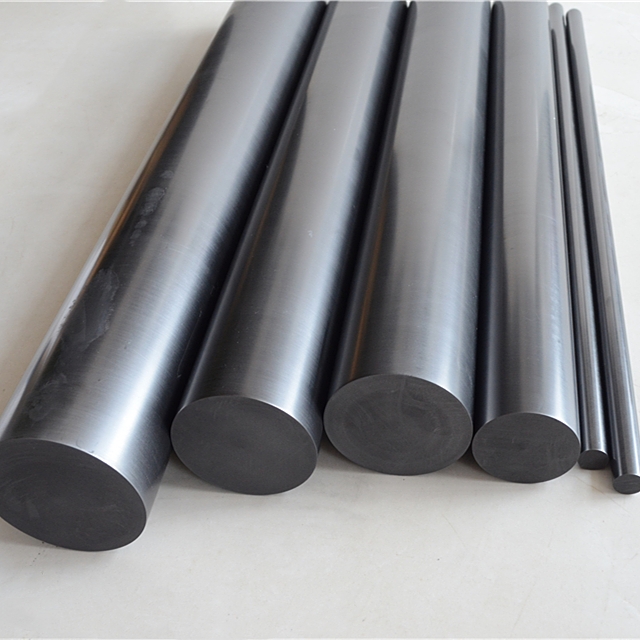

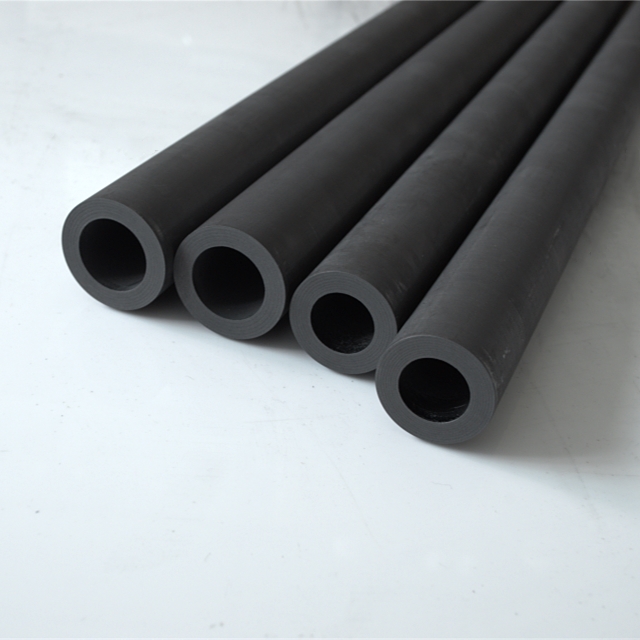

High-purity high-strength graphite rod

- $0.10 /piece

- 1 piece

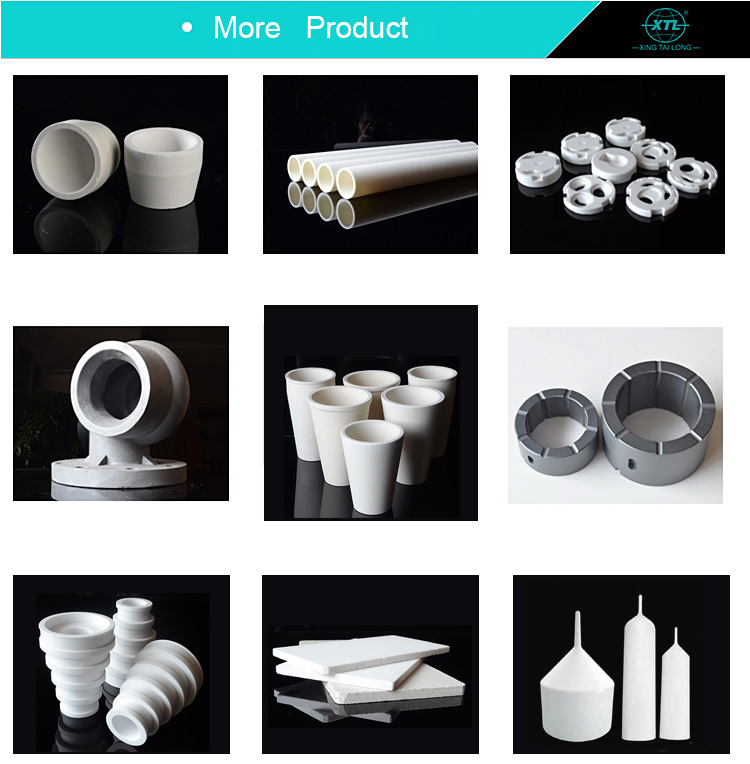

- Liling Xing Tai Long Special Ceramic Co., Ltd.

- Hunan, China

- Ms Anna Peng

| Attributes: | Oxidation resistance, high temperature resistance, low resistivity | application: | Smelting, industrial use, industrial furnace |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Supply capacity: | 40000 pieces per month |

| Grain Size: | 0.8~4.0mm | Compressive strength: | 65-135Mpa |

| Revolt: | 8-15Ω | type: | Isostatic graphite rod |

| surface: | grinding, polishing | product name: | High-purity and high-strength graphite rod |

| density: | 1.58~1.92g/cm3 | brand: | Xingtailong,OEM |

| port: | Shenzhen, Shanghai, Guangzhou, Qingdao | Resistance (μΩ.m): | 6.0-9.0μΩm |

| Key words: | graphite rod | Packaging Details: | 1. Individually packaged. 2. Carton with bubble bag. 3. Wooden box. 4. According to customer's request. |

| Porosity(%): | 13~14μm | Bulk density (g/cm3): | 1.65-1.90 g/cubic centimeter |

| feature: | High strength, corrosion resistance, good thermal shock resistance | model: | XTL, custom |

| Origin: | Hunan, China | length: | custom made |

| color: | black gray |

High-purity and high-strength graphite rod

advantage:

1. Fine lines

2. High density

3. High quality

4. Homogeneous structure

5. High mechanical strength

6. Excellent thermal conductivity

7. Proper electrical conductivity

8. Minimum wettability to molten metal

9. Hard surface, good flexural strength

10. Resistant to chemical attack and thermal shock.

| Bending strength | 65MP |

| Compressive strength | 210MPa |

| Bulk density | 1.75 g/cm3 |

| Shore hardness | 85 |

| porosity | 3.0 |

| temperature | 500℃ |

| Material | Graphite Immersion Antimony |

application:

1. Electrodes, anodes, cathodes, resistors, stirring rods, special structural parts, etc.

2. Metallurgy, mechanical engineering,

3. Chemical industry, electrochemistry, glass ceramics and other industries.

Industrial ceramic properties

|

thing |

density |

Porosity% |

Compressive strength |

Breaking strength |

Resistivity |

Ash content |

micron particles |

|

g/cubic centimeter |

MPa |

MPa |

Micron |

% |

|||

|

≥ |

≥ |

≥ |

≤ |

≤ |

|||

|

1 |

1.7 |

15 |

40 |

20 |

10 |

0.01 |

8 |

|

2 |

1.75 |

15 |

55 |

27 |

10 |

0.01 |

8 |

|

3 |

1.77 |

15 |

58 |

28 |

10 |

0.01 |

8 |

|

4 |

1.8 |

15 |

65 |

30 |

10 |

0.01 |

8 |

|

5 |

1.82 |

15 |

68 |

33 |

10 |

0.01 |

8 |

|

6 |

1.85 |

15 |

78 |

40 |

10 |

0.01 |

8 |

|

7 |

1.88 |

13 |

82 |

42 |

10 |

0.01 |

8 |

|

8 |

1.9 |

13 |

84 |

44 |

10 |

0.01 |

8 |