Spherical 3D printing pure titanium alloy powder TC4/Ti6Al4V titanium powder Titanium metal powder

- $1.00 / 1 - 9 pieces

$0.80 / >=10 pieces - 1 piece

- Ningbo Yichou Import And Export Co., Ltd.

- Zhejiang, China

- Mr Jack Jin

PRODUCT DETAIL

| Drawing format: | 2D/(PDF/CAD)3D(IGES/STEP) | process: | CNC machining + deburring |

| port: | Ningbo | brand: | one-up |

| Supply capacity: | 1,000,000 pieces per day | Material: | customer request |

| pack: | Carton | Surface treatment: | painting |

| OEM/Design Manufacturer: | accept | ID: | Accept custom logo |

| Key words: | CNC machining parts | technology: | 20 years experience |

| Origin: | Zhejiang, China | application: | industrial equipment |

| payment terms: | L/C, D/P, D/P, T/T | model: | titanium |

| Package preview: |

Product Description

Specification

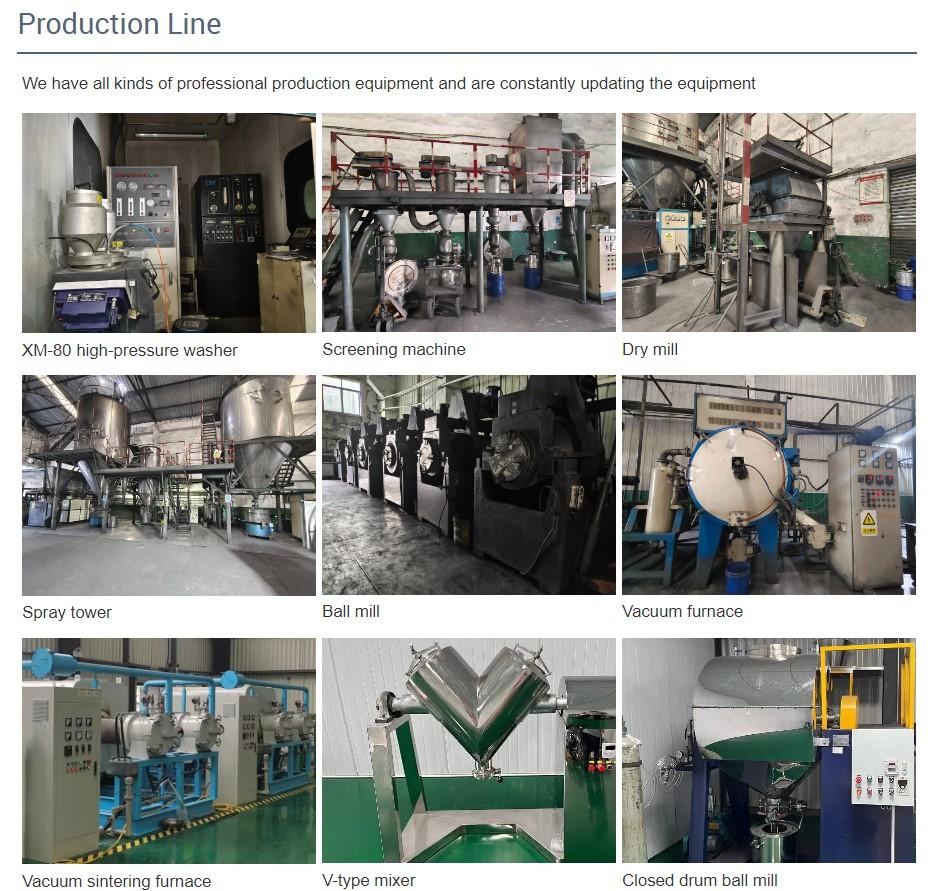

Production process of spherical titanium powder and titanium-based powder

We can form more than 20 kinds of metal and ceramic materials (such as tungsten, molybdenum, tantalum, niobium) into spherical powder

Through the self-developed induced plasma spheroidization manufacturing system. We provide high productivity,

Provide customers with fine-grained, low-cost spherical titanium powder production process.

Advantages of the induced plasma spheroidization process

The titanium powder produced by the induced plasma spheroidization production process is closer to a sphere. Obvious

The advantage of the induced plasma spheroidization production process lies in the productivity of the spherical shape and the spheroidization

The content of titanium powder is above 95%.

Characteristics of Induced Plasma Spherical Titanium Powder and Titanium-based Powder

.High mobility, no satellite balls or star clusters

.High sphericity and narrow particle size distribution

.Particle size range 0-150um

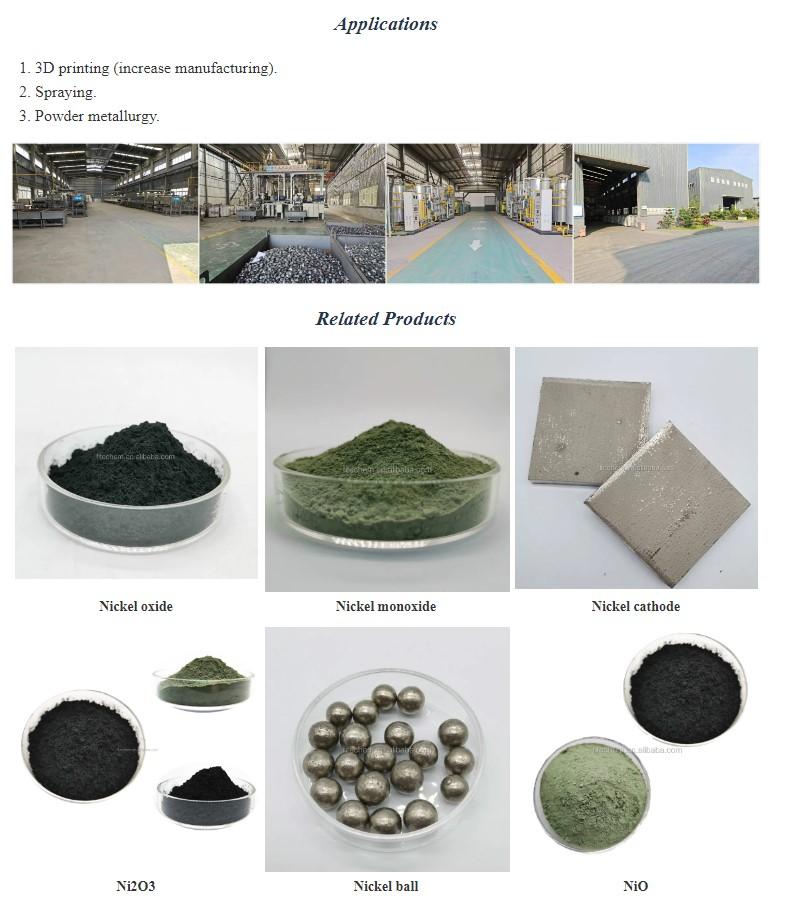

Application of Induced Plasma Spherical Titanium Powder and Titanium-Based Powder

Our spherical titanium powders are produced according to ASTM standards and are suitable for 3D printing, MIM, laser deposition, hot isostatic pressing

Pressing, surface spraying and other production processes. It is an additive for powder metallurgy and alloy materials. exist

At the same time, it is also used in cermets, surface coating agents, fireworks, aluminum alloy additives, electric

Vacuum getters, spraying and plating. Has been widely used in biomedicine, aerospace, spraying, metallurgy, fireworks, etc.

industry.

We can form more than 20 kinds of metal and ceramic materials (such as tungsten, molybdenum, tantalum, niobium) into spherical powder

Through the self-developed induced plasma spheroidization manufacturing system. We provide high productivity,

Provide customers with fine-grained, low-cost spherical titanium powder production process.

Advantages of the induced plasma spheroidization process

The titanium powder produced by the induced plasma spheroidization production process is closer to a sphere. Obvious

The advantage of the induced plasma spheroidization production process lies in the productivity of the spherical shape and the spheroidization

The content of titanium powder is above 95%.

Characteristics of Induced Plasma Spherical Titanium Powder and Titanium-based Powder

.High mobility, no satellite balls or star clusters

.High sphericity and narrow particle size distribution

.Particle size range 0-150um

Application of Induced Plasma Spherical Titanium Powder and Titanium-Based Powder

Our spherical titanium powders are produced according to ASTM standards and are suitable for 3D printing, MIM, laser deposition, hot isostatic pressing

Pressing, surface spraying and other production processes. It is an additive for powder metallurgy and alloy materials. exist

At the same time, it is also used in cermets, surface coating agents, fireworks, aluminum alloy additives, electric

Vacuum getters, spraying and plating. Has been widely used in biomedicine, aerospace, spraying, metallurgy, fireworks, etc.

industry.

VIEW MORE