Tool and Die/Special/Die Alloy Hot Rolled Steel 1.2311 P20 Plastic Mold Steel Plate Price

- $2500.00 / 500 - 4999 pieces

$2000.00 / >=5000 pieces - 500 pieces

- Xingxiong Co., Ltd.

- Guangdong, China

- Mr Jian Liu

| shape: | round/plate/sheet/flat bar | standard: | Aisi |

| thickness: | 20-105MM | payment terms: | L/C, D/P, D/P, T/T |

| application: | Make cold-rolled steel products, make gadgets | customize: | Original Design Manufacturer/Original Equipment Manufacturer |

| Packaging Details: | Wooden box, wooden pallet, anti-rust film, steel wire rope, custom packaging | special: | Cutting tools, measuring tools |

| Supply capacity: | 30000 tons per month | delivery conditions: | Hot Rolled/Hot Forged |

| Available Steel Shapes: | Round rod/plate/square | Alloy or not: | is an alloy |

| Processing services: | punching, cutting | test: | Ut 100% / elemental test |

| technology: | Ef, Ef/Eaf+Lf+Vd, Ef/Eaf+ESR | place of origin; place of origin: | Guangdong, China |

| delivery time: | 31-45 days | our service: | Bandsaw Cutting/Skinning/Grinding |

| brand: | Star | Mode of operation: | Wholesalers and Retailers |

| Package preview: | tolerant: | ±5% | |

| length: | 2500-5000MM | type: | steel plate |

| port: | Shenzhen | width: | 2000-2200MM |

| Certificate: | Japanese standard, ISO9001 | Skin Pass: | Do not |

| an examination: | 100% Ultrasonic According to Test Standard: Se | grade: | carbon alloy steel |

Tool and Die/Special/Die Alloy Hot Rolled Steel 1.2311 P20 Plastic Mold Steel Plate Price

| International steel grade | |||

|

CChina (UK) |

United States (AISI) | Japan (JIS) | Germany (W-NR) |

| 3Cr2MnNi | P20 | FDS3 | 1.2311 |

| CChina (UK) | United States (AISI) | Sweden | Germany (W-NR) |

| 3Cr2MnNiMO | P20+nickel | 718 718ESR | 1.2738 |

| CChina (UK) | United States (AISI) | Japan | - |

| 10Ni3MnCuAl | P21 | NAK80 | - |

| CChina (UK) | United States (AISI) | Germany (W-NR) | - |

| 4Cr13/ 4Cr13R | 420/420ESR | 1.2083/1.2083ESR | |

| CChina (UK) | United States (AISI) | Japan | Germany (WN) |

| 4Cr17NiMo | 168 improvement | G star | 1.2316 |

| CChina (UK) | Japan | - | - |

| 9Cr17NiMo | SUS440C | ||

|

Plastic mold steel is a type of mold steel used in plastic manufacturing. Plastic mold materials are mainly mold steel. The development of die steel has promoted the development of industrial products in the direction of high-grade, diversified, personalized and high added value. All countries in the world include the output of die steel in alloy tool steel, accounting for about 70% to 80% of alloy tool steel.

Plastic mold steel can generally be divided into six categories: age-hardening plastic mold steel (including mirror mold steel), corrosion-resistant plastic mold steel, carburized plastic mold steel, pre-hardened embedded mold steel (including free-cutting steel), tempered Plastic mold steel and quenched plastic mold steel. Widely used age-hardening plastic mold steel, carburized plastic mold steel and pre-hardened plastic mold steel |

|||

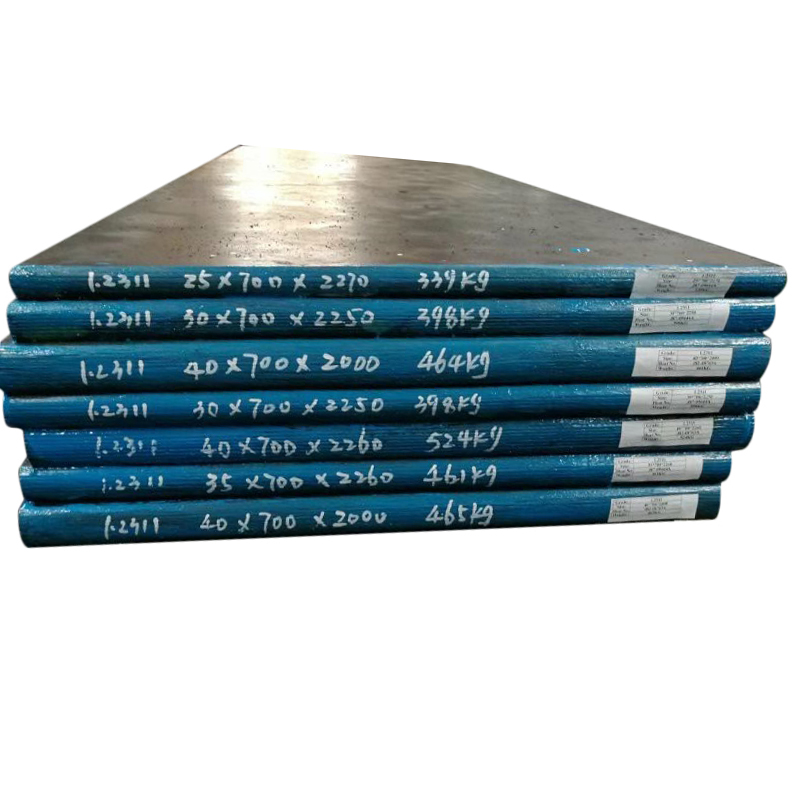

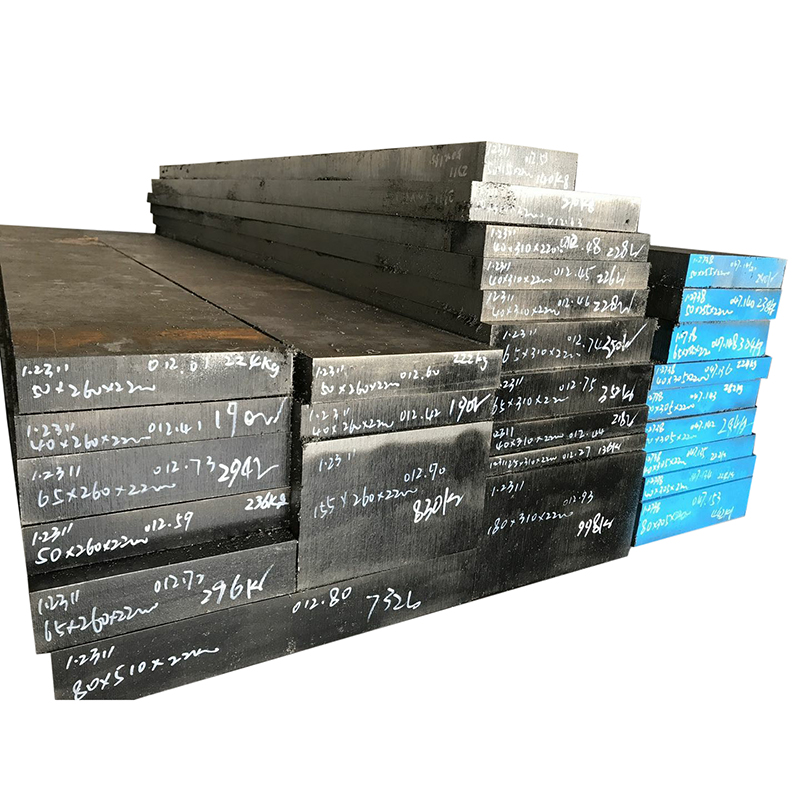

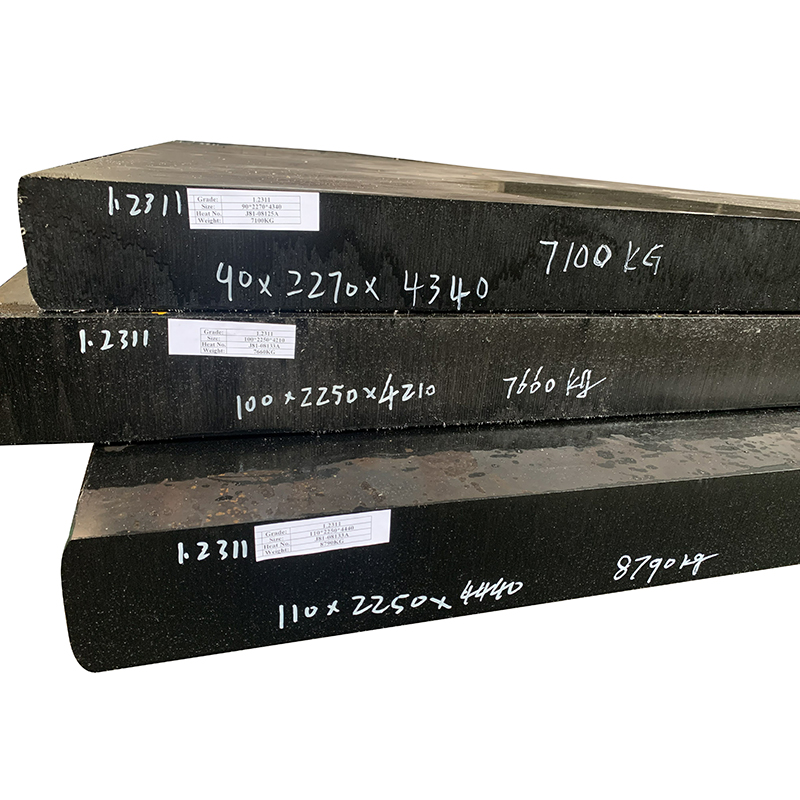

Product display:

| steel grade | chemical composition(%) | |||||||

| C | silicon | manganese | P | small | chromium | mo | you | |

| 1.2311 | 0.35-0.45 | 0.20-0.40 | 1.30-1.60 | ≤0.030 | ≤0.030 | 1.80-2.10 | 0.15-0.25 | - |

| 1.2738 | 0.35-0.45 | 0.20-0.40 | 1.30-1.60 | ≤0.030 | ≤0.030 | 1.80-2.10 | 0.15-0.25 | 0.9-1.20 |

| 718 | 0.35-0.45 | 0.20-0.40 | 0.15-0.25 | ≤0.035 | ≤0.035 | 1.80-2.10 | 0.15-0.25 | 0.90-1.20 |

| NAK80 | 0.33-0.45 | ≤1.00 | 1.00-1.50 | ≤0.030 | ≤0.030 | 15.50-17.50 | 0.80-1.30 | ≤1.00 |

| 1.2316 | 0.33-0.45 | ≤1.00 | 1.00-1.50 | ≤0.030 | ≤0.030 | 15.50-17.50 | 0.80-1.30 | ≤1.00 |

| 1.2312 | 0.35-0.45 | 0.20-0.40 | 1.30-1.60 | ≤0.035 | ≤0.035 | 1.80-2.10 | 0.15-0.25 | - |

| 1.2083 | 0.36-0.45 | ≤1.00 | ≤1.00 | ≤0.030 | ≤0.030 | 12.0-14.0 | - | ≤0.60 |

| Product parameters | |

| product name | AISI P20 steel mold steel price per kg p20 plastic mold steel p20 1.2311 1.2738 1.2312 1.2083 |

| steel grade | p20 1.2311 1.2738 1.2312 |

| Specification |

Round rod: diameter 8mm – 3000mm |

| standard | AIS JIS DIN GB EN |

| customs code | 72283024 72254000 7208511000 |

| forging | Carefully preheat the steel to a maximum of 1150 oC – 1200 oC, maintaining until the temperature is uniform across the cross-section. Do not forge below 850 oC. After the forging operation, the workpiece should cool as slowly as possible. |

| heat treatment | The steel is heated to 800 oC – 850 oC until the temperature is uniform across the cross-section and then cooled in the furnace. |

| hardness | Annealing: ≤220HB Q+T: 28-34HRC heat treatment 55-62HRC |

| application | 1. Develop materials that are easy to process and have good polishing properties |

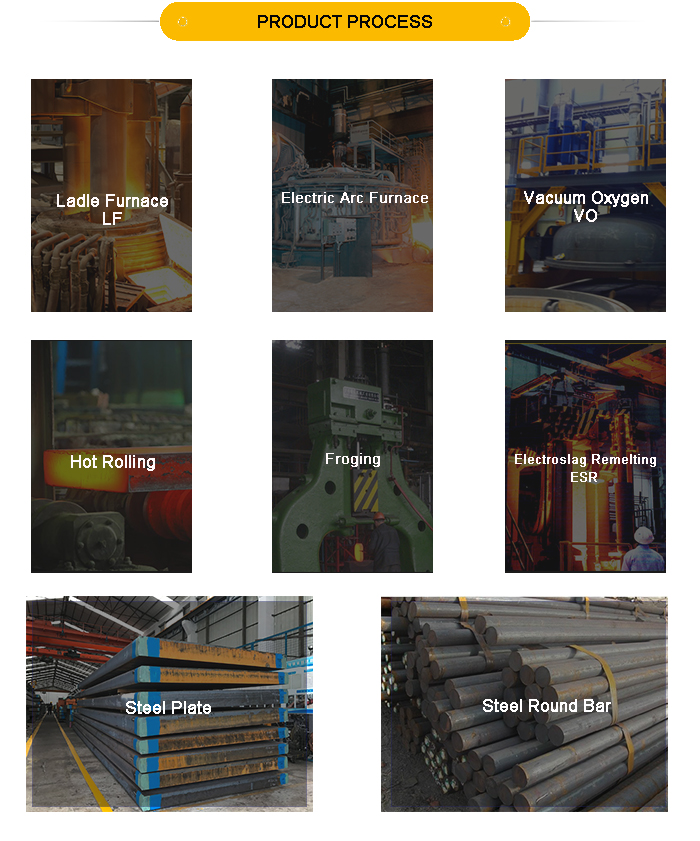

1. Steelmaking: (ladle furnace/electric arc furnace/vacuum oxygen).

2. Steel ingot: (steel ingot rolling/electroslag remelting furnace).

3. Steel round bar: (steel round bar/steel plate).

4. Finished product: (cutting/milling/surfacing/heat treatment/round steel Turing).

Main sales steel grades:

Plastic mold steel: 1.2311, 1.2312, 1.2738, P20, 1.2083, 1.2316, NAK80, P40, 1.2738HH

Hot work die steel: 1.2344, SKD61, H13, H11, FDAC, 8407

Cold world die steel: SKD11, D3, SKS3, 1.2080, 1.2379, CR12MOV, O1, D2

Alloy structural steel: 4140, 20CR, 40Cr, 35CrMo, 42CrMo, 38CrmoAi, SCM440, SCM420, 1.7225

Carbon steel &: Q235, Gcr15, S45C, S50C, S55C

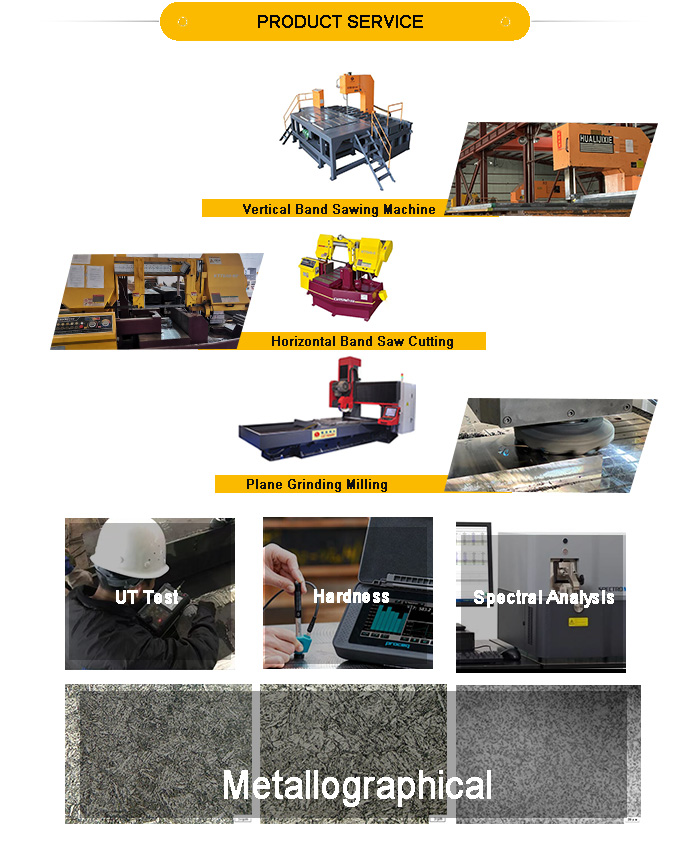

Cutting method: horizontal band saw cutting / vertical band saw

Milling: CNC Surface Grinder, CNC Side Boring Machine, Band Saw,

CNC double-head machine, vertical band saw, CNC milling machine,

Double alloy saw blade, wireless remote control crane, electromagnetic sucker

Inspection: hardness/spectral analysis/ultrasonic testing, etc.