The hottest Q345B steel plate H-beam building material in China

- $350.00 / >=20 pieces

- 20 pieces

- Henan Canglong Steel Structure Engineering Co., Ltd.

- Henan, China

- Ms Ada Gao

| model: | HW HM HN | Alloy or not: | is an alloy |

| Format width: | 100-900mm | Format width: | 100mm-1008mm |

| length: | 6-12 meters | standard: | British system, national standard/Japanese standard |

| Flange Thickness: | 5.5-25MMM | Supply capacity: | 5000 tons per month |

| standard: | ASTM | length: | 5.8-12 meters |

| technology: | hot rolled | Web Thickness: | 5-21mm |

| product category: | narrow flange | Packaging Details: | H beam in container or standard package |

| technology: | Hot rolled and welded | grade: | Q345B |

| port: | Qingdao/Tianjin | application: | Building Construction |

| tolerant: | ±1% | Flange Width: | 100-912mm |

| brand: | Canglong | Processing services: | Bending, welding, decoiling, punching, cutting |

| Web Thickness: | 6mm-16mm | Material: | Q235/Q235B/Q345/Q345B/SS400 |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | thickness: | 5-34mm |

| model: | I-beam | Flange Thickness: | 7-28mm |

| delivery time: | 15-21 days | application: | Large buildings, bridges, ships, hoisting |

| place of origin; place of origin: | Henan, China |

The hottest Q345B steel plate H-beam building material in China

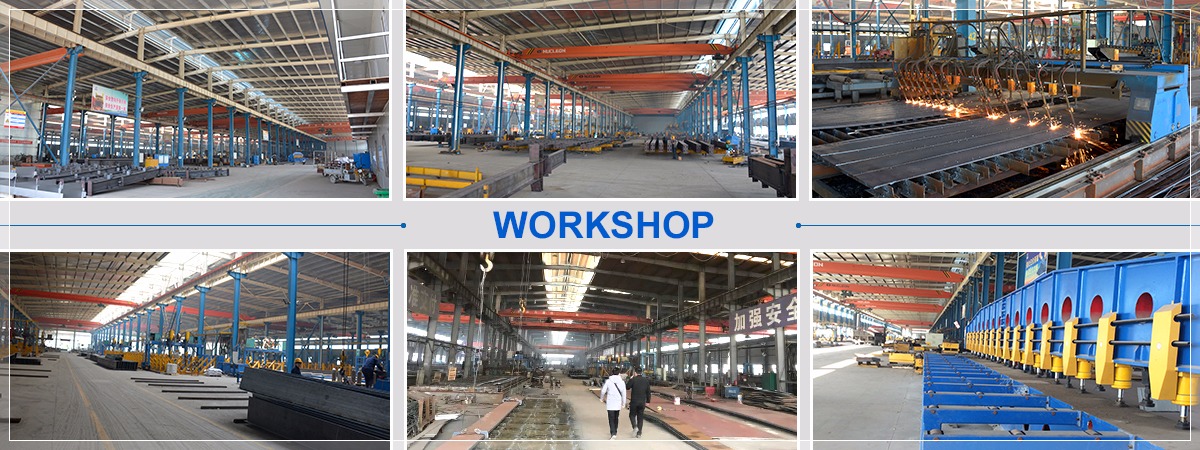

Canglong Group was established in 2003. The group consists of international marketing department, domestic marketing department, research and development department and the group's modern processing center, covering an area of 450,000 square meters and a production plant of 228,000 square meters. The products cover light steel structure, heavy steel structure, various types of color steel plates, dining tables, foam composite panels, rock wool composite panels, purification panels, C/Z steel, PU panels, purification workshops, prefabricated concrete houses, light steel villas, Green building materials such as container houses. At present, our products have been exported to more than 70 countries in the world and have been widely recognized.

Steel structure warehouse/steel structure workshop/mobile house/steel structure workshop/steel products can provide the following services:

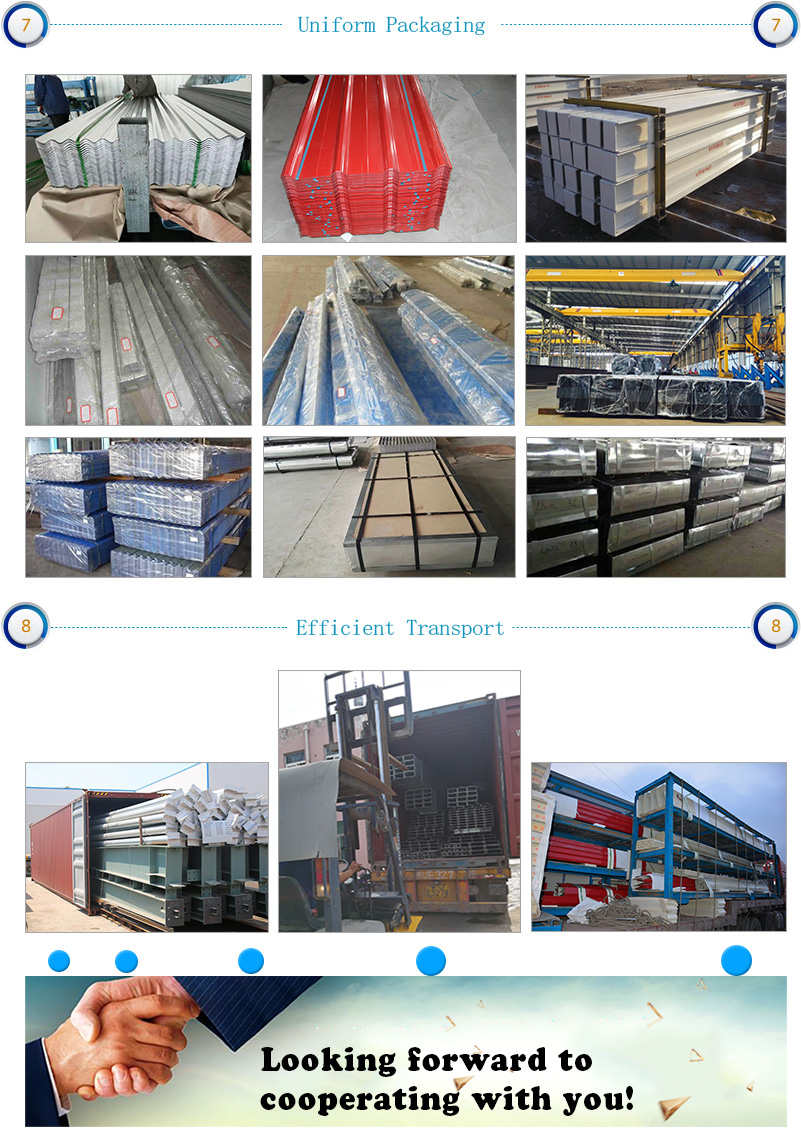

Precautions for fixed packaging, loading, transportation and unloading:

(1) There must be a special person in charge of heavy lifting, the use of fixtures must be appropriate, and strict compliance with

Hoisting rules to prevent vibration, impact, deformation or damage, and falling during the hoisting process.

(2) When loading the vehicle, there must be a special person to take care of it, check the vehicle number and packaging, and check the vehicle stack

Install it firmly, and increase the necessary binding pieces to loosen to prevent loss.

(3) Keep stable during the transportation process. When the vehicle is loaded, the long, wide and high objects must be transported by trained drivers and escorts, and signs should be set on the vehicle.

(4) Rough handling and handling by loading and unloading personnel are strictly prohibited. You should be familiar with the weight and size of the components, and check the hoisting horse and rigging to prevent accidents.

(5) Members go to the construction site and organize unloading and stacking in time.

(6) For crawler cranes carrying components, attention should be paid to the surrounding terrain and air conditions to prevent crawler cranes from overturning and component collisions.

Other Products

-

Easy Installation Best Price EPS Sandwich Panel for Roof and Wall$5.00 - $8.00 / square meter

Easy Installation Best Price EPS Sandwich Panel for Roof and Wall$5.00 - $8.00 / square meter -

ral 4013 color coated iron sheet ppgi color coated steel$2.19 / meter

ral 4013 color coated iron sheet ppgi color coated steel$2.19 / meter