LMS kitchen cabinet drawer slide roll forming machine

- $160000.00 / >=150000 sets

- 150000 sets

- Guangzhou Lms Machinery Co., Ltd.

- Guangdong, China

- Mr Yongdong Zhu

PRODUCT DETAIL

| Weight (kg): | 5000 kg | Marketing Type: | 2019 Hot Products |

| Core components: | PLC, engine | place of origin; place of origin: | Guangdong, China |

| Model: | 45# | State of health: | new |

| Showroom location: | not any | application: | metal workpiece |

| color: | standard | payment terms: | wire transfer |

| weight: | 5000 kg | Mechanical test report: | if |

| Control System: | PLC automation | Warranty: | 1 year |

| After-sales service provided: | Engineers available to service machinery overseas | port: | Guangzhou, China |

| Material: | Carbon steel, stainless steel, silicon, galvanized | Main selling points: | automatic |

| Supply capacity: | 10 sets per month | length: | 10 m |

| Packaging Details: | bare bag | usage: | 10 years |

| Core component warranty: | 1 year | Video shipment inspection: | if |

| strength: | 380V 50Hz | Voltage: | 380V,50HZ |

| brand: | learning management system | Applicable industries: | Building material stores, manufacturing plants, construction projects |

LMS kitchen cabinet drawer slide roll forming machine

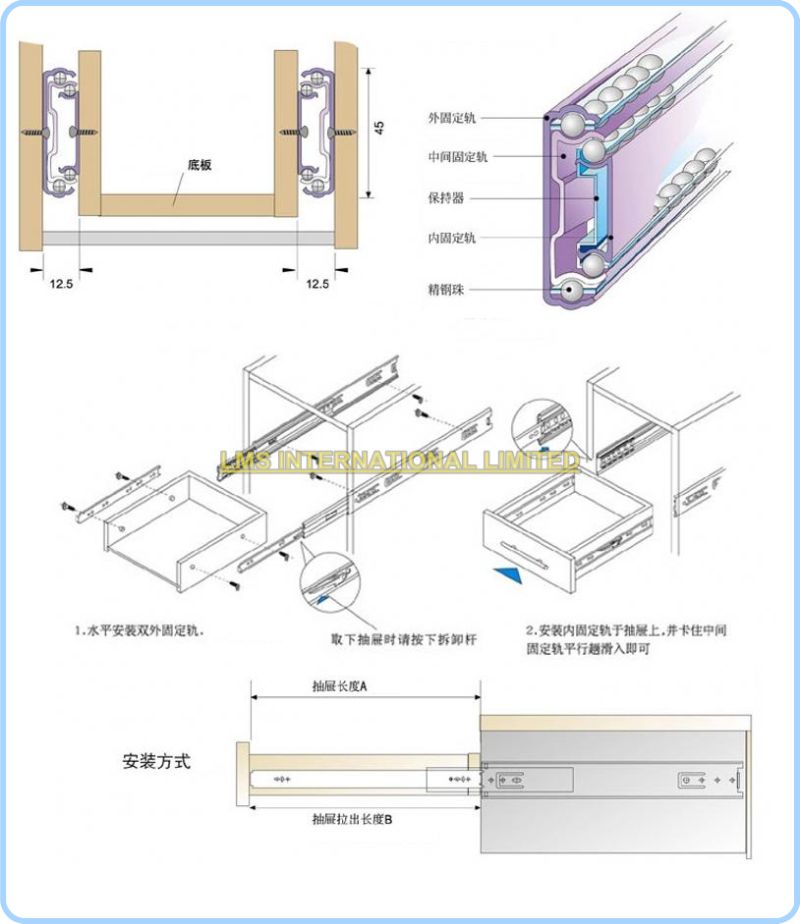

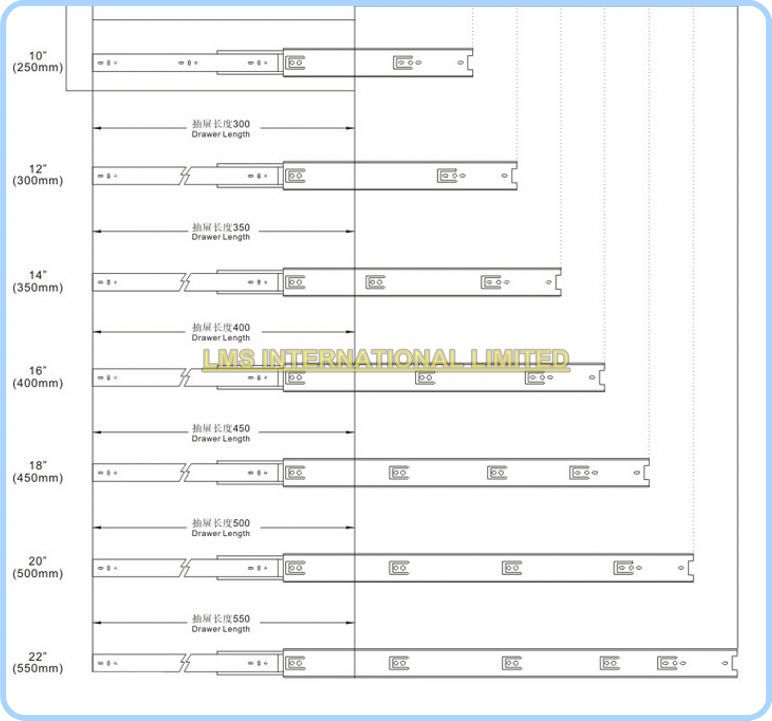

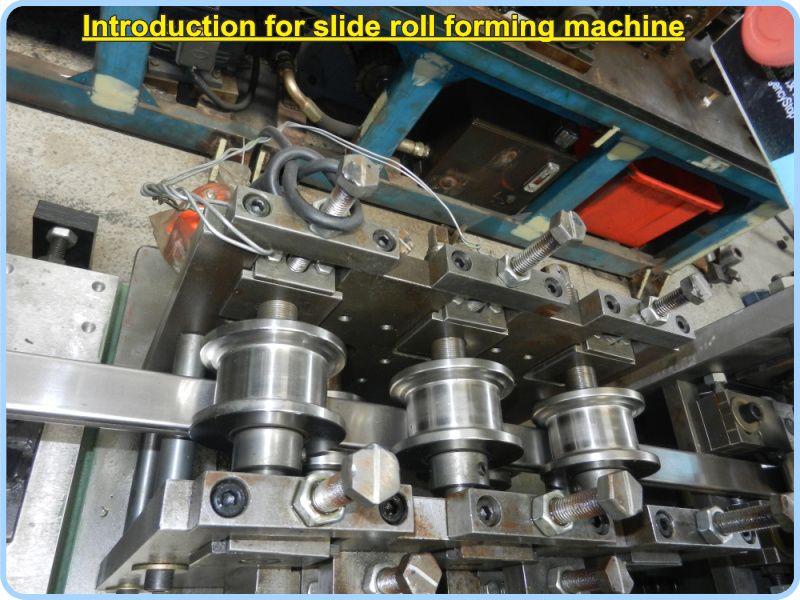

Three-section drawer slide telescopic channel drawer slide production line rolling forming machine complete line

Detail drawing of finished product line of three-section drawer slide rail

Machine slide

| thing | describe | quantity | Function | capacity | work process | strength | Weight(KG) | Size(MM) |

| 1 | Roll Forming Machine (12 Steps) | 2 sets | One set is for the inner rail and the other is for the outer rail. | 6 m/min | Uncoiler-forming-punching hole-discharging table | 380V, 3phs, 50hz | 4000 | 5400*820*950mm |

| 2 | Roll Forming Machine (16 Steps) | 1 set | Used to make the middle rail. | 6 m/min | Uncoiler-forming-punching hole-discharging table | 380V, 3phs, 50hz | 4000 | 6200*820*950mm |

| punching die | 3 sets | Installed on these three roll forming machines | Punching and cutting guides for roll forming machines | |||||

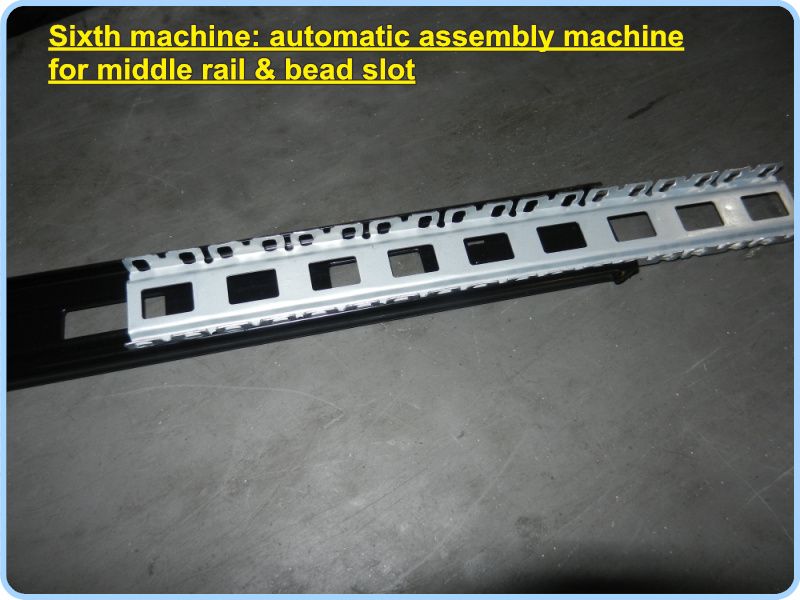

| 3 | Automatic assembly machine | 1 set | Used to assemble the beads onto the sockets and then mount the sockets to the middle rail | 20 pieces/min | 220V, 1phs, 50Hz | 600 | 2100*1100*1500 | |

| 4 | 40T Power Press machine for making Bead slots (including mold) | 1 | To make the bead groove, punch out the bead groove with a mold | Loading machine - punching (mold) - control box |

Machine slide

+

| thing | describe | quantity | Function | capacity | work process | strength | Weight(KG) | Size(MM) |

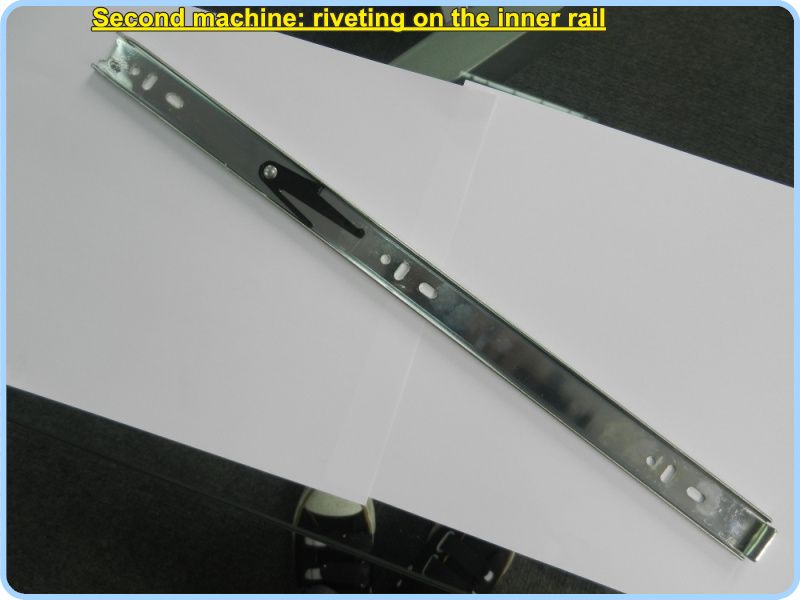

| 5 | Riveting machine | 1 set | Riveted inner rail | 60 pieces/min | 220V, 1phs, 50Hz | 160 | 950*600*1600 | |

| 6 | 16T inner rail punch (lock die) | 1 set | Press into one end of the inner rail to lock the function | |||||

| 7 | High-precision outer rail tail block punching machine | 1 set | Press the outer rail end stop | 20 pieces/min | Including punching machine and mold and control box for punching plugs and inputting rubber | 380V | 1000 | 1580*900*1880 |

Machine slide

+

| main introduction | ||||||||

| 1, | Function: | The whole production line of three-stage drawer slides (length adjustable) | ||||||

| 2, | Material: | Cold rolled or galvanized steel; HRB60+/-5 | ||||||

| 3. | Slide width: | 45mm (the price is the same for width 27mm and 35mm, but one width and one whole line, not all widths one line) | ||||||

| 4. | Material thickness: 1.2mm (not exceeding 1.5mm) | |||||||

| 5. | There are 9 machines in total, and it takes 11 steps to make a slideshow. | |||||||

Machine slide

Machine slide

LMS kitchen cabinet drawer slide roll forming machine

VIEW MORE

YOU MAY LIKE