Sole injection molding grade high elastic TPE SEBS modified pellet raw material TPE SEBS pellet

- $800.00 / 1 - 9 pieces

$600.00 / 10 - 49 pieces

$400.00 / >=50 pieces - 1 piece

- Henan Hongke New Material Technology Co., Ltd.

- Henan, China

- Ms Nicole W

PRODUCT DETAIL

| Supply capacity: | 300 metric tons per month | sample: | freely |

| Package: | 25kg/bag | model: | KY-L0244A |

| port: | Tianjin Port, Qingdao Port, Shanghai Port, Ningbo Port | hardness: | 0A-100A |

| Packaging Details: | 1.25kg per package, paper plastic bag 2. All packages can be customized. 3. Inner packing plastic bag, good quality | MOQ: | 2 tons |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Package preview: | |

| Origin: | Henan, China | density: | custom made |

| delivery time: | 7-15 days | brand: | Hongke |

| grade: | injection molding | application: | Yoga mats, car mats, dolls, wires and cables |

| color: | custom color | product name: | Thermoplastic Elastomer Granules |

Product Description

scope of application

application:

Sports shoes, travel shoes, ski boots, hiking boots and other sporting goods steel wire ropes and golf leather hoses, tapes, rubber sheets and other industrial rubber products. Transmission belt, conveyor belt waterproof membrane, film, raincoat. High-end, high-transparency toys, adult products, suction cup materials, sports equipment and sealing rings, etc.

Household appliance casings, handles and other stationery, toys, daily necessities, etc. Automobile bumpers, instrument panels, steering wheels, wiper strips, gears, etc.

Plastic surgery appliances, plaster substitutes

detailed drawing

thermoplastic elastomer

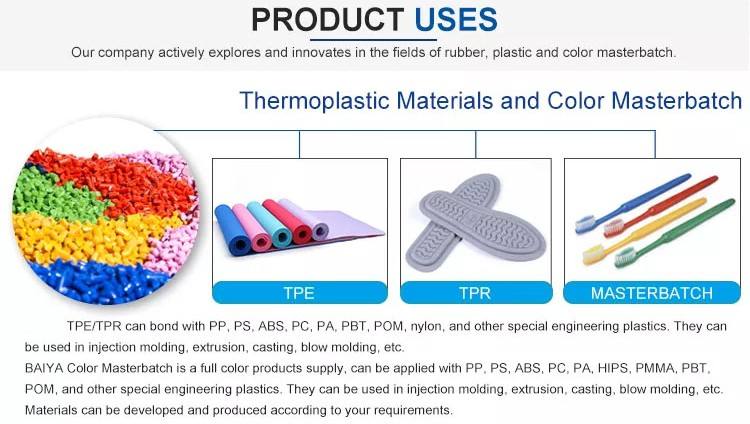

TPE (Thermoplastic Elastomer) is a thermoplastic elastomer material with high strength, high resilience, injection molding processing, wide application range, environmental protection, non-toxic safety, and excellent colorability. Thermoplastic elastomers have both the processing properties of thermoplastics and the physical properties of vulcanized rubber, which can be described as combining the advantages of plastics and rubber. Thermoplastic elastomers are replacing what was once only vulcanized rubber.

Soft, weather-resistant, fatigue-resistant, wide temperature range, excellent processing performance, no need for vulcanization, recyclable, secondary injection molding, and can be coated with PP, PE, PC, PS, ABS and other base materials. It can also be formed alone.

Soft, weather-resistant, fatigue-resistant, wide temperature range, excellent processing performance, no need for vulcanization, recyclable, secondary injection molding, and can be coated with PP, PE, PC, PS, ABS and other base materials. It can also be formed alone.

Features:

1. No special processing equipment is required, and it can be processed by general thermoplastic molding machines.2. The production efficiency is greatly improved.It can be directly injection molded with a rubber injection molding machine. Since no vulcanization is required, the molding time is very short. It can be directly produced and processed by an extruder, and the production efficiency is greatly improved.3. Easy to recycle and reduce cost.The waste generated during the production process (flying burrs, extruded waste rubber) and final waste products can be directly recycled and reused; used TPE old products can be recycled after simple regeneration, reducing environmental pollution and expanding renewable resources source.4. Energy saving. Most thermoplastic elastomers do not require curing or the curing time is very short, which can effectively save energy. Take the production energy consumption of high-pressure rubber hose as an example: rubber is 188mj/kg, TPE is 144mj/kg, which can save more than 25%.Product performance:Good transparency, good elasticity, relatively low price, large design space, wide range of hardness, from super soft to 90a. Excellent transparency, gloss and comfortable handle, widely used in adult products. It has good UV resistance, weather resistance and high temperature resistance, and can be used outdoors for a long time.

Product parameters

commodity | TPE30C | Quality inspection date | |||||

thing | unit | standard | Determine the scope | Test results | Test Methods | ||

appearance | visual test | natural color | natural color | ||||

hardness | Shore A | ASTM-D2240 | 0~100 | 30℃ | Room temperature | ||

density | SP.Gr | ASTM-792 | 1.15±0.05 | 1.2 | |||

solution flow index | g/10min | ASTM-D1238 | 5-20 | 13 | |||

tensile strength | MPa | ASTM-D412 | ≥5 | 7.8 | Room temperature 500mm/min | ||

elongation | % | ASTM-D412 | ≥500 | 550 | |||

nipple strength | kN/m | ASTM-D624 | ≥20 | twenty three | |||

manufacturing process | ||||

barrel temperature | Range ℃ | Typical value °C | ||

Front section | 150-190 | 170 | ||

middleware | 150-210 | 180 | ||

rear end | 150-210 | 180 | ||

Orifice/die | 160-200 | 180 | ||

Processing temperature upper limit ℃ | 220 | |||

drying time | Generally, drying is not required. If the storage environment is humid or the product surface requirements are high, it can be dried in a hot air oven for 2-4 hours | |||

| 1. The above data are for reference only. The above data can be adjusted according to different models, molds and product requirements. 2. Do not let the material stay in the barrel for too long, please clean the machine with PE before use stop it. | ||||

VIEW MORE