Polyacrylonitrile Fiber Acrylic Fiber Top For Concrete Light Yellow PAN Fiber Competitive Price

- $2.39 / 1 - 99 kilograms

$2.09 / 100 - 999 kilograms

$1.99 / >=1000 kilograms - 1 kilogram

- Shandong Federal Fiber Co., Ltd.

- Shandogn, China

- Mr Peter Lee

| model: | FD9606 | Fineness: | 13 microns |

| brand: | Federal Fiber | Fiber Type: | staples |

| Supply capacity: | 1000 tons/month | place of origin; place of origin: | Shandong China |

| Packaging Details: | Inner packing 1kg Net weight PE bag Outer packing 20kgs Plastic woven bag 10000kg 20`FCL without pallet 25000kg 40`HC without pallet | port: | Qingdao, |

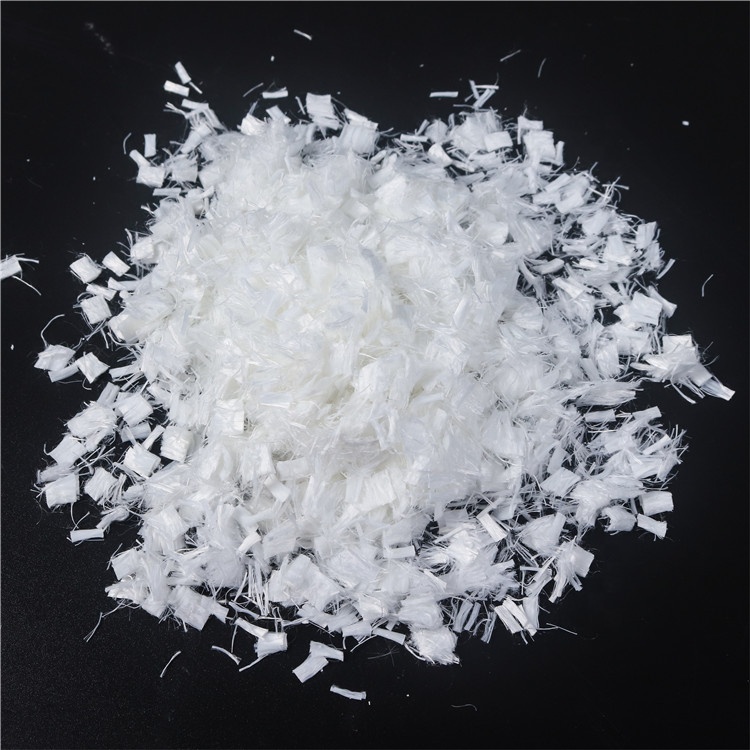

| pattern: | raw | Fiber length: | 6mm |

| payment terms: | L/C,Western Union,T/T | Material: | 100% Acrylic |

Acrylic PAN fiber has higher tensile strength, higher initial modulus and stable chemical properties than other fibers. Therefore, the fiber has acid and alkali corrosion resistance, light resistance, weather resistance, and has good dispersibility and oil absorption. In practical applications, the bonding force with the concrete matrix is strong, which improves the cohesion and fatigue resistance of the concrete, and enhances the impermeability, frost resistance and impact resistance of the concrete. Therefore, it is widely used in asphalt concrete and cement concrete engineering.

|

Wholesale engineered fibers PAN FIBER or PAN FD9606 |

|||

|

Material: |

100% Acrylic |

color: |

white |

|

unit price: |

Subject to ex-factory price or FOB Qingdao price |

Packing: |

custom packaging |

|

Minimum order quantity: |

5 tons, negotiable |

Pay: |

T/T 30% prepaid, 70% balance after getting copy of B/L |

|

Sample fee: |

free |

HS code: |

5503400000, Have import and export rights |

|

Production capacity: |

1000T/month |

delivery time: |

15 days, update order quantity (negotiable) |

|

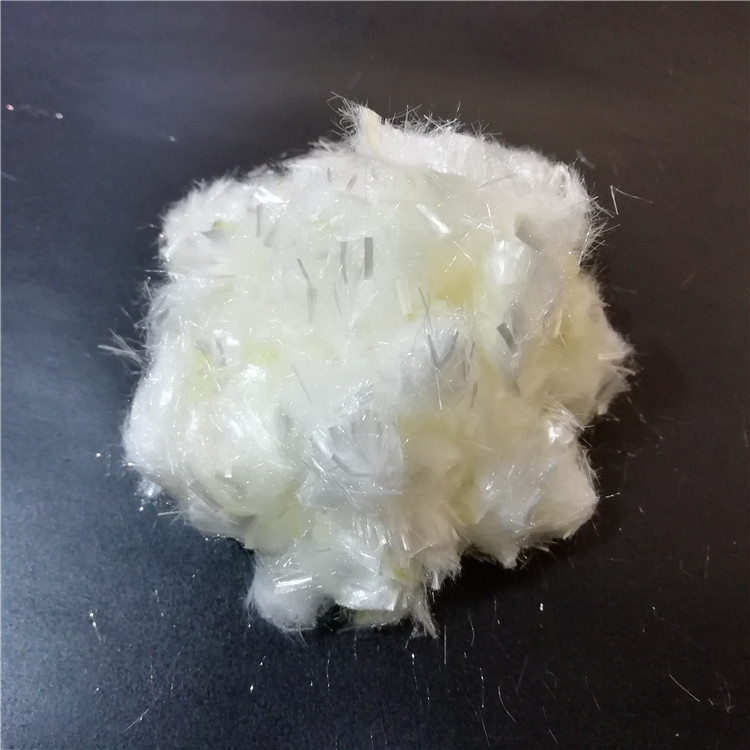

Material |

100% Acrylic |

type |

Monofilament/Multifilament |

|

diameter |

13±5μm |

density |

1.18g/cm³ |

|

melting point |

>258℃ |

burning point |

>556℃ |

|

Acid and alkali resistance |

strong |

Water absorption: |

≤2% |

|

tensile strength |

750Mpa minimum |

Elastic Modulus |

10Gpa minimum |

|

Crack Elongation: |

≥10% |

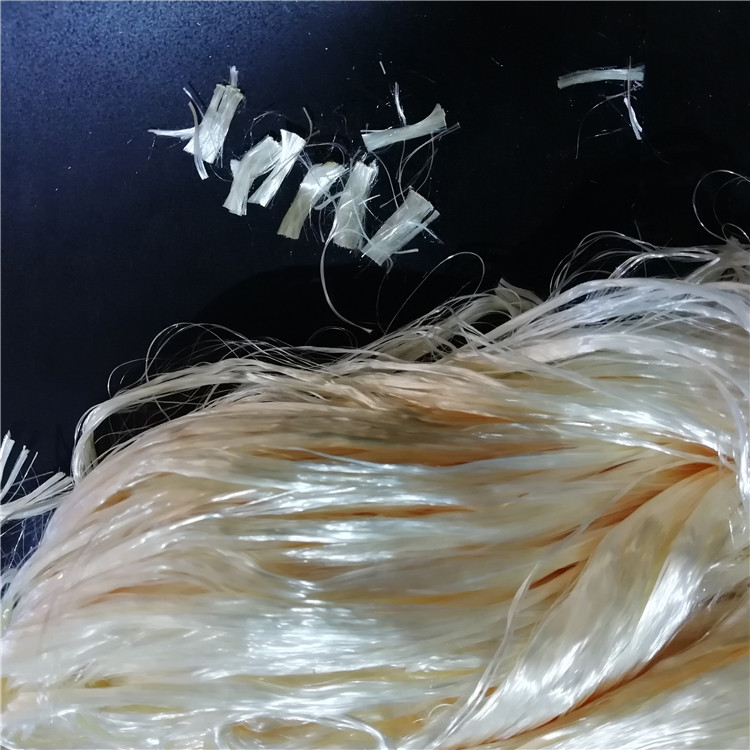

length |

6mm, 12mm, 16mm, 19mm .. .. or customized. |

|

Instructions for use |

1-4kg/Ton, the specific quantity is according to the needs of the project. |

||

1. Adsorb asphalt through viscosifying effect, and increase the asphalt content in the mixture while keeping the viscosity of asphalt mortar unchanged. The adsorption of light oil in the bitumen increases the viscosity of the remaining unadsorbed bitumen. The high temperature stability of the asphalt mixture increases with the viscosity (resistance to flow deformation) of the asphalt mineral fiber mixture.

2. Toughening enhances the bonding force between asphalt, cement binder and aggregate surface to prevent spalling and improve water erosion resistance. Improve the low temperature deformation ability and toughness of asphalt mortar and cement mortar, and reduce low temperature cracking. Fibers play an orientation role in the deformation process of asphalt mortar, which greatly improves the deformation following ability of asphalt mixture.

3. The fiber-reinforced asphalt and cement mixture has good fatigue resistance, and the fatigue life is significantly improved. Fiber-containing asphalt and cement mixtures have good impact toughness and are especially suitable for asphalt overlays on old cement concrete pavements. It improves the wear resistance of asphalt and cement mixture mixed with fiber, and can be used in special places such as anti-skid pavement and tracked vehicle pavement.

4. The volume of asphalt adsorbed by most fibers expands slightly after filling, which can effectively reduce the voids of asphalt pavement, reduce the size of voids, and improve the uniformity of void distribution. The use of water-enhancing fibers can improve the bleeding ability of asphalt mixture, shorten the residual time of water in asphalt pavement, and reduce water damage.

5. Because it has more properties than other fibers, it further improves its toughness, impact resistance and crack resistance in cement concrete and cement products.

1. New asphalt concrete pavement;

2. Old asphalt concrete pavement covering layer;

3. Repair of asphalt concrete pavement;

4. Cold patching and filling of asphalt concrete pavement;

5. Rigid bridge deck paving;

6. Cement products such as precast concrete panels;

7. Cement concrete pavement, bridge deck, aircraft, etc.

8. Ports, deep-water wharves, detours and severe cold areas;

9. Anti-collision walls and anti-shock baffles for expressways; Reservoirs, swimming pools, sewage treatment tanks; Face-plate dams for water conservancy reservoirs; Waterproofing works for basement side walls, floors, roofs and other structures.

|

inner packaging |

Outer packaging |

20` FCL without pallet |

40`HC without tray |

|

1 kg net weight per PE bag |

20kg per plastic woven bag |

10000kg |

25000kg |

|

The packaging method is different, and the loading amount is also different. |

|||

Other Products

-

Non Woven Monofilament Polypropylene Fiber, Low Price Concrete PP Fiber$1.89 - $3.20 / kilogram

Non Woven Monofilament Polypropylene Fiber, Low Price Concrete PP Fiber$1.89 - $3.20 / kilogram