1800C premium MoSi2 heating element

- $10.90 /piece

- 1 piece

- Sta Refractory (zhengzhou) Co., Ltd.

- Henan, China

- Ms Alice Wang

| temperature: | 1800C/1700C | Material: | Molybdenum Disilicide |

| type: | U,W,UL,WL | model: | MD-025 |

| Packaging Details: | Wooden case with foam board or according to customer's requirement | brand: | STA |

| Energy source: | electrical | weight: | 2KG |

| Dimensions (L*W*H): | custom made | Heating element: | Molybdenum Disilicide |

| type: | air heater | Supply capacity: | 1,000,000 pieces per month |

| application: | heater parts | port: | Qingdao |

| Warranty: | 6 months, 6 months | Certification: | CE/ISO9001 |

| strength: | 0 | MOQ: | 1 |

| Voltage: | 0 | Origin: | Henan, China |

| Health status: | new | payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| After-sales service provided: | Engineers available to service machinery overseas |

1800C premium MoSi2 heating element

MoSi2 heating element yesResistance heating element made of MoSi2 or base material. Used in high temperature oxidizing atmosphere, the surface is glassy, forming a layer of light SiO2 glass film to protect components from oxidation. Therefore, this element has a unique effect of anti-oxidation at high temperature. The highest temperature for oxidizing atmosphere can reach 1850℃. According to your requirements, our company can produce poles, "U", "W", "U"-right angle, "W"-right angle, special-shaped and other products.

some grades and standard sizes:

1) Main types: U, W, UL, WL, Rod. Material grade: M1700, M1800, M1900.

2) Standard size (mm): 3/6, 4/9, 6/12, 7/14, 9/18, 12/24.

Physical properties of MoSi2 heating element:

| Bulk density | 5.5~5.6g/cm³ | Bending strength | 5.5~25 kg/cm2 |

| Vickers hardness | (High pressure) 570 kg/mm2 | Porosity | 7.4% |

| water absorption | 1.2% | heat ductility | 4% |

Influence of Operating Temperature on Heater Surface under Different Atmospheres

atmosphere | Component maximum operating temperature | ||

1700 level | 1800 level | 1900 class | |

NO2, CO2, O2, air | 1700°C | 1800°C | 1850°C |

Helium, Argon, Neon | 1650°C | 1750°C | 1800°C |

sulfur dioxide | 1600℃ | 1700°C | 1800°C |

carbon monoxide, hydrogen | 1500℃ | 1600℃ | 1700°C |

Wet H2 | 1400°C | 1500℃ | 1650°C |

dry hydrogen | 1350°C | 1450°C | 1600℃ |

The main purpose of the heating element:

Widely used in sintering and heat treatment of ceramics, magnets, glass, metallurgy, refractories, etc.

Please Note: Dimensions: MoSi2 Heating Element:

Hot zone diameter (D1): mm

Cold end diameter (D2): mm

Hot zone length(Le):mm

Cold end length (Lu):mm Shank distance (A):mm

For example:

D1=6mm, D2=12mm, Le=190mm, Lu=200mm, A=50mm

Please specify as: dia6/12x190x200x50mm (D1/D2 x Le x Lu x A mm)

MoSi2 heating element picture:

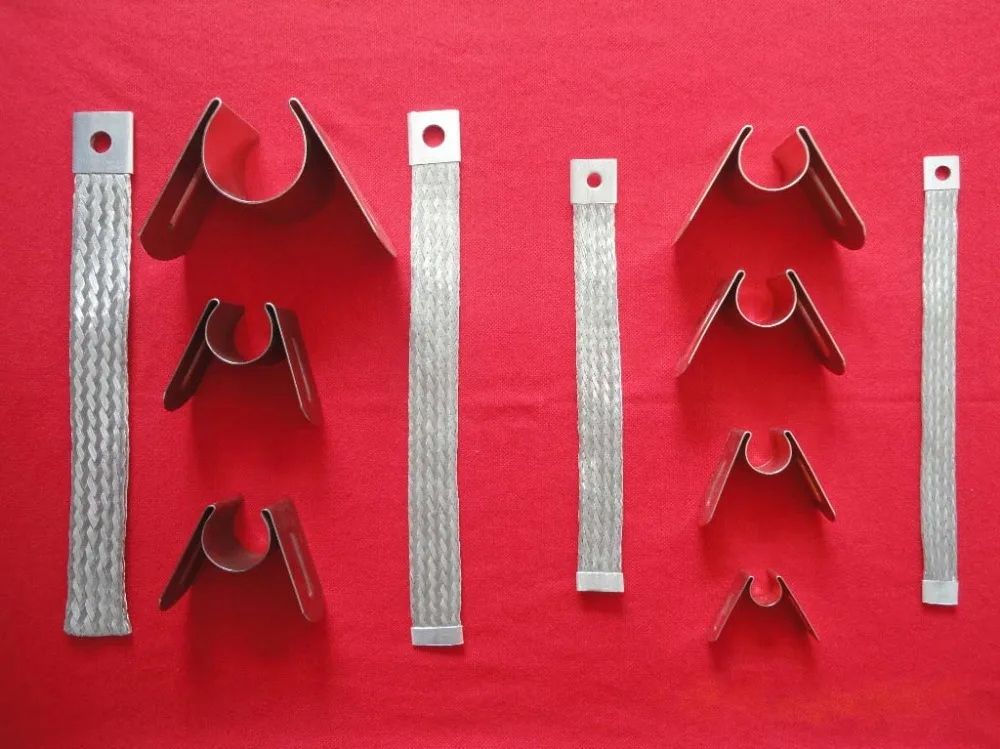

Clips and Straps:

Shipping terms: DHL/FEDEX/TNT EXPRESS

Package: