High Torque Magnetic Powder Clutch Dual Shaft Powder Clutch For Cutting Machine DC 24v From12 To 400 Nm

- $50.00 /piece

- 1 piece

- Dongguan Taiji Speed Reducer Clutch Co., Ltd.

- Guangdong, China

- Ms dgtaiji Sandra

| length: | 191.7mm-500.4mm | Marketing Type: | Hot Products of 2022 |

| weight: | 5.2kg-100kg | Voltage: | DC 24v |

| Rated torque: | from 12 to 400 Nm | port: | Shenzhen/Guangzhou/Shanghai/Hong Kong |

| Video shipment inspection: | if | color: | silver |

| Mechanical test report: | if | Maximum speed: | 1800 rpm |

| place of origin; place of origin: | Guangdong, China | brand: | Tian Ji |

| Types of: | Two-axis magnetic powder clutch | Packaging Details: | Wooden case or according to customer's requirement. |

| Applicable industries: | Hotels, manufacturing plants, machine repair shops, food and beverage plants, retail, printing plants, energy and mining industries, various | State of health: | new |

| Supply capacity: | 10000 pieces per month or according to customized requirements. | current: | 0.94A-3.5A |

| payment terms: | Western Union, T/T, MoneyGram, PayPal | Warranty: | 1.5 years |

| Weight (kg): | 8 | model: | TJ-POC |

| strength: | 250w-2800w | high: | 152mm-395mm |

| Showroom location: | United States |

High torque magnetic powder clutch for cutting machine

| Product Details |

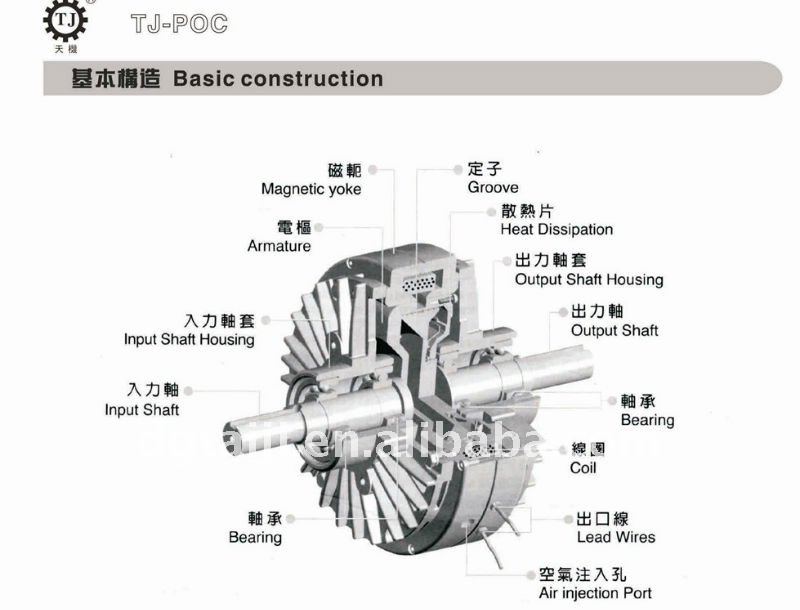

Brief introduction of magnetic powder clutch:

Magnetic clutch for tension control, overload protection, torque load, etc. Such as printing, paper machine, rewinding machine, wire drawing machine, metal rolling mill, film processing machine, textile machinery, etc.; also such as motor, engine, hydraulic reducer and other loading devices for loading experiments.

Magnetic clutches are based on electromagnetic theory and use magnetic force to transmit torque. It has a linear relationship between excitation current and torque transmission. It transmits a certain torque without any slip, and has the advantages of fast response, simple structure, no pollution, no noise, no impact vibration and energy saving. It is an automatic control element with a wide range of uses and superior performance. Magnetic clutches are widely used in buffer start, overload protection, speed regulation, winding system, winding tension control, etc.

Magnetic powder clutch application:

Printing machinery, papermaking machinery, bag making machinery, papermaking machinery, wire and cable machinery, coil machinery, wire machinery, binding bag machinery, textile machinery, weaving machinery, woodworking machinery, testing equipment, simulated load use, precision tension control of various machinery , general industrial equipment, other general industrial machinery.

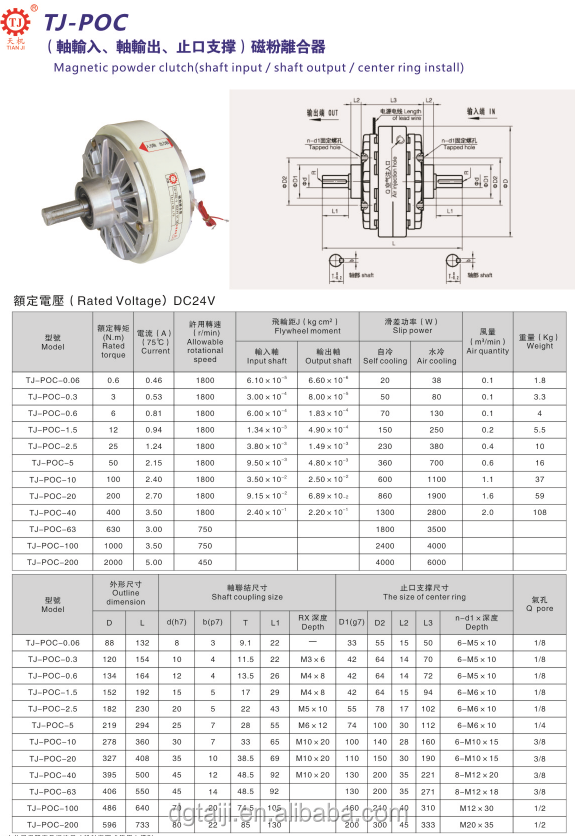

Magnetic powder clutch parameters:

| Model | TJ-POC-1.5 | TJ-POC-2.5 | TJ-POC-5 | TJ-POC-10 | TJ-POC-20 | TJ-POC-40 |

| torque | 12 Nm | 25 Nm | 50 Nm | 100 Nm | 200 Nm | 400 Nm |

| current | 0.94A | 1.24A | 2.15A | 2.4A | 2.7A | 3.5A |

| weight | 5.2KG | 9KG | 14.5KG | 37KG | 53KG | 100KG |

| Maximum speed | 1800 rpm | 1800 rpm | 1800 rpm | 1800 rpm | 1800 rpm | 1800 rpm |

| powder weight | 20 grams | 33 grams | 60 grams | 140 grams | 225 grams | 370 grams |

Magnetic powder clutch details:

Application of magnetic powder clutch:

Magnetic clutch DC power excitation. During the transportation of the magnetic clutch, the magnetic powder will accumulate somewhere when it is often used, and sometimes it will even appear "stuck". Just turn the clutch 180 degrees all the way, and tap it several times with a wooden hammer to make the loose powder fall off. Or turn the lever around its axis, as long as you turn it immediately after turning it. It is recommended to use a loose fit for the connecting part with the coupling. Non-axial runout. Before use, run-in should be carried out, run at 20% of the rated current for a few seconds, then turn off the power, and repeat several times. 500N.m bigger clutch. Another part of the magnetic mount. During the running-in process, the magnetic powder is filled from the top, under the barrier, the excitation current gradually turns to the side.

If the magnetic clutch is not used for a long time, it should be stored in a dry place, and the product should be stored for more than one year. It is recommended to maintain it comprehensively before use.

Magnetic powder clutch features:

(1) High precision torque control

The torque control range is very wide, the control precision is high, and the torque and the excitation current are transmitted in the correct ratio to achieve high-precision control.

(2) Superior durability, long life

Using heat-resistant, wear-resistant, anti-oxidation, anti-corrosion super super alloy powder, long life.

(3) Fixed superior stability torque characteristics

The magnetic properties of the magnet are good, the binding force with the mud is stable, the sliding torque is very stable, and has nothing to do with the relative speed, and the constant torque can be sustained.

(4) Use of sliding continuous operation

Good cooling effect and uniform thermal deformation cooling structure, coupled with high heat-resistant powder, make the sliding link and braking power large, and can slide smoothly without causing vibration.

(5) Links are smooth and impact-free

There is minimal to no impact on the link for smooth starts and stops. And the resistance torque is extremely small, so no unnecessary heat will be generated.

(6) Suitable for high frequency operation

Quick response and special cooling structure, suitable for high-frequency operation.

(7) Light weight, maintenance-free, long life

Simple and lightweight, high temperature resistant coils and special grease bearings are used to resist the wear and tear of the armature that is prone to wear and prolong the service life.

Package: