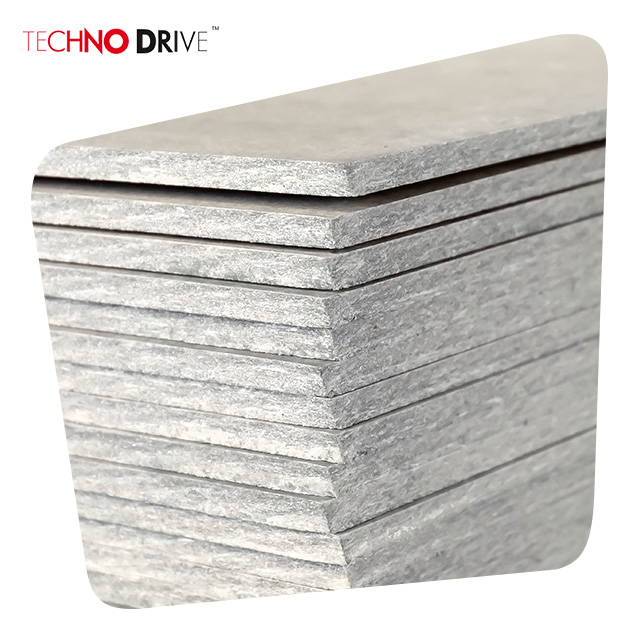

Stock of petrochemical certified gaskets available in large quantities

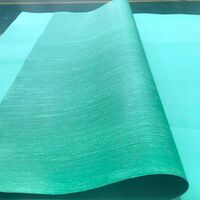

Asbestos sheets are used to cut gaskets and are designed to seal the joints of two contacting surfaces - to seal the joints between the cylinder head and the cylinder block of carburetors and diesel engines, to seal the joints of the exhaust system

| port |

|

Saint Petersburg/Vladivostok |

| processing time |

|

14 days |

| packaging details |

|

carton |

About the company

The company series produces sealing materials and their gaskets (asbestos and non-asbestos), cork and rubber corks, raw rubber of various brands, molded rubber products, gasket repair kits for cars and trucks, and special equipment series and orders.

The main consumer of the product is the businessAutomotive industry, mechanical engineering, petrochemical industry, metallurgy, construction, military-industrial complex, oil production, oilfield services and trade. Since its successful operation in 2001, the company has taken a leading position in the gasket production market, cutting about 2,000,000 pieces per month.

material production

All equipment in the material workshop was purchased in 2015. The company produces: general and special limestone (GOST 481-80), asbestos-free sealing materials and rubber compounds. The production process pays attention to the protection of the environment: in the production of paronite, a device is used to return the solvent to the production, which completely eliminates harmful emissions to the environment (photo of the machine) All materials produced comply with GOST and TU standards and are subject to internal quality control system.

Gasket cutting

Due to the large size and the special technology of cutting with the "Russian doll" method, the most effective utilization of the board can be achieved, and the effective utilization rate can reach 98%. The format of the equipment allows the production of larger area panels in 1 cycle than competitor equipment, resulting in cheaper yields per unit area. Scrap left over from the cutting process is sent to material production - this keeps them from being included in the finished product cost. As a result, finished product prices have been reduced by an order of magnitude while maintaining quality.

our staff

The production department has 250 employees. The personnel training system is set up to allow employees to adapt to work on specific equipment in a short period of time, and internal quality control standards can prevent defects and immediately recall low-quality batches. Production is 24/7 and only stops 3 days a year - from 1 to 3.

RTI production

The availability of mold making equipment and the production of rubber compounds allows us to produce not only series molded rubber products, but also non-molded products as well as custom made products.