Tobacco seed dyeing machine for agriculture and farm

- $37700.00 / 1 - 1 sets

$17700.00 / >=2 sets - 1 set

- Yichun Wanshen Pharmaceutical Machinery Co., Ltd.

- Jiangxi, China

- Ms Wonsen Liu

| Dimensions (L*W*H): | 1100x700x2500 | Supply capacity: | 50 agricultural and farm tobacco seed coaters per month |

| Video external inspection: | if | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| product name: | Tobacco Seed Coating Machine for Agriculture and Farm | volume: | 7L |

| Health status: | new | Showroom location: | Egypt, Germany, Indonesia, Pakistan, Russia |

| Power (kW): | 7 | port: | Shanghai/Shenzhen |

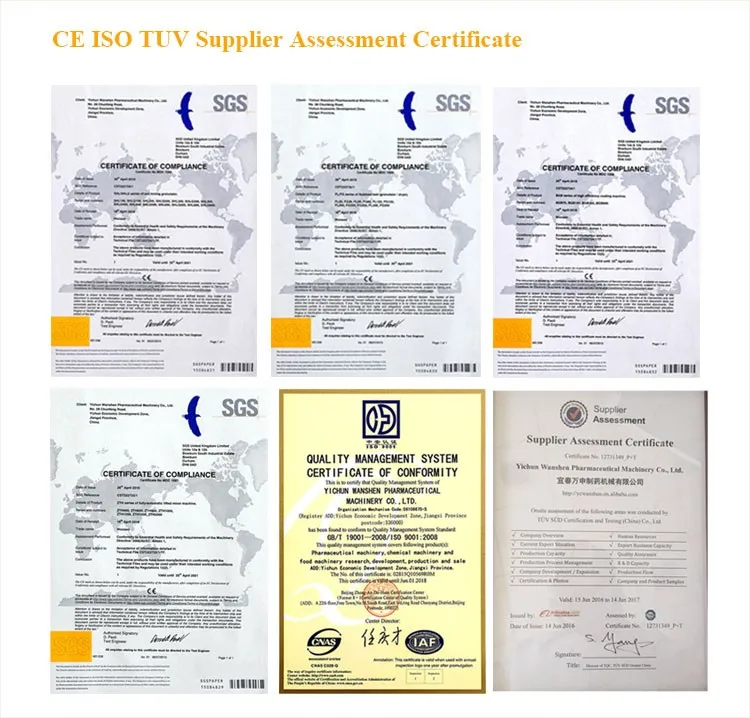

| Certification: | CE, ISO | Core Components Warranty: | 2 years |

| Core components: | PLC, bearing, motor | Packaging Details: | Agriculture and Farm Tobacco Seed Coating Machine Standard Wooden Box Packed in Film First, then Plastic Bag, Finally Wooden Box Size According to Equipment Size |

| Applicable industries: | Manufacturing plants, food and beverage plants, agriculture and pharmaceutical industries | place of origin; place of origin: | Jiangxi, China |

| Product capacity: | 1kg/batch | type: | Coater |

| Local service location: | Egypt, Italy, Germany, Indonesia, Pakistan, Thailand, Kyrgyzstan | Main selling point: | multifunctional |

| Mechanical test report: | if | use: | Seed Coating Machine |

| Marketing Type: | normal product | Voltage: | 220V/380V |

| After Warranty Service: | Video technical support, online support, spare parts, on-site maintenance and repair services | Power (W): | 7KW |

| Spray Gun (PC): | 2 | usage: | agriculture |

| Dimensions (L*W*H): | 1100*700*2500 | brand: | Yuan Sen |

| After-sales service provided: | Provide overseas service center, video technical support | Production capacity (kg/hour): | 10 - 100 |

| Warranty: | 1 year |

Tobacco Seed Coating Machine for Agriculture and Farm

applicationlicense

Mainly used for the processing of granular varieties that require coating.

At present, it can process all kinds of regular or irregular coatings with a core diameter of 0.02~10mm, and the core layer is covered with glue.

The realization process of the coating layer can realize the input of a certain number of core products at one time, and realize the automatic coating process. At present, it is widely used in agricultural seeds, food, chemical industry and other industries.

The quality of automatic coating pills must not only meet the quality standards, but also further improve the appearance, strength, cracking and other indicators.

working principle

After adjusting the spray gun angle and flow rate, start the automatic painting process.

The core is centrifuged at high speed to form an outer loop.

Under the action of the baffle, the iron core turns over and falls on the middle ring and the inner ring.

The binder is sprayed on and combined with the added coating powder to quickly encapsulate the core and coating powder and binder.

During centrifugation, the core and coating powders and binder are subjected to a centrifugation process to densify and form a strong coating. The desired finished particle size is reached after many cycles.

FFood

1. One-time feeding automatically completes the expected granulation size;

2. Ensure core integrity, unity and individual independence;

3. Save core and auxiliary materials, low production cost;

4. Effectively improve the cracking performance;

5. For small and irregular cores, the overall volume can be increased after palletizing, and the shape and size are uniform, which is conducive to mechanized operations.

CStages from original seed to final seed

The first stage - increase the seed size to φ0.9-1.25mm by coating

The second stage - increase the size of the seeds to φ1.6-1.8mm, and get the desired seeds after sieving and dyeing