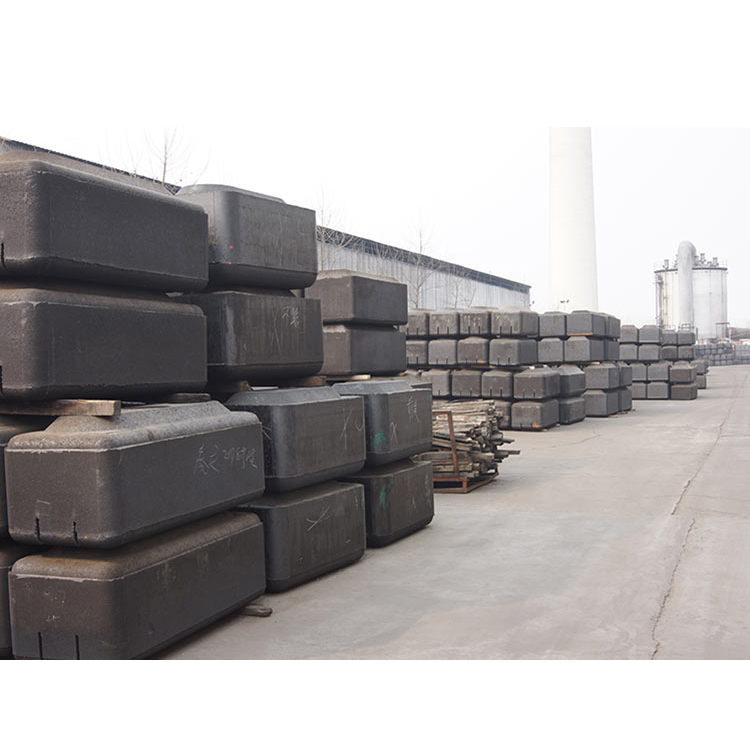

Pre-baked carbon anode, Pre-baked anode block

- $300.00 / >=10 pieces

- 10 pieces

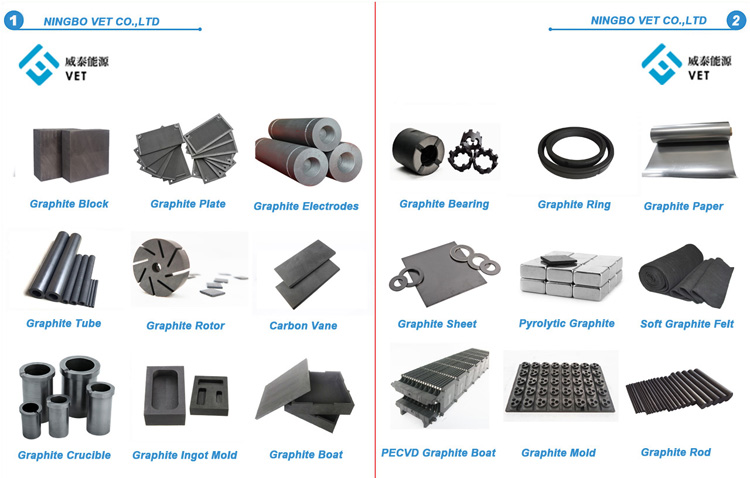

- Ningbo Miami Advanced Material Technology Co., Ltd.

- Zhejiang, China

- Ms Xianer Yeh

| Yangs module: | 4-5.5 GPA | Compressive strength: | 32 MPa |

| chemical composition: | carbon | Packaging Details: | Bulk or according to customer requirements |

| Operating temperature: | 1000~2000 | Product Category: | prebaked anode |

| Revolt: | 55-62uΩm | Actual Density: | 2 g/cm3 |

| port: | Tianjin/Shanghai/Ningbo/Shenzhen | Supply capacity: | 3000 tons per month |

| application: | Smelting/Casting/Electrode | C content (%): | 98% |

| model: | Anode 1001 | Origin: | Zhejiang, China |

| Apparent density: | 1.52-1.58 g/cm3 | payment terms: | L/C, Western Union, T/T, MoneyGram |

| brand: | veterinary | Breathability: | 0.5-1.5npm |

| Thermal Conductivity: | 3-4.5 |

Advantage:

1. The CO2 reaction residue can reach more than 91%, and the air reaction activity can reach more than 96%; the life of the aluminum electrolytic cell is 30-33 days.

2. Higher thermal shock resistance

Heat exposure: <4*10

Thermal conductivity: <3W/mkl

3. Higher current density

Current density: >0.8A/cm2

4. Reduce resistivity

Resistivity: 55-56μΩm

Anode specification

|

series

|

property |

unit |

standard method |

scope |

|

1 |

actual density |

g/cubic centimeter |

ISO 8004 |

2 minutes |

|

2 |

Apparent density |

g/cubic centimeter |

ISO 12985 |

1.52-1.58 |

|

3 |

air permeability |

new project management |

ISO 15906 |

0.5-1.5 |

|

5 |

Compressive strength |

N/mm2 |

ISO 18515 |

40-48 |

|

6 |

Youngs module |

grade point average |

ISO 12989 |

4-5.5 |

|

7 |

Bending strength |

N/mm2 |

ISO 12986 |

8 - 10 |

|

8 |

Spey. electric. resist |

micro ohms |

ISO 11713 |

55-62 |

|

9 |

Cafe. Lin. Hot |

Micron/(km) |

ISO 14420 |

3.75-4.5 |

|

10 |

Thermal Conductivity |

W/(km) |

ISO 129087 |

3-4.5 |

|

11 |

Ash |

% |

ISO 8005 |

max 0.5 |

|

12 |

air reaction residue dust lost

|

% % %

|

ISO 12989-1

|

75 – 85 4 - 8 10 - 20 times

|

|

13 |

Co2 reaction residue dust lost |

% % % |

ISO 12988-1

|

84 – 95 3 - 8 6 - 14 |

|

14 |

element S V iron f calcium aluminum you Si |

% millionth // // // // // |

ASTM D6376

|

0.5 – 2.5 30 - 320 100 – 600 150 – 600 50 – 200 150 – 600 40 – 200 50 - 300 |