PP Flat Yarn Extruder Twisting Waste Plastic Rope Making Machine

- $1000.00 /set

- 1 set

- Wenzhou Ebey Machine Manufacture Co., Ltd.

- Zhejiang, China

- Ms Cindy Mao

| Health status: | new | Main selling point: | easy to operate |

| Warranty: | 1 year | place of origin; place of origin: | Zhejiang, China |

| Function: | Simultaneous twisting and rope making on one machine | Dimensions (L*W*H): | 1750X5240X2000mm |

| port: | Ningbo Port | Marketing Type: | normal product |

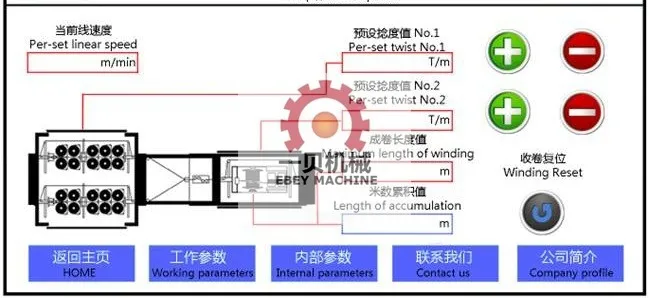

| Core components: | PLC, motor | system: | PLC and touch screen system control |

| Voltage: | 380V | payment terms: | L/C,T/T,Western Union |

| After Warranty Service: | Video technical support, online support | Video external inspection: | if |

| Twisting distance: | 12-66mm | Mechanical test report: | if |

| After-sales service provided: | Engineers can serve machinery overseas, video technical support, online support | brand: | EB |

| Packaging Details: | 1 set of 2017 top precision CNC automatic coconut coconut husk rope making machine, packed with stretch film or as customer's request | Plastic Processing: | plastic nylon pp |

| Product Category: | Twisted Braided Rope, Plastic Rope | Supply capacity: | 20 sets per month |

| Applicable industries: | manufacturing plant | Showroom location: | not any |

| Local service location: | not any | Processing type: | other |

| diameter: | M55 : 4-16 MM can be widened according to customer requirements | Certification: | ISO CE |

| Core Components Warranty: | 1 year |

PP Flat Yarn Extruder Twisting Waste Plastic Rope Making Machine

Performance and Features:

Your satisfaction is our huge motivation!

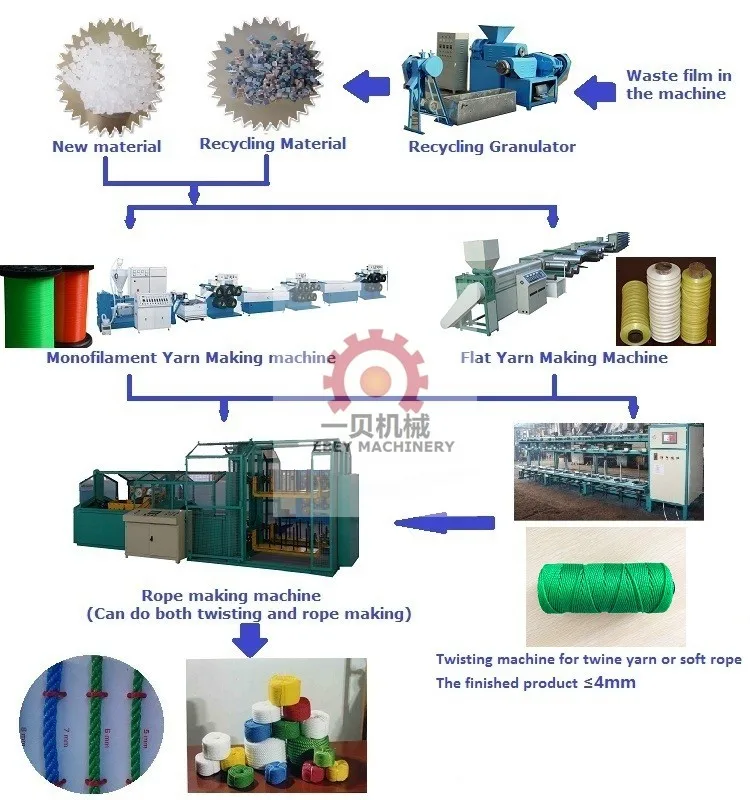

1. All of our rope making machines can use natural fibers or man-made fibers.

2. It can produce 440-4890m coil.

3. It can produce or process three-strand and four-strand ropes.

4. This machine can be twisted into multiple strands at one time to make rope.

5. The production speed is fast and the output is extremely high.

6. PLC and touch screen control

|

model |

M44 |

M55 |

M66 |

M77 |

M88 |

electromagnetic field |

|

rope range |

3-10mm |

4-16mm |

8-20mm |

10-25mm |

25-46mm |

3-10mm |

|

flyer speed |

0-max, 1200 rpm, depending on pre-torque factor |

0-max.900 rpm, depending on pre-torque factor |

0-max.450 rpm, depending on pre-torque factor |

0-max.360 rpm, depending on pre-torque factor |

0-max.300 rpm, depending on pre-torque factor |

0-max.450 rpm, depending on pre-torque factor |

|

rope laying |

S/Z |

|||||

|

one revolution per minute |

2 x rope flight speed |

|||||

|

lay length |

ANY, automatic control |

|||||

|

Pre-twist coefficient |

ANY, automatic control |

|||||

|

Take-up and take-up head |

Ø 420 mm, maximum adjustable traverse. 300 mm, barrel Ø135 mm

|

Ø 480 mm, maximum adjustable traverse. 345 mm, barrel Ø135 mm

|

Ø 670 mm, maximum adjustable stroke. 400 mm, barrel Ø210 mm |

Ø 900 mm, maximum adjustable traverse. 525mm, barrel Ø260mm

|

Ø 1000 mm x 600mm, maximum adjustable stroke 600 mm, barrel Ø260 mm

|

any |

|

Coiled, max weight |

Polypropylene 20 kg |

Polypropylene 40 kg |

Polypropylene 70 kg |

Polypropylene 170 kg |

Polypropylene 240kg, Polyester 430kg, Polypropylene 240kg, PET 430kg |

any |

Our advantage:

Fully automatic control system, PLC and touch screen control

In one continuous operation from start to finish.

Very high production speed, high output.

pp flat yarn rope making mechanism rope machine plastic processing plastic nylon pp

- No need to change gears to adjust the rope diameter.

- Twist can be fine-tuned on the touch screen, no downtime, and more, no need to replace any parts on the machine

- Even inexperienced people can learn to operate quickly and easily, 1 person can control multiple sets of ropes with different diameters.

Extruder Twisted Rope Machine Rope Machine Product Type Twisted Braided Rope

Plastic rope making machine rope machine system PLC and touch screen system control