Small Automatic Single Tank Industrial Carbonator Beverage Co2 Mixing Machine,Carbonated Drink Mixer

- $2800.00 / 1 - 1 sets

$2500.00 / >=2 sets - 1 set

- Zhangjiagang Drinks Packaging Technology Co., Ltd.

- Jiangsu, China

- Mr Chaman xie

| Machinery Test Report: | Provided; | Carbon dioxide content: | Freely adjustable; |

| Voltage: | 220v / 380v (Customized); | Port: | Shanghai Port; |

| Experience: | 20 Years; | Working Pressure: | 0.05-0.15Mpa; |

| Marketing Type: | New Product 2020; | Pump brand: | Nanfang; |

| Product Name: | Co2 drinks mixer; | Applicable Industries: | Food & Beverage Factory,Wine factory; |

| Supply Ability: | 2 Sets per Month; | Control system: | Buttom; |

| Weight: | 450 KG; | Application: | Carbonated Beverage / co2 Drink; |

| Condition: | New; | Video outgoing-inspection: | Provided; |

| Processing: | Mixer; | Place of Origin: | Jiangsu, China; |

| Material: | Stainless Steel SUS304; | Dimension(L*W*H): | 1600*1050*2200mm; |

| Core Components: | Pressure vessel,Pump; | Warranty of core components: | 2 years; |

| Capacity: | 1000L/H, 2000L/H, 3000L/H; | Power: | 2200; |

| Showroom Location: | Canada,United States,Mexico,South Korea; | Processing Types: | Carbonated Beverage; |

| Package Preview: | ; | Warranty: | 2 years; |

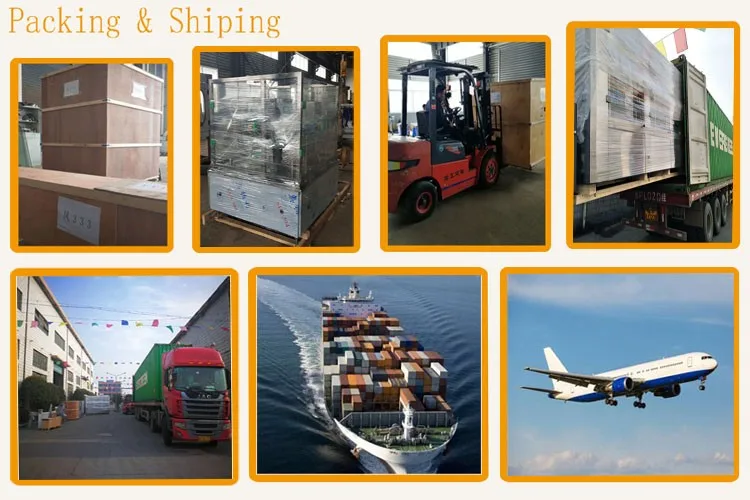

| Packaging Detail: | Standard fumigation-free export wooden box packaging.; | Payment Terms: | L/C,Western Union,T/T,MoneyGram,Cash; |

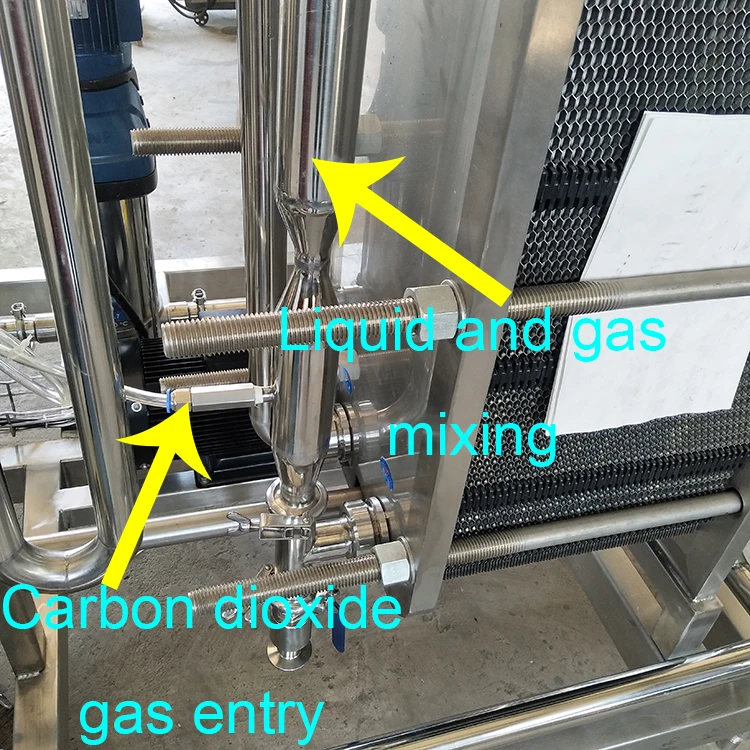

| Function: | Mixing carbon dioxide with beverage; | Brand Name: | Drinks; |

Production capacity | 1000-1500L | ||||

The range of syrup and water regulation | 1:3-1:10 | ||||

Water content | > 2.5 (co2: H2 o volume ratio) | ||||

Chilled water inlet temperature | 0-4 (℃) | ||||

Pre-carbonation tank, syrup tank working pressure | 0.05 to 0.09 (M pa) | ||||

Working pressure of storage tank | 0.2 to 0.5 (M pa) | ||||

Power (kw) | 2.2 | ||||

We use a food grade stainless steel 304 pipe to connect to the mixer and the filling machine. The mixed liquid is piped into the filling machine and the liquid into the bottle.

Q. Are you a trading company or manufacturer?

A: We are manufacturer ,we have our professional manufacturing teams and technicians.

Q: Do you have technical support?

A: Our company is responsible for installation and debugging of equipment, meanwhile, responsible for the technology and operation training for user operator.

Q: How is your delivery time?

A: Generally speaking, the sample order takes 5-7 days, and it takes 15-25 working days for the bulk order after receiving the payment. The exact delivery time depends on the project project and the number of orders.

Q: How do you make our business long-term and good relationship?

A1. We maintain good quality and competitive prices to ensure our customers benefit;

A2. We respect every customer as our friend, we sincerely do business with them and make friends with them, no matter where they come from. We are partners.

Transport Port : Shanghai Port.

Transportation: By van ,by train, by plane.

Packaging Details :Machine will be packed by PVC film+ standard wooden case or carton.

Wooden case suitable for long distance ocean shipping.