New design solid bamboo wallboard solid strand woven wall panel bamboo ceiling for indoor and outdoor

- $38.80 / 300 - 799 square meters

$37.80 / 800 - 1499 square meters

$36.80 / 1500 - 1999 square meters

$35.80 / >=2000 square meters - 300 square meters

- Guangzhou Qichuan Wooden Products Co., Ltd.

- Guangdong, China

- Mr Qingshan Zhu

| Payment Terms: | L/C,Western Union,T/T; | Colour: | Natural; |

| Wood species: | Strand woven; | Surface Treatment: | Pre-Finished; |

| Project Solution Capability: | Others; | Brand Name: | Greenvills; |

| Place of Origin: | Anhui, China; | After-sale Service: | Online technical support; |

| Type: | Solid strand woven bamboo wallboard; | Usage: | Indoor and Outdoor; |

| Surface treatment: | Carbonized Natural oil; | Product Type: | Solid Stranded Bamboo; |

| Application: | Apartment; | Port: | Shanghai; |

| Thickness: | 18mm; | Technic: | Cold press and hot press; |

| Installation Type: | Glue/Nail/Staple; | Package Preview: | ; |

| Joints: | T&G; | Packaging Detail: | Cartons and pallets; |

| Grade: | Select grade; | Design Style: | Modern; |

| Supply Ability: | 20000 Square Meters per Month; | Warranty: | At least 20 years,More than 5 years; |

| Model Number: | BM-Wall panel; | Bevel: | Micro-bevel; |

| Installation Location: | Above Grade/Wood Subfloor; |

New design solid bamboo wallboard solid strand woven wall panel bamboo ceiling for indoor and outdoor:

|

Size: |

2500x140x18mm |

|

Specifications: |

Color: Natural Joint: Tongue&Groove(we also have clicks) Grade: Select grade(The grade can be changed by customer's requirements) (We can manufacture many other surfaces like distressed andhandscraped...) Formaldehyde emission: CARB standard; Certificates: ISO9001, CARB, FSC; |

Product Display:

Product Display:

1.Fast response

2.Free samples by DHL/UPS/TNT after confirmation.

3.Lead-time:For Bamboo flooring: 15 working days after receiving deposit

For Solid wood flooring: 25 working days after receiving deposit

For Engineered flooring: 35 working days after receiving deposit

4.Documents:Certificate of origin (CO),Fumigation Certificate, B/L,Phytosanitary Certificate(PC),Packing list,Commercial Invoice if needed.

5.Inspection:We will provide you photos on random boxes checking i.e: Mositure content,gloss,joints,colour,warping degree,size,the integrity of boxes and pallets, loading process

|

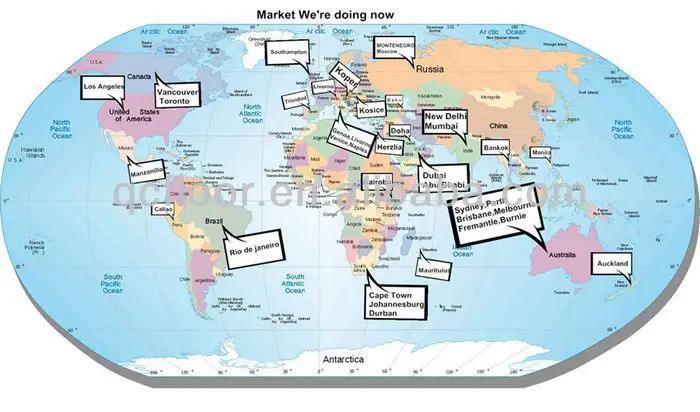

Qichuang Wooden Products Co., Limited, with manufacturing base at Zhejiang and Panyu, is a growing manufacturer of engineered wood flooring structured multi-ply,3-ply,2-ply and relevant accessories like mouldings,underlays,etc. At the present, 80% of our products are successfully marketed in Europe, North America and East Asia,among them some are custom-labelled. We live by our alway-held principle: Listen to customers’ needs; innovate to provide a solution; stable quality and good price. We are looking for flooring wholesalers, traders,building marts and project contractors from around the globe to create mutually beneficial cooperation. |

Factory&showroom display:

Our customers:

Q. What's the structure of engineered wood flooring?

A. Engineered wood flooring generally means multi-ply, 3-ply and 2-ply structured flooring.

They are criss-crossed to achieve structure stability and endurance.

You can find structure graph in PRODUCT page.

Q. What's "square edge", and "bevel edge"?

A. It means the shape of board edge, it's vividly displayed when two boards are jointed together.

Please find the below two graphes and you will have a hands-on comprehension.

Q.Is engineered wood flooring a good, environmentally friendly product to use?

A. Engineered wood flooring in your home is recyclable, natural, biodegradable and durable. It is a statement of value and beauty that is also a functional asset which is easy to maintain.

It's made of wood. Trees are renewable natural sources, they regenerate naturally and are replanted. Although wood products make up 47% of all industrial raw materials manufactured, they only use 4% of energy needed to produce these materials.

Q. What's the advantage of engineered wood flooring in comparison with solid wood flooring?

A. Engineered wood flooring has many advantages, see below:

a) Easy and fast to install, installation cost is low;

b) More stable with layered structure;

c) Cheaper than solid wood flooring but could increase same value and taste for your home;

d) Better suited for humid regions;

e) have a Lifespan anywhere from 25 - 100 years with good care;

f) more choices for sizes and thicknesses of top wear layer.

Q. What's the installation advantage?

A. Most engineered wood floors are recommended to be glued down or be floated.

Glued down: it's installed on underlayment materials like cork,EPE foam,etc. They can also be installed over most flat concrete slabs, ceramic tile, vinyl flooring, providing these floorings are secured well to the underfloor and that any surface wax,dust,or glaze is completely cleansed and the surface is roughened up so as to keep enough adhesion for the glue.

Floated: This is a very fast, easy and clean installation method. Floating floors are not mechanically fastened to the subfloor: instead, each plank is glued together with wood glue applied in the tongue and groove. A foam-pad(3mm-10mm) is placed between the wood flooring and the subfloor to protect against moisture, reduce noise transmission, and "soften" the floor. This is the easiest and most versatile installation method.

Q. Does it matter what width or color to use? Is one width better than another?

A. No. I would suggest using whatever width planks you prefer aesthetically. Actually a narrower plank will give you a more formal look and sense to your home. A wider plank (over 5 inches wide), will give you a more Country look and feel.

Floor Color is a personal choice that would have more to do with your personal tastes and decor. A natural light colored wood floor will go with any décor and will lighten up any room, but not use natural dark colored flooring if your room decor is very dark.

Q. Can you stain color on your engineered wood flooring?

A. Yes we can. Please offer us a color specimen, then, our painting technicians will stain the same or similar chromaticity on engineered wood flooring for you.

Generally speaking, light wood species like maple, oak, elm, birch,etc can eaily stain into darker color. But dark wood species like black walnut, ipe, sepele, teak,etc could not easily stain into any different colors.

Q. Are there different grades of engineered wood flooring?

A. Yes, natural timbers have natural characters like knots,sapwoods,wormholes,etc. So we select wood veneers and make three grades.

Wider planks like 189mm(7 inches) would inevitably have C grade mixed. Narrower planks like 90mm(3 1/2inches) would be easy for full AB grade packed. The C grade would show more light and dark boards along with more pronounced character -- with the possibility of small wormholes and knots.

For more related questions, especially the latest and best price, please feel free to contact me!

Best wishes!