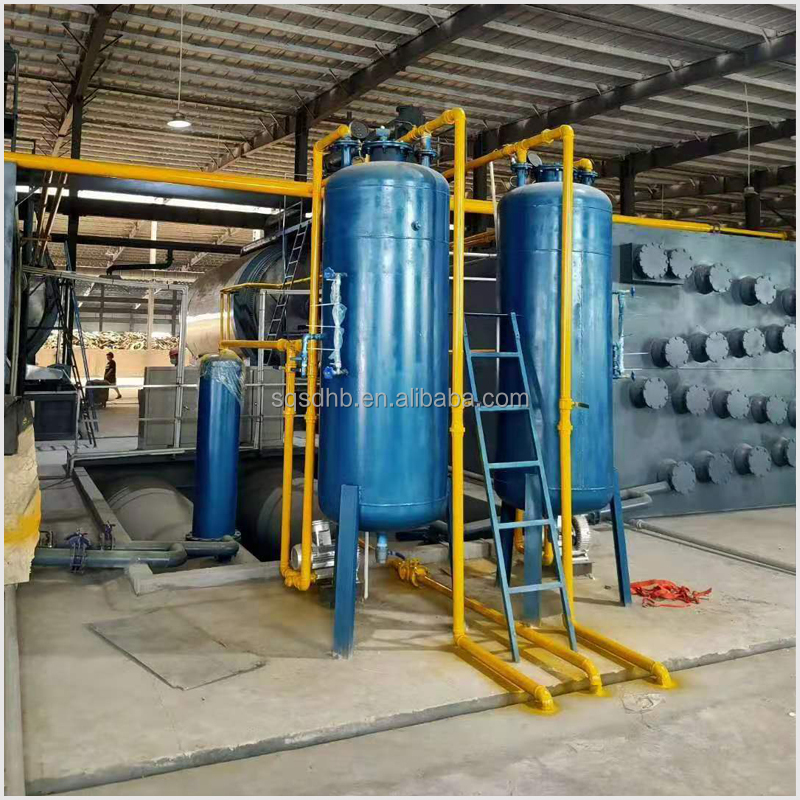

Fully continuous pyrolysis machine 20 tons of plastic waste in fuel oil processing plant

- $10000.00 /set

- 1 set

- Shangqiu Seden Environmental Equipment Co., Ltd

- Henan, China

- Ms Aimee Jin

PRODUCT DETAIL

| cooling system: | water cooling | State of health: | new |

| Heating fuel: | Fuel & Exhaust Gas/Electric Heating | Video shipment inspection: | if |

| Equipment capacity: | 10kg- 2 tons/hour | Warranty: | 1 year |

| place of origin; place of origin: | Henan, China | Reactor thickness: | 16MM/18MM |

| Showroom location: | Germany, Russia, Romania | Marketing Type: | New Products 2020 |

| Supply capacity: | 300 sets per year | Mechanical test report: | if |

| Model: | 2800*8000 | Applicable industries: | Manufacturing plants, energy and mining, other |

| Core components: | PLC, engine, bearing, gearbox, motor, gear, water pump | payment terms: | L/C, T/T |

| brand: | Seddon | Machine name: | Waste tire pyrolysis plant pyrolysis machine |

| Packaging Details: | It depends on machine size: usually 1*20GP or two 40HQ / one 40HC or one 20GP* one 40FR and one 40HQ | strength: | 13KW-130KW |

| Core component warranty: | 1 year | Main selling points: | automatic |

| Weight (kg): | 40000 kg | port: | Lianyungang/Qingdao |

| Package preview: | Final product: | Fuel Oil & Carbon Black & Wire & Exhaust Gas | |

| Steel: | Q345R&SS316L/304SS | Raw materials: | Waste tires & waste plastics & sludge & heavy oil |

Product Description

Our company is committed to the design and manufacture of fully continuous pyrolysis equipment/manual (batch) model pyrolysis equipment/batch model transformation into fully continuous pyrolysis equipment.

| thing | Continuous pyrolysis equipment | ||

| Model | SD-1200 | SD-1800 | SD-2200 |

| capacity | 1 metric ton/hour | 1.5 metric tons/hour | 2 metric tons/hour |

| strength | 65 kW | 90kw | 130kw |

| job type | continuously | ||

| Reactor type | Multiple reactors (depending on raw material) | ||

| turn around | chain drive | ||

| cooling system | Water cooling/antifreeze | ||

| Reactor material | Q245R/Q345R/CRMOV/304SS/310SS/316SS | ||

| way to heat up | Electric heating/oil/gas heating | ||

| raw material | Waste plastic/rubber/tyre/aluminum/oil sludge | ||

| output | |||

| thing | Manual (batch) model pyrolysis unit | |

| Specification | SD-2200*6000 | |

| SD-2200*6600 | ||

| SD-2600*6600 | ||

| SD-2800*6000 | ||

| SD-2800*6600 | ||

| SD 2800*8000 | ||

| raw material | Q245R/Q345R/CRMOV/304SS/316SS/310SS | |

| Steel Thickness | 14MM/16MM/18MM/20MM | |

| strength | 18KW-35KW | |

| Floor area | 300-400 square meters | |

| Worker | 3-4 people | |

| loading method | Hydraulic feeder | |

| way to heat up | Fuel/gas/electric heating method | |

Final products after pyrolysis:

| raw material | Final product | |||

| Waste rubber/tire | Fuel 40%-45% | Carbohydrates 30%-40% | 10%-15% steel | 10%-15% gas |

| waste plastic | Fuel oil 20%-80% | Carbon coke 40%-50% | 10%-15% steel | 10%-15% gas |

| Fuel oil: can be sold to ceramic factories, glass factories, brick factories for burning as energy | ||||

| Carbon coke: can be used in industrial carbon coke N550, N330, or as additives for shoe materials and shoe covers | ||||

| Steel: Recyclable for use in steel mills | ||||

| Gas: It can be recycled by the machine itself for energy saving or compressed and stored by our gas compression system. | ||||

About us Company introduction

Certifications of our company: ISO, CE, SGS, TUV.

VIEW MORE

YOU MAY LIKE