Machinery Manufacturing CE Plate Heat Exchanger Penukar Haba Plat

- $500.00 / 1 - 4 sets

$450.00 / >=5 sets - 1 set

- Gansu Nuochen Petrochemical Complete Equipment Co., Ltd.

- Gansu, China

- Mr chen

PRODUCT DETAIL

| brand: | Nuochen | Package: | wooden box |

| Maximum flow: | 7-450 cubic meters / hour | Packaging Details: | Plywood Case/Custom Packaging |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,Alibaba Trade Assurance service | Plate material: | SS304/SS316/SS316L/Titanium/Alloy C276 |

| port: | Tianjin harbor | Mechanical test report: | if |

| Plate hole: | 0 hole, 1 hole, 2 hole, 3 hole, 4 hole | Core components: | Plates and Spacers |

| Voltage: | custom made | Core Components Warranty: | 1 year |

| After-sales service provided: | Online support | Features: | Energy saving and long service life |

| Warranty: | 1 year | Supply capacity: | 500 sets per month |

| Packaging Preview: | Marketing Type: | New Products 2022 | |

| Maximum diameter: | 25-450mm | Liquid flow rate: | custom made |

| Applicable industries: | Hotels, food and beverage factories, restaurants, food stores, construction projects, food and beverage stores, others, suitable for mining, metallurgy, petroleum, chemical, machinery, textile, paper, shipbuilding, marine development and other industrial fields | weight: | 40kg |

| Plate thickness: | 0.5mm,0.6mm,0.7mm,0.8mm,1mm | Certification: | ISO9001:2015 |

| Video external inspection: | if | structure: | Plate Heat Exchanger |

| Main selling point: | energy saving | place of origin; place of origin: | Gansu, China |

| Showroom location: | not any | Gasket Material: | NBR HNBR EPDM H-EPDM S-EPDM VITOM |

| Health status: | new | Dimensions (L*W*H): | Depends on specific model |

| Maximum working pressure: | custom made | range of working temperature: | custom made |

product description

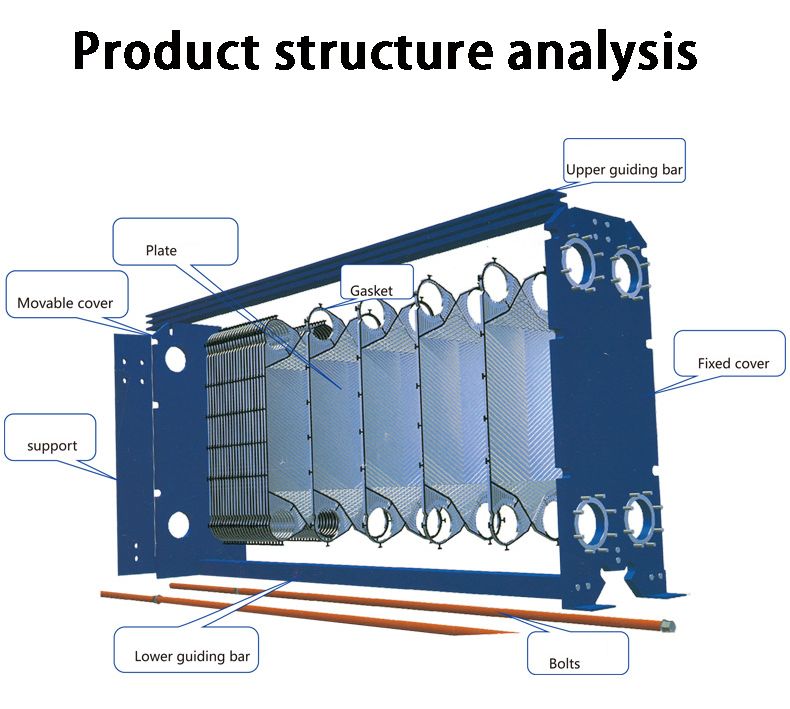

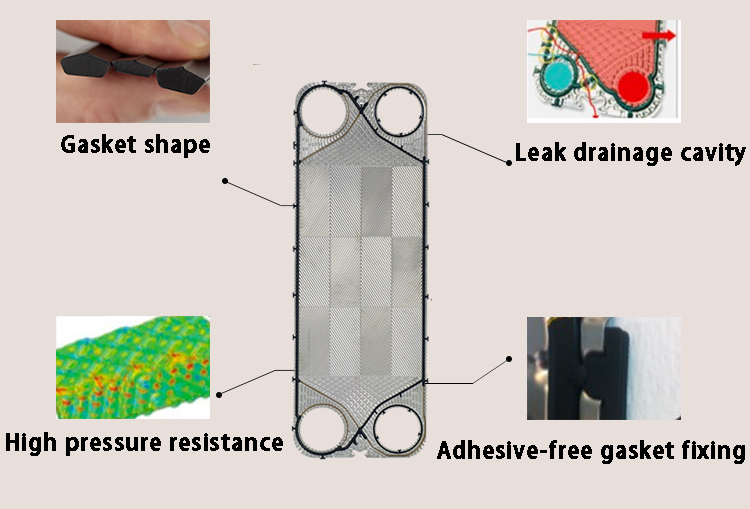

Detachable Plate Heat ExchangerIt is made of several heat exchange plates (corrugated metal plates) sealed with gaskets at a certain distance, heat exchange through the plates, and pressed with clamping studs. Plate heat exchangers are ideal equipment for liquid-liquid and liquid-vapor heat exchange.

Product features: high efficiency and energy saving, heat transfer coefficient between 3000 ~ 4500kcal/m2 °C h; the plates are closely arranged and the structure is compact; the splint is clamped by clamping bolts, which is easy to disassemble and clean; the sealing groove is provided with a drainage channel, Various media will not collude.

design pressure | 3.0MPa |

Connection size | DN25-DN500 |

Operating temperature | -40℃-180℃ |

Model | BR series |

liquid flow rate | custom made |

Certification | CE/ISO9001:2015 |

Scope of application | Metallurgy, mining, petroleum, chemical industry, electric power, medicine, food, chemical fiber, paper, textile, ship, heating, Other departments, can be used for heating, cooling, evaporation, condensation, sterilization, waste heat recovery, etc. |

detailed picture

Click for more details

Product parameters

Plate material | for fluids |

Stainless steel (SUS304.316) | Purified water, river water, edible oil, mineral oil |

TI, T-palladium | Seawater, brine and salt chemicals |

20Cr, 18Ni6Mo(254SMO) | Dilute sulfuric acid, dilute brine solution, inorganic aqueous solution |

you | High temperature, high concentration caustic soda |

Hastelloy (C276, D205, B2G) | Concentrated sulfuric acid, hydrochloric acid and carbonic acid |

Gasket Material | Temperature range (℃) | Corrosion resistance |

Nitrile rubber | -20-110 | It has good corrosion resistance to chain hydrocarbons (propane, butane, etc.), mineral oils, animal and vegetable oils, aliphatic hydrocarbons, ethylene glycol, and dilute acid and alkali solutions. |

Hydrogenated nitrile rubber | -20-165 | It has good corrosion resistance to chain hydrocarbons (propane, butane, etc.), mineral oils, animal and vegetable oils, aliphatic hydrocarbons, ethylene glycol, and dilute acid and alkali solutions. |

EPDM rubber | -50~150 | Resistant to dilute acid, alkali and salt corrosion. Suitable for hot water, saturated steam, ethylene glycol, organic acids, sodium hydroxide, ethanol, hexadecane, esters, etc. |

EPDM rubber | -20~165 | Resistant to dilute acid, alkali and salt corrosion. Suitable for hot water, saturated steam, ethylene glycol, organic acids, sodium hydroxide, ethanol, hexadecane, esters, etc. |

EPDM rubber | -20~130 | Resistant to dilute acid, alkali and salt corrosion. Suitable for hot water, saturated steam, ethylene glycol, organic acids, sodium hydroxide, ethanol, hexadecane, esters, etc. |

fluororubber | -40~180 | Excellent corrosion resistance. Suitable for high concentrations of inorganic acids and bases and polar chemical media, mineral oils, silicone oils and silicone resins, animal and vegetable oils, chain hydrocarbons (propane, butane, mineral oils, etc.), chlorinated hydrocarbons, fuels, non-gas resistant substances, etc. |

Neoprene (CR) | -50~100 | It is resistant to dilute non-oxidizing acids and bases. |

silicon | -65~230 | Resistant to dilute acid, alkali and salt water corrosion. |

Compressed Fiber (AFM34 SIL-4400) | 260 | Oil, water and steam (up to 160 °C), gases, salt solutions, fuels, ethanol, organic/inorganic acids, refrigerants, hydrocarbons. |

Teflon | -200~260 | It has excellent corrosion resistance. Resistant to all chemical media (including concentrated nitric acid and aqua regia) except molten metal lithium, sodium, potassium, chlorine trifluoride, high temperature oxygen trichloride and large flow of liquid fluorine. |

VIEW MORE

YOU MAY LIKE