Hot selling energy-saving pool aeration pump ring blower for fish farming circulating aquaculture system

- $139.99 / 1 - 4 pieces

$129.99 / 5 - 9 pieces

$122.99 / 10 - 19 pieces

$116.99 / >=20 pieces - 1 piece

- Dongguan Foersheng Intelligent M&E Co., Ltd.

- Guangdong, China

- Mr Blower

PRODUCT DETAIL

| payment terms: | L/C, Western Union, T/T, MoneyGram | Warranty: | 24 months |

| Energy source: | electric blower | greatest pressure: | 160 mbar |

| Origin: | Guangdong, China | Maximum Vacuum: | -150 mbar |

| Material: | aluminum alloy | application: | hair dryer |

| Supply capacity: | 5000 pieces per month | pressure: | high pressure |

| port: | Shenzhen/Guangzhou | Package preview: | |

| product name: | Fish Pond Aeration Pump | Customization support: | OEM production |

| Motor material: | 100% pure copper | frequency: | 50/60 Hz |

| color: | silver or gold | Rated voltage: | 200-240V |

| brand: | Gurui | Packaging Details: | 1. Packed in individual cartons. 2. The carton will be wrapped on the pallet with plastic wrap. 3. Special design and customization are available as required. Delivery details: Standard stock: 10 working days; Special production: 15~25 days. |

| usage: | ventilation | Maximum Airflow: | 145 cubic meters / hour |

| Blower Features: | 100% oil-free | model: | GHBH 1D2 12 1R4 |

Product Description

product style | Single stage single phase aeration ring blower | ||||||

model | GHBH 1D2 12 1R4 | weight | 15 kg | ||||

degree of protection | IP55 | insulation level | f | ||||

Certificate | CE certificate, RoHS certificate, ISO certificate, TUV certificate | ||||||

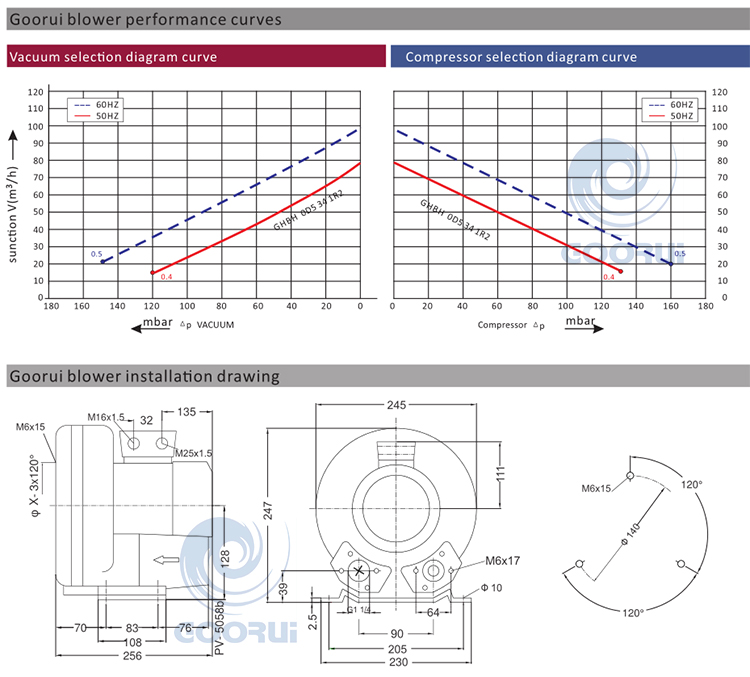

frequency | 50 Hz | 60 Hz | |||||

rated power | 0.8kW | 0.9 kW | |||||

Rated voltage | 200-240(volts) | 220-275 (volts) | |||||

rated current | 5.2 (A) | 5.8 (A) | |||||

Maximum air volume | 145 cubic meters / hour | 175 cubic meters / hour | |||||

vacuum | -150 mbar | -160 mbar | |||||

greatest pressure | 160 mbar | 140 mbar | |||||

sound level | 63db(A) | 64db(A) | |||||

feature

Efficient motor;

Built-in thermal protector (PTC);

High temperature resistant bearings;

Provide special customized blower and OEM;

24-month warranty and long-term technical support;

Passed CCC, CE, SGS, TUV, RoHS, ISO9001 certification.

IP55 & insulation class H;

Built-in thermal protector (PTC);

High temperature resistant bearings;

Provide special customized blower and OEM;

24-month warranty and long-term technical support;

Passed CCC, CE, SGS, TUV, RoHS, ISO9001 certification.

ElectivehangarorAppearance model

silver

Golden

GOORUI side channel blower ismaintenance free:External permanently lubricated bearings Non-contact rotating impeller Fan cooled motorGOORUI side channel blower isuser friendly:Weight-optimized design through aluminum die-casting Possibility of vertical or horizontal installation Suitable for converter operationGOORUI side channel blower isenvironmentally friendly:·Oil-free operation ·Low energy consumption ·Low noise emissionGOORUI side channel blowercan be used worldwide:Iso F class motor with 50/60Hz voltage range Protection type IP55 with integrated thermal protection switch (standard) CE, TUV, RoHS, CCC and ISO9001 certifiedouradvantage:· Wide range of size options · Wide range of accessories · 100% inspection before delivery · Spare parts in stock · Service at our facility or on site · Fast and reliable delivery

The above data is based on laboratory tests. The actual application will have a deviation of ±10% due to factors such as altitude, air density, humidity, and temperature!

GOORUI side channel blowerapplicationfor aquaculture

EvisceratedFish and molluscs must be gutted and cleaned before any further processing. The bench is equipped with a suitable vacuum nozzle to extract the viscera from the fish. A central vacuum system then passes the mixture of liquid and coarse particles through filters to separate them for proper disposal.feed the fish

Fish food distribution is arranged by a pneumatic system of pressure from a barge or boat to the fish in open water (aquaculture cages).fish treatmentVacuums live fish mixed with seawater from fishing boats, culture or buffer tanks to processing plants, from rearing cages to graders. Vacuum pumps are also used in pressure mode to transfer live fish from storage containers to the point of slaughter.Fish pond oxygenationUsing a rotary blade blower can significantly increase the oxygen content of the water, thereby increasing the number of fish that can be kept in the pond. During this process, air is drawn from the atmosphere and enters the tube diffuser through the inlet. It then diffuses into the water through tiny openings and rises in tiny bubbles. Oxygen in the water allows the fish to grow and reproduce faster, significantly increasing production.PackageAir and the oxygen it contains has a detrimental effect on the quality and shelf life of fresh food. For this reason, many processes require evacuation. A classic vacuum application in this field is vacuum packaging. A central vacuum system pulls the air out of the package before sealing it. Suction groups are used in packaging machines for many industrial purposes.

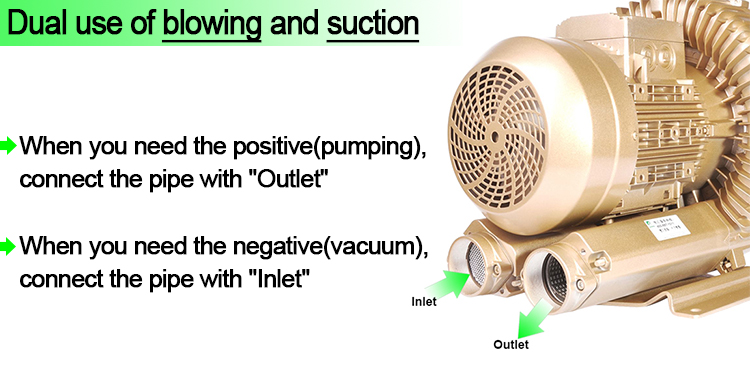

instruct1. It should be placed in a relatively stable place, and the surrounding environment should be clean, dry and ventilated. 2. The direction of rotation of the impeller must be consistent with the pointed direction marked on the fan cover. 3. When working, the working pressure should not be greater than 8kPa, so as not to overheat the air pump and damage the air pump due to overcurrent of the motor. 4. It is strictly forbidden for solids, liquids and corrosive gases to enter the pump body. 5. The filters and mufflers at both ends of the air inlet and outlet should be cleaned in time according to the situation, so as not to be blocked and affect the use. 6. The outer connection of the air inlet and outlet must be connected with a hose (rubber tube, plastic spring tube).Precautions

1.Flat and spring washers must be used to tighten the screws.2.It is best to use rubber buffer rubber to bear the weight of the air pump, especially for high-power air pumps, it is indispensable.3.For some occasions that require noise, a muffler can be installed to reduce the noise (usually to about 5 decibels), and the muffler is installed at the end of the air inlet or outlet pipe.4.For some occasions with high noise requirements, a layer of sound-absorbing cotton can be added according to the situation of the machine itself to meet the noise requirements of the site. Please consult our customer service for details.5.When using sound-absorbing cotton to silence the noise, pay attention to the distance between the air pump and the box, pay attention to the ventilation and heat dissipation of the air pump, and pay attention to the use of rubber pads to bear the weight of the air pump. Consult customer service according to the pictures.6.The air inlet and outlet of the air pump are connected by pipes and should be connected by hoses to isolate vibration.

VIEW MORE

YOU MAY LIKE