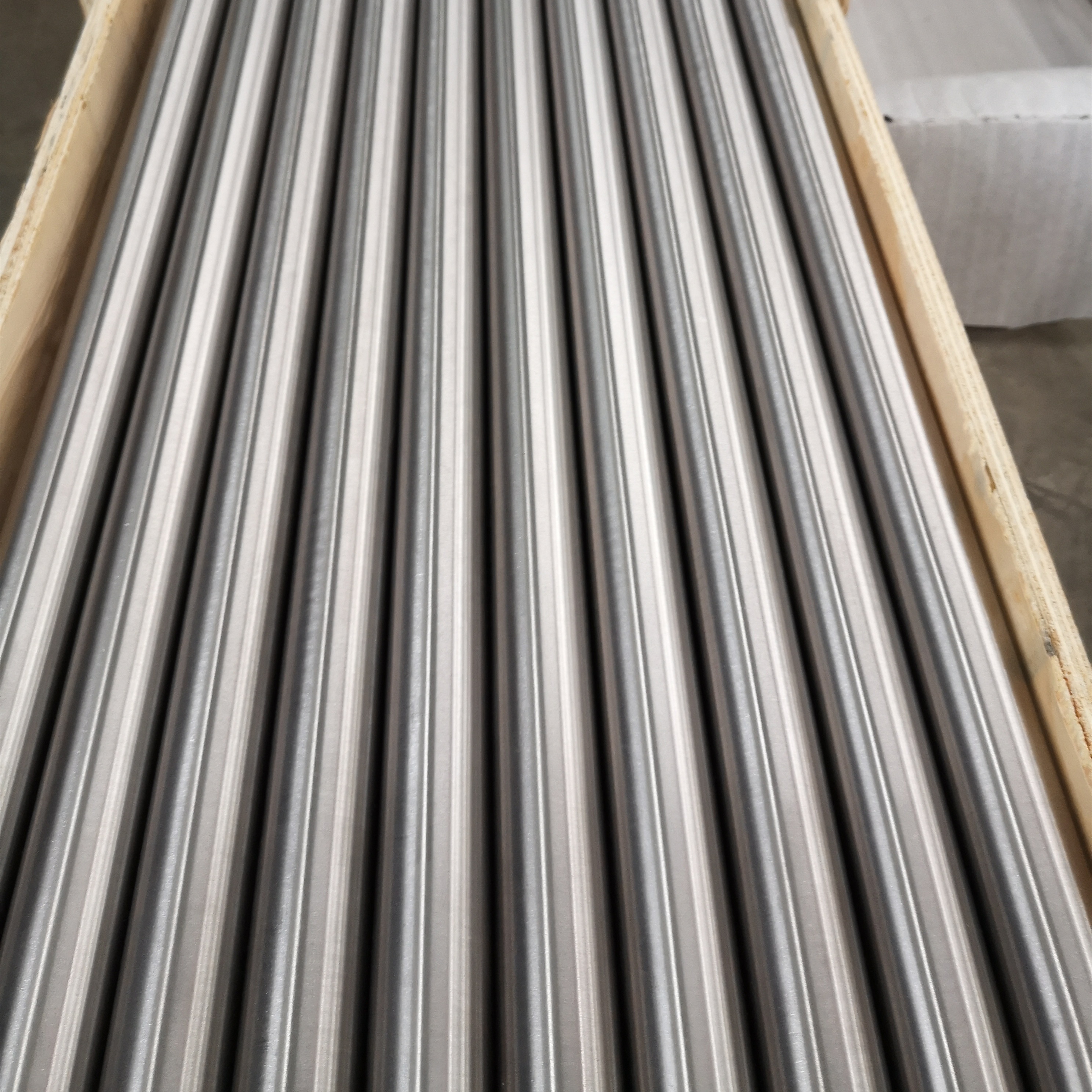

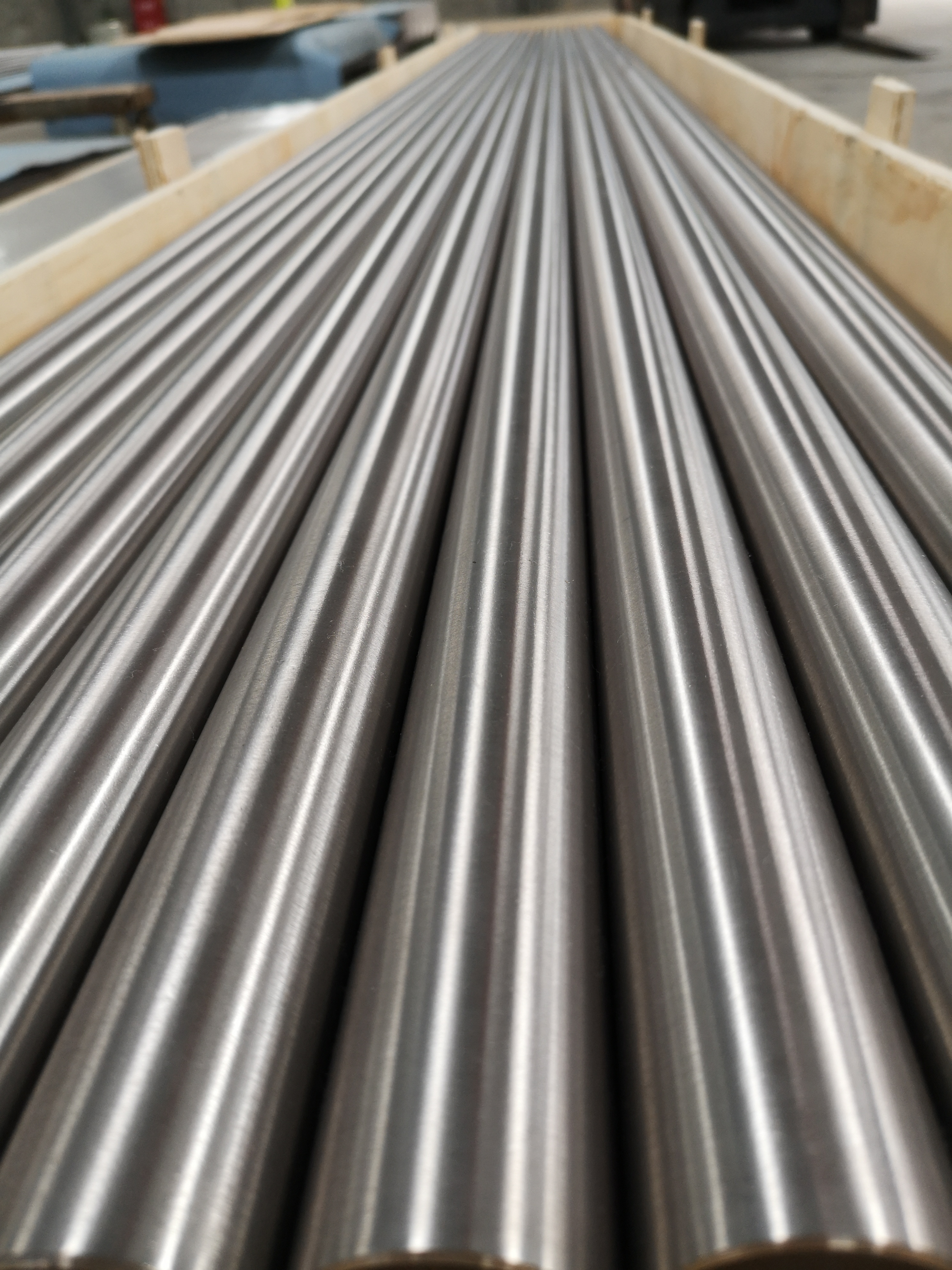

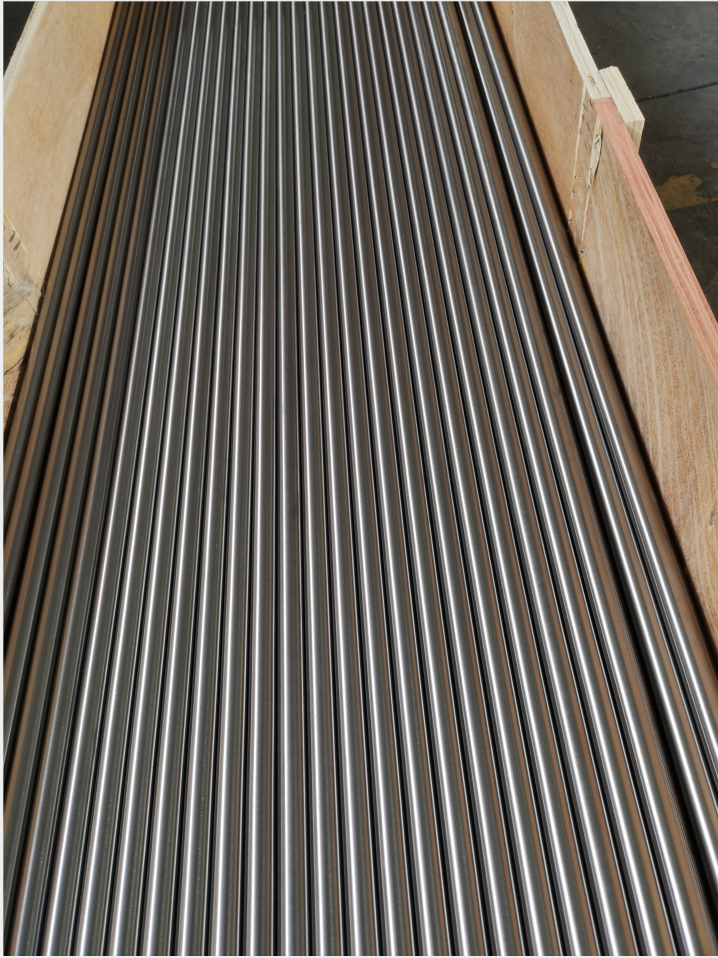

pure titanium rod to produce gr2 pure titanium rod

- $5.00 / >=50 kilograms

- 50 kilograms

- Baoji Qicheng Non-Ferrous Metals Co., Ltd.

- Shaanxi, China

- Mr QCTI DU

PRODUCT DETAIL

| technology: | rolling | grade: | titanium |

| model: | B7001 | place of origin; place of origin: | Shaanxi, China |

| Packaging Details: | Export standard packaging, general three packaging: moisture-proof packaging, anti-collision packaging, export wooden box | Certificate: | ISO9001:2015 |

| Key words: | Gr2 ASTM F67 Medical Titanium Rod | pay: | wire transfer |

| application: | medical | condition: | vacuum annealing |

| MOQ: | 50KGS | Alloy or not: | is an alloy |

| brand: | Administration of Quality Supervision | Supply capacity: | 180 tons per month |

| payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram | Package preview: | |

| Packaging Details: | wooden box | Material: | GR1/GR2/GR3/GR5/GR9/GR12 |

| port: | Tianjin/Shanghai/Ningbo/Shenzhen | Middle school or not: | non-secondary school |

| density: | 4.51 g/cm3 |

quick details

Origin: China Brand Name: QCTI

Model Number: Bar Application: Industrial

Shape: Round Length: 100-6000mm

Process: rolling Material: pure titanium and titanium alloy

Weight: 4.51g Processing method: bending, cutting

Certificate: ISO9001-2015 Surface: Polished surface

Model Number: Bar Application: Industrial

Shape: Round Length: 100-6000mm

Process: rolling Material: pure titanium and titanium alloy

Weight: 4.51g Processing method: bending, cutting

Certificate: ISO9001-2015 Surface: Polished surface

Standard: ASTM348ASTMF136GB/T2965-2007

packaging and delivery

Sales unit: Single

Packing size: 30X20X20 cm

Gross weight per piece: 30.000 kg

Packing type: standard export wooden box

Product Description

Advantages of titanium rods

1.Light weight - [specific gravity] (60% of steel specific gravity, about 1.7 times of aluminum)

2.Low thermal expansion - [coefficient of thermal expansion] (half that of NE-18-8 stainless steel, one third of aluminum)

3.Low hear conductivity-[thermal conductivity] (almost the same as 18-8 stainless steel)

4.Low conductivity-[conductivity](about 3% of copper)

5.High elasticity-longitudinal elastic modulus] (half of iron or stainless steel, same as copper)

6.Non-magnetism -[Magnetic Permeability] (Non-magnetic material; Magnetic Permeability=1.0001)

Titanium is 30% stronger than steel, yet nearly 50% lighter. Titanium is 60% heavier than aluminum, but twice as heavy

sturdy. Titanium has excellent strength retention at 1,000 degrees Fahrenheit. Titanium is alloyed with aluminum, manganese, iron, molybdenum and other metals to increase strength, withstand high temperatures and reduce the weight of the resulting alloy. Titanium's high corrosion resistance is also a valuable property; when exposed to the atmosphere, titanium forms a tight, tough oxide film that is resistant to many corrosive substances, especially salt water.

1.Light weight - [specific gravity] (60% of steel specific gravity, about 1.7 times of aluminum)

2.Low thermal expansion - [coefficient of thermal expansion] (half that of NE-18-8 stainless steel, one third of aluminum)

3.Low hear conductivity-[thermal conductivity] (almost the same as 18-8 stainless steel)

4.Low conductivity-[conductivity](about 3% of copper)

5.High elasticity-longitudinal elastic modulus] (half of iron or stainless steel, same as copper)

6.Non-magnetism -[Magnetic Permeability] (Non-magnetic material; Magnetic Permeability=1.0001)

Titanium is 30% stronger than steel, yet nearly 50% lighter. Titanium is 60% heavier than aluminum, but twice as heavy

sturdy. Titanium has excellent strength retention at 1,000 degrees Fahrenheit. Titanium is alloyed with aluminum, manganese, iron, molybdenum and other metals to increase strength, withstand high temperatures and reduce the weight of the resulting alloy. Titanium's high corrosion resistance is also a valuable property; when exposed to the atmosphere, titanium forms a tight, tough oxide film that is resistant to many corrosive substances, especially salt water.

Material | Pure titanium (GR1, GR2, GR4) Titanium alloy (GR5, GR7, GR9, GR23, Ti-6A-I7Nb Ti-6Al-2Sn-4Zr-2Mo, Ti-6Al-2Sn-4Zr-6Mo Ti-V(15wt%)-Cr(3wt%)-Sn(3wt%)-Al(3wt%) | ||||||

standard | ASTM B348, ASTM 4928 | ||||||

in stock | We have over 80 tons of common size titanium and titanium alloy bars in stock, | ||||||

MOQ | 1 kg in stock | ||||||

delivery time | 1 day 10-15 days when we have stock need production quantity more than 1 ton | ||||||

raw material | We ensure that the raw material is 100% titanium sponge, and we refuse to add any waste | ||||||

Certificate | Provide a 3.1MTC certificate from a third-party testing agency (Bao Titanium Laboratory or Northwest Nonferrous Metals Research Institute) | ||||||

production capacity | About 25 tons per month for bars below OD45mm For bars above OD45mm, about 60 tons per month | ||||||

Normal grade

Tier 1 Titanium is an unalloyed, low-strength titanium product with low oxygen content and high formability; this grade of titanium is used in airframes, heat exchangers and desalination units.Titanium grade 2It is an unalloyed medium strength titanium product. This grade of titanium is used in airframes, aircraft engines, and ship components; good weldability and corrosion resistance are notable features.

Grade III TitaniumIs an unalloyed high-strength titanium product with excellent corrosion resistance and good weldability. This grade of titanium is primarily used in airframe and aircraft engine components.

Titanium Grade IV It is the highest strength pure unalloyed titanium product. This grade of titanium is used almost exclusively in airframes, aircraft engine components, ships, surgical implants, hydraulic tubing. Good formability and corrosion resistance are its hallmarks.

Grade 5 Titanium(6AL-4V) is a titanium alloy product containing 6% aluminum and 4% vanadium; it is a medium-strength product. This grade of titanium is primarily used in airframe and turbine engine parts; and in surgical implants. Technical Information Titanium 6AL – 4V ELI is a titanium alloy product containing 6% Aluminum and 4% Vanadium, ELI (Extra Low Interstitial).

6AL–2Sn–4Zr–2Mo(6-2-4-2) is a titanium alloy product containing 6% aluminum, 2% tin, 4% zirconium and 2% molybdenum.

6AL–6V–2Sn(6-6-2) is a titanium alloy product containing 6% aluminum, 6% vanadium and 2% tin.

5AL–2.5Sn & ELI(5-2.5) is a titanium alloy product containing 5% aluminum and 2.5% tin. There is also ELI (Extra Low Interstitial).

8AL–1V–1Mo(8-1-1) is a titanium alloy product containing 8% aluminum, 1% molybdenum and 1% vanadium.

15V–3Cr–4AL–3Sn(15-3-4-3) is a titanium alloy product containing 15% vanadium, 3% chromium, 4% aluminum and 3% tin.

VIEW MORE