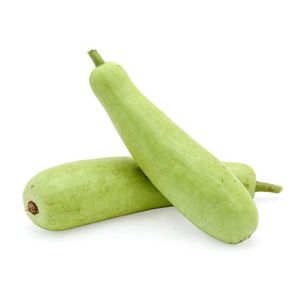

Wholesale Price Vegetable Gourd Seeds Asian Vegetable With Good Packing From Bangladesh

- $0.30 / >=500 pieces

- 500 pieces

- AARYAN APPAREL SOURCING LTD.

- Uttara, China

- Mr Md. Khorshed Alam

PRODUCT DETAIL

| style: | fresh | Packaging Details: | According to customer requirements |

| color: | natural green | Package: | client needs |

| type: | fresh gourd | delivery time: | 7-15 days |

| MOQ: | 1*20 feet | model: | AS-0037 |

| maturity: | 95.0% | pricing term: | FOB |

| usage: | cooking | origin: | Bangladesh |

| pack: | Net weight: 20KG/box | supplying time: | perennial |

| brand: | custom | Origin: | Bangladesh |

| Supply capacity: | 10000 pieces per month | Cultivation type: | Common |

| quality: | upscale | Dimensions (cm): | 10 |

| port: | Chittagong port, air port, any port | Product Category: | other |

| part: | agriculture | color: | green |

| payment terms: | L/C, T/T |

Product Description

Specification

thing | value |

style | fresh |

Product Category | other |

color | green |

Cultivation type | Common |

maturity | 95.0% |

Dimensions (cm) | 10 |

birthplace | Bangladesh |

brand | custom |

model | AS-0037 |

type | fresh gourd |

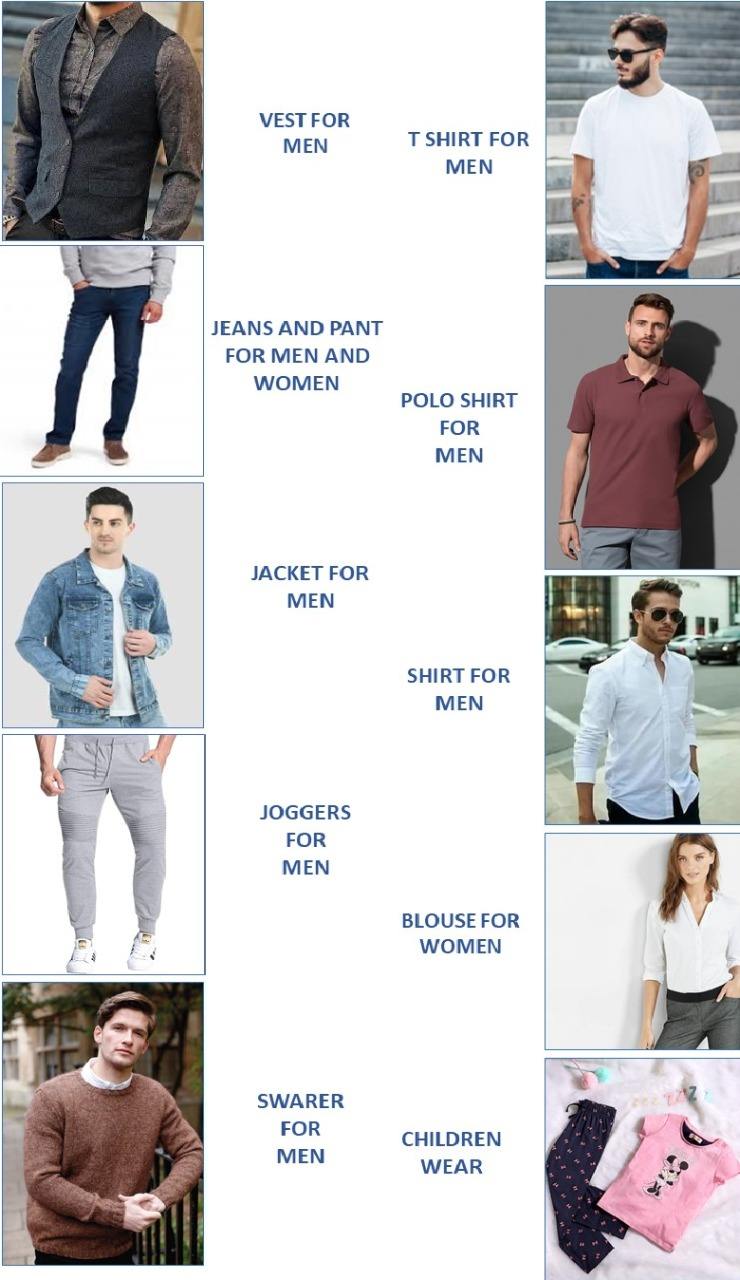

other products

Recommended Products

Company Profile

AARYAN APPAREL SOURCING LTD is a fast growing Apparel Manufacturing, R&D, Sales and Sourcing company from Dhaka, Bangladesh. We develop all businesses in all major productions with multinational brands. Over the years, AARYAN APPAREL SOURCING LTD has become a core manufacturing partner of European and global fashion brands. In addition to our reputation for reliability, our customers recognize our value-added services. Over the years, we have been cooperating with various well-known brands to serve our overseas customers.

all types of sweaters

We work in some well organized factories which are WRAP, BSCI, ISO certified and maintain social compliance standards. The factories are vertically set up with state-of-the-art knitting, dyeing, sewing, automatic printing and embroidery machines, and eminent people have also adopted social responsibility international standards SA8000 and ISO standards. We also evaluate factories based on product range, product quality, production capacity, facilities, financial capabilities, technology orientation, manpower, working conditions, management efficiency and their overall quality policy. Besides our orders, these factories also cooperate with some brand clients, such as; American Eagle, Wal-Mart, S. Oliver, Zara, H&M, C&A, Tesco, Next, Esprit, Marks & Spencer, Target, etc. "Your Trusted Global Sourcing Partner”

The prevention part is covered by our Quality Assurance (QA) team, who develop standards under the guidance of customers

Quality and oversee all elements of pre-production work such as fitting and styling details. the prevention part is

Also supported by an in-house testing laboratory ensuring required testing procedures are performed prior to production

The process begins.

2) control

The control part is under the responsibility of our Quality Control (QC) team, ensuring the product standards set by customers

Cooperate with our QC team throughout the production process, the final product meets our requirements

customer's specification. QC service occurs before the bulk fabric is cut. It consists of the elements listed below.

• Arrival status report of fabrics and necessary accessories.

• Visual control of fabrics: weight/square meter, color, handle, etc.

• Production time forecast (start date, assigned capacity, daily production and completion date).

• Check with Production Supervisor that they believe styles consistent with approved samples are available.

Check category

Normally, our QC will inspect in four stages according to MIL-STD-105E and AATC, ASTM and ISO codes &

standard. The inspection levels adopted for the 4 pre-shipment inspections are as follows:

1. Pre-production inspection (PPC)

2. Initial Production Check (IPC) – Single Sampling Plan General Level I

3. Production Inspection Period (DUPRO) - Single Sampling Plan General Level I

4. Final Random Inspection (FRI) - Single Sampling Plan General Level 2

Design and Development:

Aaryan Apparel Sourcing Ltd" has its own design and proofing department. Designers make designs according to customers' requirements, and they also generate new designs according to current market trends and provide them to customers. We utilize the latest computer-aided systems to develop patterns and marks, To ensure each garment thrives will be an identical replica of the approved sample and the fabrics used to create these garments will be made with as little waste as possible.Trend Discovery: We set up a scouting team and send them overseas to find the latest trends and designs. Once we have a new idea, we work on it. Collection Development: We are constantly working on developing our collections, in which our scouting team plays an important role. They look for the latest trends and we work on designing them set a specific standard and try to add it to our collection. As a result, our collection grows and we can offer more to our customers. Service Improvement: One of our main goals is to keep our customers satisfied, therefore, we are constantly working on To develop our service by providing better quality and bigger collection and customer service.Any complaints or suggestions from customers will be taken very seriously.

sell:

sell:

Good merchandise presentation is the key to the successful execution of customer requirements. Each customer is assigned to a business team that is responsible for ensuring that the customer's requirements are properly understood and executed in close cooperation with the factory. This business team is the main point of contact with the client, and key members of this team travel frequently to the client to improve their understanding of the client's needs and the market. Our merchandisers are experienced professionals and most of them have specific factory experience which enables them to

Understand customer requirements, as well as plant capabilities and limitations. Business teams should contribute to customers, not only in terms of communication and follow-up, but also in making better products that sell well at the point of sale.

Understand customer requirements, as well as plant capabilities and limitations. Business teams should contribute to customers, not only in terms of communication and follow-up, but also in making better products that sell well at the point of sale.

quality:

The process of delivering quality products to our customers is divided into two key areas.

1) Prevention

1) Prevention

The prevention part is covered by our Quality Assurance (QA) team, who develop standards under the guidance of customers

Quality and oversee all elements of pre-production work such as fitting and styling details. the prevention part is

Also supported by an in-house testing laboratory ensuring required testing procedures are performed prior to production

The process begins.

2) control

The control part is under the responsibility of our Quality Control (QC) team, ensuring the product standards set by customers

Cooperate with our QC team throughout the production process, the final product meets our requirements

customer's specification. QC service occurs before the bulk fabric is cut. It consists of the elements listed below.

• Arrival status report of fabrics and necessary accessories.

• Visual control of fabrics: weight/square meter, color, handle, etc.

• Production time forecast (start date, assigned capacity, daily production and completion date).

• Check with Production Supervisor that they believe styles consistent with approved samples are available.

Check category

Normally, our QC will inspect in four stages according to MIL-STD-105E and AATC, ASTM and ISO codes &

standard. The inspection levels adopted for the 4 pre-shipment inspections are as follows:

1. Pre-production inspection (PPC)

2. Initial Production Check (IPC) – Single Sampling Plan General Level I

3. Production Inspection Period (DUPRO) - Single Sampling Plan General Level I

4. Final Random Inspection (FRI) - Single Sampling Plan General Level 2

Our advantage

VIEW MORE

YOU MAY LIKE