small portable biomass briquetting machine for sale/rice husk biomass briquetting machine

- $2200.00 /set

- 1 set

- Lvsow (Tianjin) International Trade Co., Ltd.

- Henan, China

- Ms Nancy Jiang

PRODUCT DETAIL

| Warranty: | 1.5 years | Video external inspection: | if |

| Production capacity: | 260-280kg/h, 260-340kg/h | Main selling point: | efficient |

| Raw materials: | sawdust | Marketing Type: | normal product |

| Health status: | new | Packaging Details: | Wooden export packing or container loading |

| Showroom location: | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, United Arab Emirates , Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Tajikistan, Japan, Malaysia, Australia | port: | Shanghai/Tianjin/Guangdong/Shenzhen/Qingdao/Lianyungang/Ningbo/Yiwu |

| application: | BBQ (BBQ), heating, BBQ (BBQ), heating | Applicable industries: | Building Materials Store, Manufacturing Plant, Mechanical Repair Shop, Farm, Home Use, Retail, Printing Shop, Construction Works |

| Dimensions (L*W*H): | 1.6m*0.65m*1.4m | product name: | Wood sawdust briquette charcoal machine |

| Voltage: | 380V50hz | manufactures: | Hexagonal biomass wood blocks |

| Core Components Warranty: | 1.5 years | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump | Mechanical test report: | if |

| weight: | 800kg | Supply capacity: | 300 sets per month |

| strength: | 15kw/18.5kw/22kw/30kw | place of origin; place of origin: | Henan, China |

Product Description

The biomass molding machine can be divided into a 50-bar machine and a 70-bar machine according to the size of the molding barrel. The rod making machine is the main equipment for making rod-shaped solid fuel under high pressure and high temperature from wood, rice husk, peanut shell, plant straw and other carbon-containing wood materials (without adding any additives).

Model | motor | capacity | Dimensions (m) | weight |

BR-50A | 15kW | 260-280 kg/h | 1.6*0.65*1.4 | 700kg |

BR-50B | 18.5kW | 300-320 kg/h | 1.7*0.65*1.4 | 800kg |

BR-50C | 22kW | 320-340 kg/h | 1.9*0.7*1.45 | 900kg |

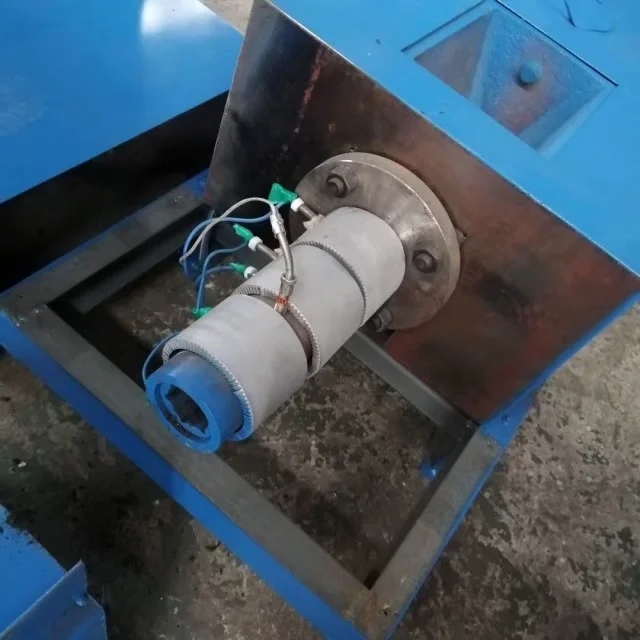

detailed picture

The process flow of wood chip briquetting machine is as follows:

1. Crush the raw materials into small pieces (about 3-5mm in diameter)

2. Machine dry or dry in the sun until moisture is less than 12%

3. Put the material into the feed port of the briquette machine

4. Use biomass raw materials to produce briquette rods without adding any additives

5. Carbonized coal bat fireplace, etc.

2. Machine dry or dry in the sun until moisture is less than 12%

3. Put the material into the feed port of the briquette machine

4. Use biomass raw materials to produce briquette rods without adding any additives

5. Carbonized coal bat fireplace, etc.

Our advantage

1. The machine has the characteristics of reasonable design, reliable manufacturing quality, simple structure and convenient use.

Operation, small size, small footprint, labor-saving and power-saving.

Operation, small size, small footprint, labor-saving and power-saving.

2. The designed automatic control electric heating device can adjust the drying humidity of the material at will, ensure the stability of the material forming, and improve the work efficiency.

3. The main components of this product are specially treated with wear-resistant materials, which can be continuously pressurized and durable.

4. It is suitable for pressing and molding of various biomass raw materials, with low energy consumption and high production efficiency.

5. The heart of the three-bearing old machine is four, which increases the stability and durability of the machine.

6. The old oil-based lubrication is oil-immersed lubrication. As long as there is no shortage of oil, it can be used for many years.

7. Increase the pitch and increase the amount of feed, thereby greatly increasing the output.

8. The structure of the forming cylinder is improved, the friction between the machine and the raw material is reduced, and the density of the mandrel is increased.

VIEW MORE