High Quality Custom 37 ACN Content Powder 80 Mooney 50 Mesh Nitrile/Nitrile Rubber Products Ready Stock SC-830G

- $2.50 /kilogram

- 1 kilogram

- Hengshui Jiansheng Rubber & Plastic Technology Co., Ltd.

- Hebei, China

- Ms Kathy huang

PRODUCT DETAIL

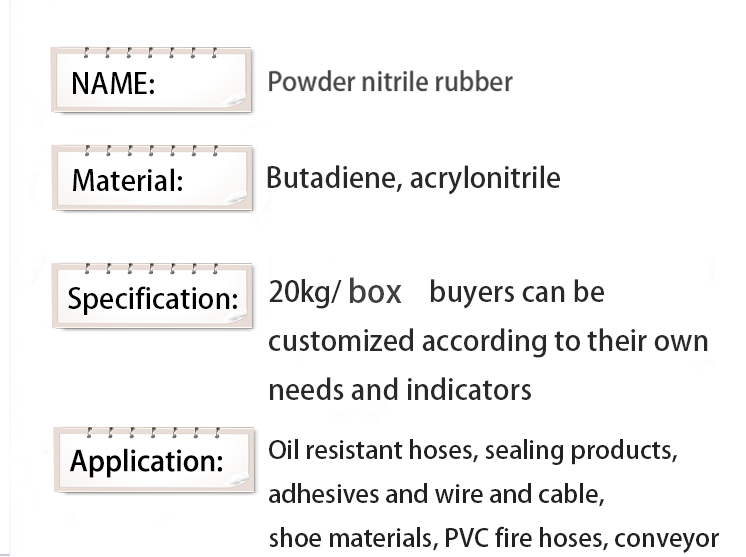

| product name: | powdered nitrile rubber | Mooney viscosity (ML1+4,100): | 80±10 |

| network: | 50 mesh screening rate ≥ 98% | appearance: | powder |

| Package preview: | model: | SC-830G | |

| brand: | Healthy | Package: | 25kg/box |

| Advantage: | Excellent oil resistance and high temperature resistance | application: | Suitable for PVC conveyor belts, PVC hoses, wires and cables, etc. |

| sample: | free | Acetonitrile content %: | 37±2 |

| color: | white | place of origin; place of origin: | Hebei china |

| payment terms: | wire transfer |

Product Description

Product Description:

Powdered nitrile rubber is a copolymer of butadiene and acrylonitrile polymerized at low temperature, and it is a powdered elastomer made by a special process. Raw rubber is available in block, emulsion, granule and powder form. The particle size of powdered nitrile rubber is generally 0.3-0.6mm, with good fluidity and basic properties of rubber. In terms of reprocessing, compared with block rubber, the cutting process is omitted, and dry mixing of powder can be realized. In addition, no preheating is required for processing, good dispersion and short mixing times. It can also be mixed directly with compounding ingredients for extrusion or injection molding, saving energy during processing and reducing heat build-up to reduce scorch. The product does not agglomerate during shipping.

This product is a customized product, you can consult customer service before purchasing, and the final price is subject to processing and customization claims!

Product parameters

Model | Acetonitrile content % | Mooney viscosity ML(1+4)100℃ | network | application |

SC-830G | 37±2 | 80±10 | 50 mesh screening rate ≥ 98% | Good oil resistance and high temperature resistance, suitable for PVC conveyor belts, PVC hoses, wires and cables, PVC seals strip etc. |

Product advantages

Our selling point

1. Reduce plasticizer migration. 2. Improved heat resistance. 3. Improved oil resistance. 4. Improved bending resistance and cold resistance. 5. Improve wear resistance. 6. Reduce compression set 7. Reduce extrusion expansion rate, make melt more stable and improve dimensional stability. 8. Rigid PVC has obvious toughening effect and improves impact strength.

application

Applications:

Widely used in rubber product processing and application, performance improvement, and resin modification (such as toughening, wear-resistant, and oil-resistant modification of resins such as PVC, PF, EP, SAN, and EVA). It can be used in the production of oil-resistant rubber hoses, doors and windows, sealing strips, sealing products, adhesives and wires and cables, shoe materials, microporous sponge soles, automotive dashboards, safety shields, PVC fire hoses, conveyor belts (PVC, PVG) and other products.

Other product parameters

Model | Acetonitrile content % | Viscosity Pa·S·40℃ | network | application |

SC-830E | 30±2 | 75±10 | 50 mesh screening rate ≥ 98% | Special modified material for PVC resin, suitable for PVC conveyor belt, PVC hose, wire and cable, PVC sealing strip, etc. |

SC-830G | 37±2 | 80±10 | 50 mesh screening rate ≥ 98% | Good oil resistance and high temperature resistance, suitable for PVC conveyor belts, PVC hoses, wires and cables, PVC seals strip etc. |

SC-830D | 19±2 | 65±10 | 50 mesh screening rate ≥ 98% | Good low temperature resistance, suitable for PVC shoe materials, pipes, plates, PVC floors, door and window sealing strips, Refrigerator sealing strip, phenolic resin modification, etc. |

VIEW MORE

YOU MAY LIKE

Other Products

-

China Hebei Hengshui Rubber Factory customized NBR/NBR+PVC poly blend. For rubber roller industry$1.80 / kilogram

China Hebei Hengshui Rubber Factory customized NBR/NBR+PVC poly blend. For rubber roller industry$1.80 / kilogram -

Nitrile rubber raw material for rubber hose and rubber roller nbr nbr/pvc NV3375$3.40 / kilogram

Nitrile rubber raw material for rubber hose and rubber roller nbr nbr/pvc NV3375$3.40 / kilogram -

High quality, environmentally friendly L NBR/ nitrile butadiene liquid rubber| LNBR820 (EP)$3.70 / kilogram

High quality, environmentally friendly L NBR/ nitrile butadiene liquid rubber| LNBR820 (EP)$3.70 / kilogram