PLC computer control supported 4 axis cnc controller okuma NEWKer CNC milling control system for PLC+ATC milling machine

- $480.00 / 1 - 49 pieces

$430.00 / 50 - 99 pieces

$400.00 / >=100 pieces - 1 piece

- Chengdu Newker CNC-Technology Co., Ltd.

- Sichuan, China

- Mr Nandy Lee

PRODUCT DETAIL

| Program: | User Macro Program; | Machinery Test Report: | Provided; |

| Port: | Any ports of China; | Showroom Location: | Turkey,Viet Nam,Indonesia,Pakistan,India,Russia,Thailand; |

| Weight: | 10KG; | Dimension(L*W*H): | 400*245*125; |

| Applicable Industries: | Machinery Repair Shops,Manufacturing Plant,Farms,Construction works ,Energy & Mining,Advertising Company,Macro,milling machine,machining center; | User Store Room: | 128Mb; |

| Dimension for hole: | 380*226; | After-sales Service Provided: | Video technical support,Field installation, commissioning and training,Field maintenance and repair service,Online support; |

| Function: | PLC+ATC; | Speed: | 30m/min; |

| Port: | 24input 24output; | Marketing Type: | New Product 2020; |

| Interface: | USB+RS232 Communction Port; | Place of Origin: | Sichuan, China; |

| Package Preview: | ; | Local Service Location: | Turkey,Viet Nam,Indonesia,Pakistan,India,Russia,Thailand; |

| CPU: | ARM(32bits)+DSP+FPGA; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Supply Ability: | 10000 Sets per Month 4 axis cnc control system function Router System; | Application: | MILLING MACHINE; |

| Certification: | CE; | Brand Name: | NEWKer-CNC; |

| Video outgoing-inspection: | Provided; | Core Components: | PLC,CNC,Macro,MIC,ATC,DSP; |

| Payment Terms: | L/C,T/T,Western Union; | Display: | 8 Inch Real Color LCD; |

| Packaging Detail: | 1.Industrial packing(Support plc and High-tech 4 axis cnc control system function Router System with PLC+ATC): plastic bag +styrofoam+ carton +wooden pallets 2.Commercial packing: plastic bag+styrofoam+ carton 3.As the clients' requirement; | Warranty: | 2 years; |

| Condition: | New; |

Poster

Product

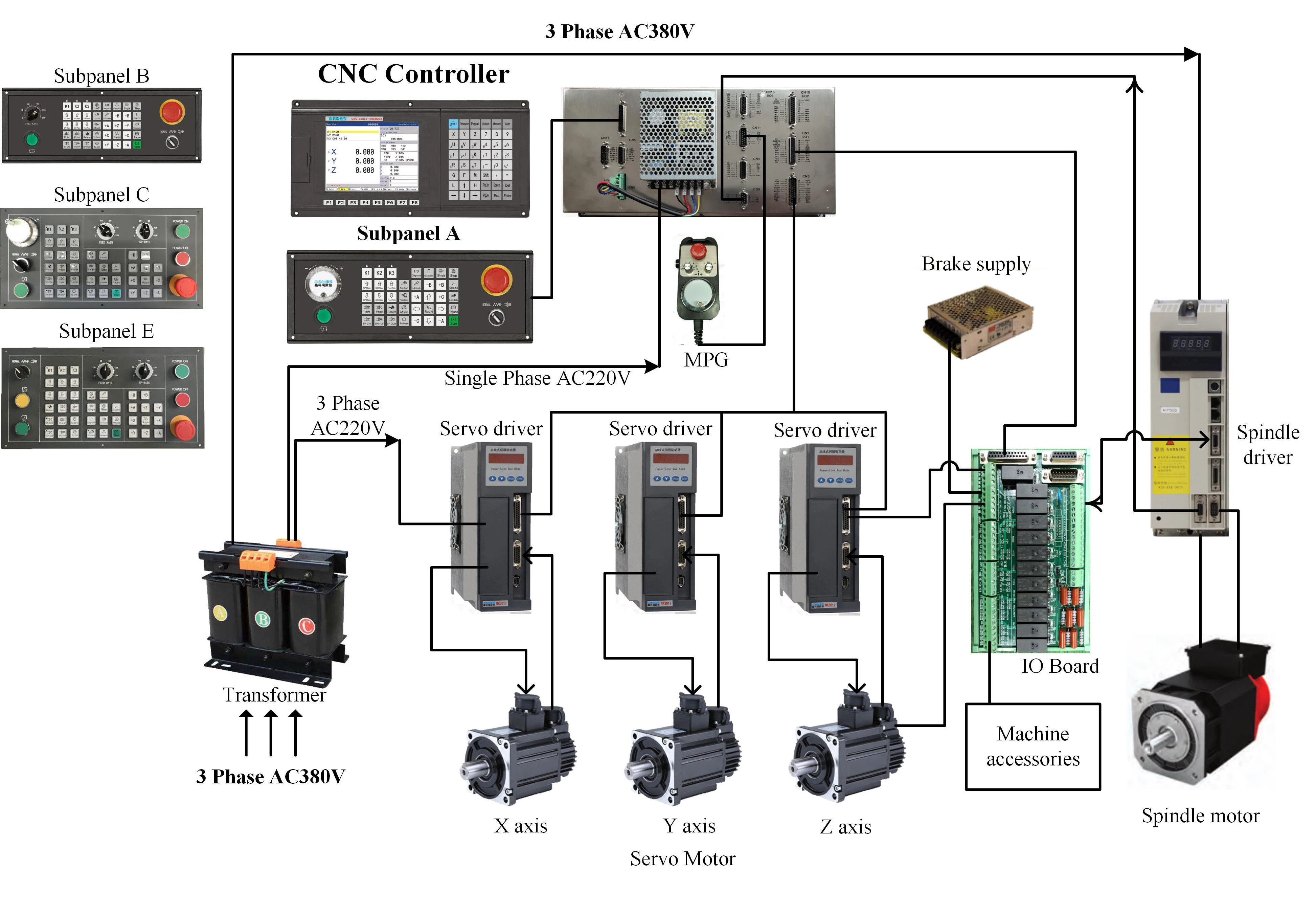

Product detail: PLC computer control supported 4 axis NEWKer CNC milling control system for PLC+ATC milling machine

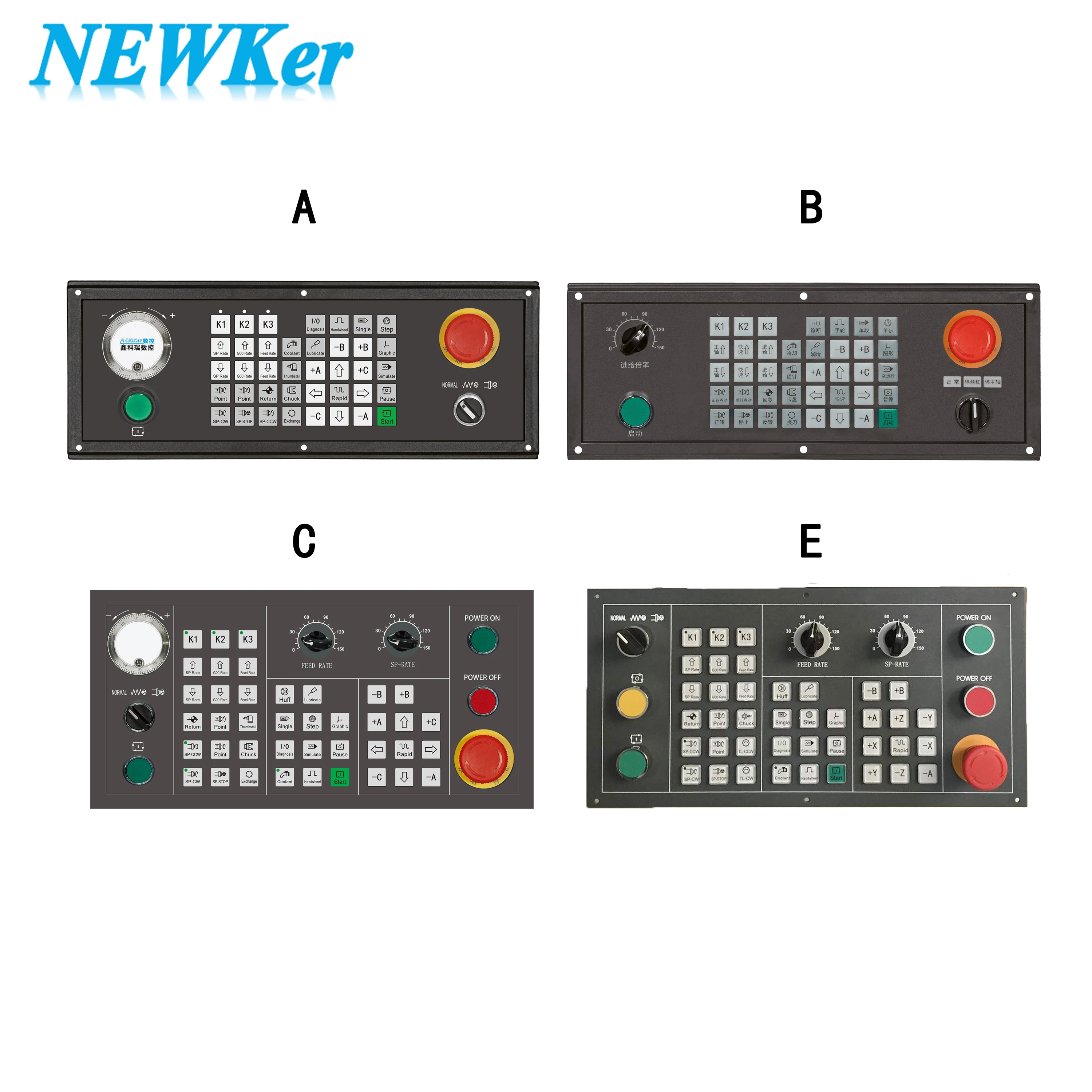

Subpanel

Parameter details | ||||||

System Function | G code shows | |||||

Number of control axis | 3~8(X,Y,Z,A,B,C,Xs,Ys) | Locate rapidly: | G00 | |||

The smallest programming: | 0.001mm | Straight line interpolation | G01 | |||

The most programming: | ±99999.999mm | Arc interpolation: | G02/03 | |||

The highest speed: | 60m/min | Thread cut: | G32 | |||

Feed speed: | 0.001~30m/min | Cycle of cutting cyliner or cone: | G90 | |||

Continuous manual: | one axis or multiple axis at the same time | Cycle of cutting end face: | G94 | |||

Line interpolation: | Straight line, arc, screw thread interpolation | cycle of cutting thread | G92 | |||

Cutter compensation: | Length of the compansation、radius nose of tool compensation | Fixed cycle of tapping | G93 | |||

Cutter compensation input: | Try to cut measuring input mode | Cycle of rough cut in excircle | G71 | |||

Spindle function: | gear、Double analog control、Rigid tapping | Cycle of rough cut at end face: | G72 | |||

Handwheel function: | panel、handheld | Cycle of closed cut | G73 | |||

handwheel processing: | The handwheel processing function | Cycle of drill deep hole at end face | G74 | |||

Screen protection: | The screen protection function | Cycle of cutting groove with external diameter | G75 | |||

Tool rest function: | Row tool rest、Electric too post 99 knife | Cycle of cutting compound thread | G76 | |||

Communication function: | RS232、USB interface | Cycle of program | G22,G800 | |||

Compensation function: | Tool compansation、Space compensation、Screw pitch compensation、Radius compensation | Local coordinate system: | G52 | |||

Edit program: | Metric/Imperial、Straight thread、taper thread and so on | Detect the instruction of skip | G31,G311 | |||

Limit position function | soft limit, hard limit | Pole coordinate | G15,G16 | |||

thread function | metric and inch format, straight thread, taper thread and so on | Metrical/Imperial programme: | G20,G21 | |||

Preread function: | Preread 10,000 short straight lines | Set coordinate, offset | G184,G185 | |||

Password protection: | Multilevel password protection | Workpiece coordinate system: | G54~G59 | |||

Input/output: | I/O 56*24 | Tool radius C | G40,G41,G42 | |||

PLC programme: | All open PLC design | Accurate locating/continuous path process: | G60/G64 | |||

Acceleration and deceleration control: | Straight line、Index | Constant linear cutting: | G96/G97 | |||

Number of encoder: | any setting | Feeding mode: | G98,G99 | |||

User macro program: | Have | Backing to start point of program: | G26 | |||

Electrical gear function: | Have | Backing to the fixed point: | G25,G61,G60 | |||

Subpanel | A type with handwheel; B type with band switch; C type with both A and B, E type | Backing to the datum point: | G28 | |||

Application: | VMC, grinding, special machine | Suspend: | G04 | |||

Macro Program: | G65,G66,G67 | |||||

Auxiliary function: | S、M、T | |||||

Function advantages

Product features

Never Crush the machine, the system with memorial function (Abosolute feature)

Needn't install hard limit with this 3 axis control wood drilling and milling machine and back to the zero point (Abosolute

feature)

Adapt bus modbus technology, ARM + DSP + FPGA technology

USB and RS232 port, DNC function of USB (NEW)

Network remote technology and could diagnose the system online (NEW)

User's storage is 128M and could be infinite number of program (NEW)

Abosolute type of motor (17bits multi circle) controlling technology (NEW)

The most moving rapid speed is 300m/min, processing speed reaches 0.01 ~ 30m/min (NEW)

The cycle of interpolation is 2ms, controlling accuracy is 0.1um (NEW)

All closed-loop with grating ruler control and the accuracy is <2um (NEW)

Preread the short line program to satisfy with high speed engraving and cutting (NEW)

Intelligent Man-Machine dialog interface (NEW)

Needn't install hard limit with this 3 axis control wood drilling and milling machine and back to the zero point (Abosolute

feature)

Adapt bus modbus technology, ARM + DSP + FPGA technology

USB and RS232 port, DNC function of USB (NEW)

Network remote technology and could diagnose the system online (NEW)

User's storage is 128M and could be infinite number of program (NEW)

Abosolute type of motor (17bits multi circle) controlling technology (NEW)

The most moving rapid speed is 300m/min, processing speed reaches 0.01 ~ 30m/min (NEW)

The cycle of interpolation is 2ms, controlling accuracy is 0.1um (NEW)

All closed-loop with grating ruler control and the accuracy is <2um (NEW)

Preread the short line program to satisfy with high speed engraving and cutting (NEW)

Intelligent Man-Machine dialog interface (NEW)

Product applications

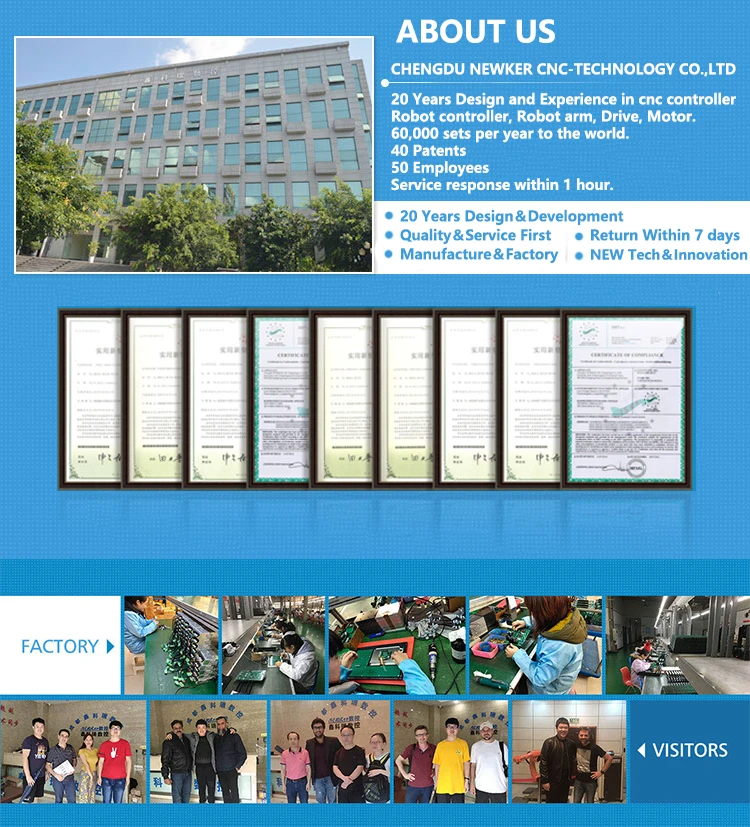

About us

Delivery procedures

FAQ

contact us

VIEW MORE

YOU MAY LIKE