2 in 1 All Sizes Various Packaging 2D TPU Sublimation Blank Phone Case for iphone 6 7 8 x 12 13 DIY with Sublimation Coating

- $0.60 / 200 - 999 pieces

$0.45 / 1000 - 2999 pieces

$0.40 / 3000 - 9999 pieces

$0.30 / >=10000 pieces - 200 pieces

- Dongguan Wish Packaging Technology Co., Ltd.

- Jiangsu, China

- Mr Vivian Hong

PRODUCT DETAIL

| Serve: | OEM ODM support | Dimensions (L*W*H): | 230 x 91 x 160 cm |

| size: | custom size | product name: | Sublimation Blank Phone Case |

| Colors and Pages: | Polychromatic | Health status: | new |

| color: | black/white/transparent | type: | Hot Press |

| Core component warranty: | other | Plate type: | Sublimation heat transfer printing |

| Package: | OPP bag + carton | Mechanical test report: | not available |

| Video shipment inspection: | not available | weight: | 0.1 kg |

| Driver type: | manual | Packaging Details: | opp bag/carton+outer carton |

| sample: | free of charge | Warranty: | other |

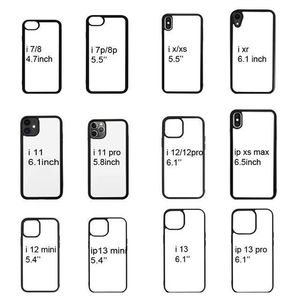

| Automatic level: | semi-automatic | application: | Sublimation for Iphone 6/7/8/X/XR/11/12/13 pro max |

| Main selling points: | easy to operate | Applicable industries: | home use, printing factory |

| Voltage: | 220V/380/440V | Core components: | other |

| brand: | hope | Platen size: | 38*38cm |

| delivery time: | 3-15 days | port: | Shanghai |

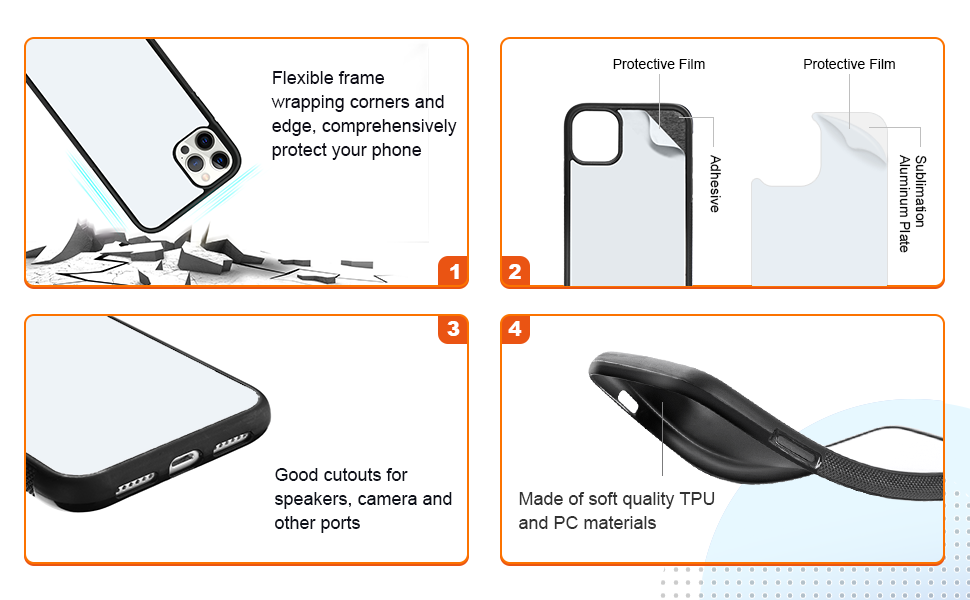

| Material: | Aluminum+TPU+PC | usage: | thermal transfer |

| Supply capacity: | 500,000 volumes per month | Origin: | Guangdong, China |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram, Paypal |

Product Description

Product Category: | Sublimation Blank Phone Case |

Material: | PC/TPU shell + sublimation aluminum plate |

appropriate types: | full range of iphones |

color | black, white, transparent or customized |

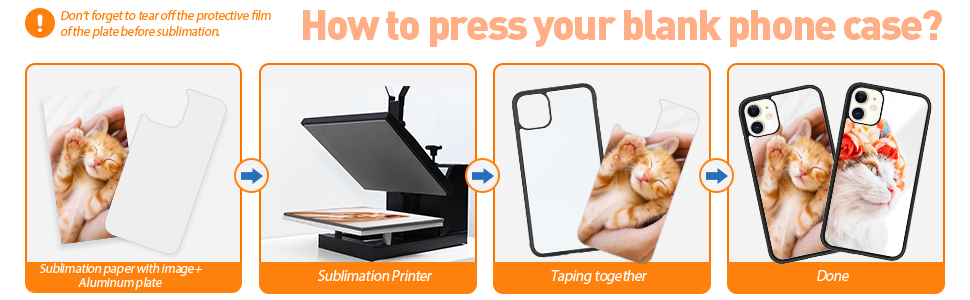

temperature: | 170-175°C (340-350°F) |

time: | 45-60 seconds |

sample | free of charge |

1. What is dye sublimation transfer printingDye-sublimation transfer printing is to use an inkjet printer equipped with thermal transfer ink to print images such as portraits, landscapes, and text on the dye-sublimation transfer paper in a mirror-reversed manner, and then heat it to about 200°C. Thermal transfer equipment. The thermal transfer ink on the sublimation paper will penetrate into the substrate in the form of gasification, so as to transfer the image color on the paper to the new technology of textiles, porcelain cups, porcelain plates, porcelain plates, metal and other materials.2. Printers suitable for our productsOrdinary inkjet printers: Epson C65, 830u, R210, R310, R800, 1520k, EX3, 1290, 2100, Lenovo: cj100 and other wide-format inkjet printers: Epson 3000, 4000, 4000hs, 7600, 9600, 10600; Roland, Mutoh , ENCAD, Mimaki, etc.3. Sublimation transfer ink to be usedDye-sublimation transfer ink must be used. This ink, made from disperse dyes, sublimes and dyes with the substrate at transfer temperatures. High-quality dye-sublimation ink does not block the nozzle, the color is vivid, and the stability is good.4. Adjust the appropriate color densityAdjust the color density in the computer to avoid over-inking. After adjustment, you need to check the thermal transfer effect.5. Adjust the appropriate hot pressing temperature and timeThe thermal transfer temperature range is about 180-230°C, and the time is about 10-30 seconds. Before the formal batch transfer, a small test should be carried out to determine the process parameters.6. When thermal transfer printing, the hot pressing surfaces must be close to each otherDuring heat transfer printing, the heat press surface, transfer paper and the surface of the substrate must be in close contact without gaps, otherwise the transfer image will be blurred.Seven, the advantages of sublimation transfer printingThe graphics and texts of sublimation transfer printing are bright and rich in color, and its effect is comparable to that of printing. Sublimation transfer printing is to sublimate the thermal transfer ink to the object at high temperature, and form a color image after sublimation. Therefore, the heat transfer product is durable and the image will not peel off, crack and fade.

VIEW MORE

YOU MAY LIKE