1000 Liters Liquid Soap, Liquid Fertilizer Tank Mixer

- $5500.00 / 1 - 3 sets

$2000.00 / >=4 sets - 1 set

- Guangzhou Jinghu Mechanical And Electrical Equipment Co., Ltd.

- Guangdong, China

- Ms Ann Lu

| State of health: | new | Spindle speed range (rpm): | 0 - 1400 rpm |

| standard: | International Organization for Standardization | Stirring speed: | 0-1450 rpm |

| Dimensions (L*W*H): | therefore | For merchandise: | Cosmetics, chemicals, beverages |

| Material processing: | Chemicals | Product Category: | Chemical mixing tank |

| Key words: | Mixing tank | Power (kW): | 2.2 kW |

| payment terms: | L/C, Western Union, T/T, MoneyGram | Video shipment inspection: | if |

| way to heat up: | Electric, steam, oil heating | Blender Type: | mixer |

| Mechanical test report: | if | Material: | SUS306/SUS316L, SUS304, SUS316, SUS316L |

| Advantage: | Corrosion resistance | Supply capacity: | 100 sets per month |

| Weight (kg): | 360 kg | Features: | mixed ingredients |

| Warranty: | 1 year | brand: | digital language system |

| Marketing Type: | New Products 2020 | Package preview: | |

| Showroom location: | Malaysia | Main selling points: | multifunctional |

| maximum. Loading volume (L): | 1000 liters | port: | Guangzhou, China |

| Core component warranty: | 1 year | maximum. Loading capacity: | 50000L |

| application: | liquid with suspended solids | place of origin; place of origin: | Guangdong, China |

| Bucket volume (L): | 1100 liters | Applicable industries: | Building materials store, manufacturing plant, machinery repair shop, food and beverage factory, farm |

| Packaging Details: | Wooden box, or according to customer's requirement | Additional features: | Dispersion, mixing, heating, emulsification |

| Core components: | Motor, gearbox, PLC, engine | Surface treatment: | polishing |

| Voltage: | Customize accordingly |

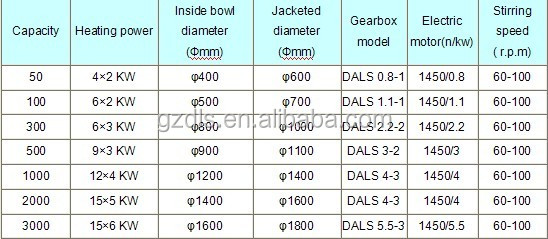

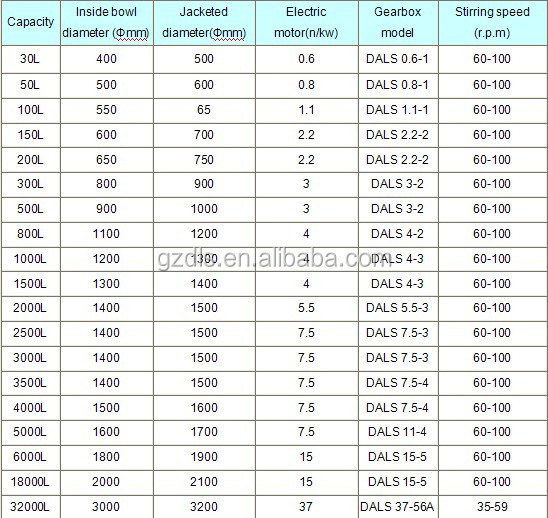

Specification

1. Material: 304(L) 316(L)

2. Surface treatment: mirror or matte; Ra<0.4um

3. Fully comply with GMP requirements

4. According to the process requirements, the tank body can heat/cool the material. Heating methods include steam heating and electric heating.

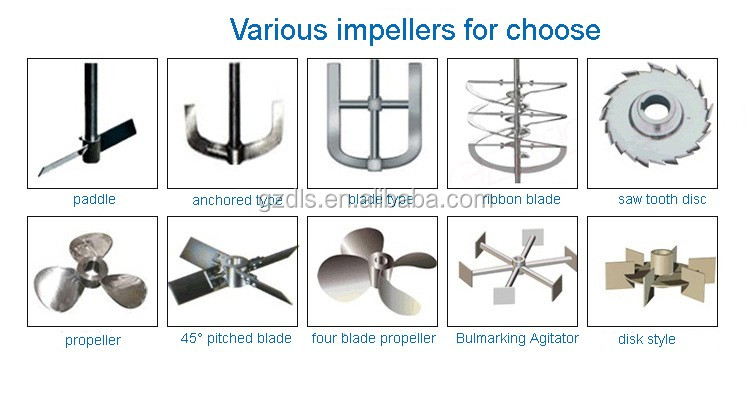

5. Various forms of mixing blades are suitable for the production of different types of products.

6. The discharge is convenient, the bottom discharges directly or the conveying pump discharges.

Advantage

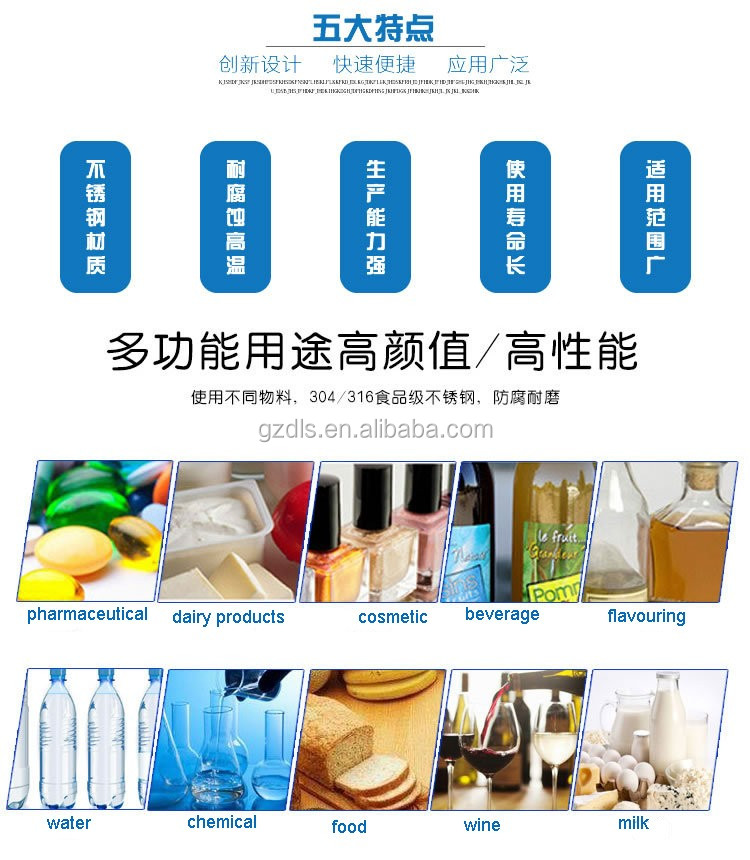

1. Suitable for food, dairy, beverage, pharmaceutical, cosmetic and other industries.

A sort of. Chemical industry: fats, solvents, resins, paints, pigments, oils, etc.

b. Food industry: yogurt, ice cream, cheese, soda, jelly, tomato sauce, oil, syrup, chocolate, etc.

c. Daily chemicals: facial cleanser, hair gel, hair dye, toothpaste, shampoo, shoe polish, etc.

d. Pharmaceuticals: nutrient solutions, Chinese patent medicines, biological products, etc.

2. Our mixer features:

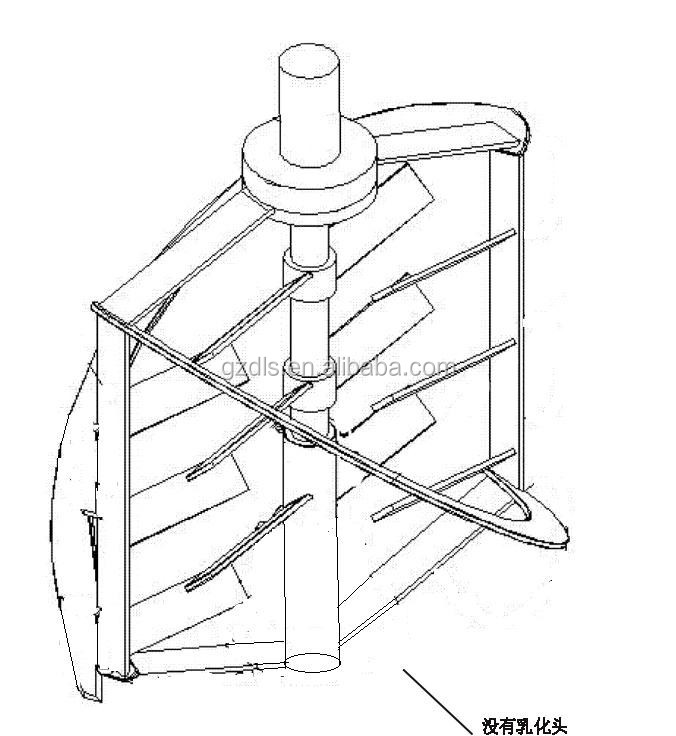

a. The integrated frame design of the mixer is strong and durable.

b. The propeller of the mixer is welded, with high concentricity and stable operation.

c. The tank body of the mixer can be completely stirred by swirling flow, so that the mixing time is shorter.

d. The mixer is made of stainless steel, which is easy to clean and does not rust.

e. It is suitable for mixing machines in various plastic raw materials, feed, powder, chemical industry and other industries.

Reactor equipment is mainly used in the production chains of hydrolysis, neutralization, crystallization, distillation, evaporation, storage, etc. in industries such as medicine, chemical industry, food, and light industry. The reaction kettle is made of SUS304 and SUS316L stainless steel materials. Mixers are divided into anchor type, frame type, paddle type and turbine type, etc. The slewing mechanism can adopt cycloid reducer and stepless reducer. The sealing mechanism can adopt mechanical seal. Heating and cooling can adopt jacket, half pipe, coil and other structures. The heating methods include steam, electric heating, and heat transfer oil, which meet the technological requirements of different working environments such as acid and alkali resistance, high temperature resistance, wear resistance, and corrosion resistance. It can be designed and manufactured according to the customer's process requirements.

Q. Can you do OEM or production as our design?

A. Yes, we can do OEM and customization according to customer requirements.

Q. Are you a manufacturing company or a trading company?

A. We are factory, we have our own engineer team and our own workshop, with more than 11 years OEM experience.

Q. What is your MOQ?

A. 1 piece/set.

Q. What is the payment terms?

A. 30% T/T as advance payment, 70% before shipment, we also accept irrevocable L/C at sight, Western Union, Moneygram.

Q. What's your delivery time?

A. 10-25 days according to your quantity.

Q. Can you send the machine to my sea port?

A. Yes, we can, we accept FOB, C&F, CIF, CIP, by sea and by rail. Our nearest port is Guangzhou.

Q. Do you provide installation and commissioning services?

A. Yes, if it is a single machine, we will send you the installation drawings and documents first, and if you still have questions, we will arrange our engineers to go to your place for installation guidance. If it is a production line, our engineers will go directly to your place to install and debug for you.

Q. Do you provide after-sales service?

A. The warranty period is 2-3 years. If there is any problem caused by unreasonable operation of the equipment within one year, we will help you solve it (if the part is broken, we will send it to you for free; for other minor problems, we will guide you to solve it) by phone or email; if the guidance cannot Solve the problem, arrange technicians to repair after confirmation)

| size | |

| weight | |