufacturing technology and perfect testing system ensure product quality and precision. With complete production equipment, stable quality, reliable performance and good after-sales service.

Certification

FAQ

Q: Why can't a bath bomb be well formed with your machine?

A: Most new customers do not know that citric acid powder is needed to make bath bombs. They buy citric acid granules from the market without grinding them into powder.

A: We have our own factory to manufacture pharmaceutical machines and packaging machines, and we provide perfect OEM and after-sales service.

Q: Can you send me the video to see how the machine works?

A: Of course, we have made videos for each machine and uploaded to Youtube.

Q: How do I know your machine is working well?

A: Before delivery, we will test the working condition of the machine for you. Before the machine is shipped, we will let the machine run for a week in our factory.

Q: How do I know your machine is designed for my product?

A: You can send us a sample of your product and we will test it on the machine.

Q: How do I know your machine is designed for my product?

A: You can send us a sample of your product and we will test it on the machine.

Q: How do I pay for my order?

A: We accept payment by T/T, Western Union, Alibaba Trade Assurance. Pay 30% deposit after finishing the machine, you can pay the balance before shipping.

Q: Do you have CE certificate?

A: Each machine has CE certificate.

Q: How is the quality of your machine?

More than 15 years of manufacturing experience, experienced engineers and good CNC machine tools make the machine stable

Performance and high quality, excellent quality and competitive price make our machines well received by customers, now

Our machines are mainly exported to North America and Western Europe.

Q: How about the machine warranty and after-sales service?

One year warranty, within one year, if the spare part is broken, we can send new spare parts for free, but the customer needs to pay the express fee.

Q: How is the after-sales service?

We have several technicians with passports ready to travel around the world to serve you. There is a 24-hour technical support hotline. We have an 18-hour Internet hotline for technical support. Workshop cameras to help you adjust and troubleshoot machines in working situations. We have many agents around the world who can provide technical support locally.

Our advantage

1. High quality + economical solution

Furis Group and Chinese technical support match your high quality requirements.

Furis Group's economical prices give you better budget control.

Furuis Group's strict quality control, ISO 9001 certification, CE certification and other qualifications can ensure that you avoid any risks in machine selection or project implementation.

2. Professional turnkey project

Furis Group GMP experts and validation engineers can guide your projects and documents to WHO GMP.EU GMP USA etc.

FRS plant master planning experts can ensure not only quality in every aspect of your project, but also cost-effective flexibility and scalability and safety.

Furis Group's professional design and experienced engineering team can support your project to optimize implementation, saving labor time and cost.

3. One-stop technical service

Furis Group and global partners can provide you with the latest technology and knowledge for the validation and production of machine projects.

FRS electromechanical engineers can make customized designs according to the user's requirements.

And manufactured according to European standards.

HM Energetic and professional team can effectively provide you with one-stop technical service from sample test to test

FAT, installation and commissioning, SAT, documentation and validation training.

VIEW MORE

YOU MAY LIKE