2021 New low-cost vacuum forced circulation evaporator for ammonium sulfate crystallization

- $12000.00 /set

- 1 set

- VANOO (SHANGHAI) MACHINERY EQUIPMENT CO.,LTD

- Shanghai, China

- Ms Antonia Shu

PRODUCT DETAIL

| Mechanical test report: | if | Local service location: | not any |

| Core Components Warranty: | 1 year | Type of machine: | multifunctional |

| Video external inspection: | if | Controller: | programmable logic controller |

| Supply capacity: | 10 sets per month | weight: | custom made |

| Voltage: | custom made | Health status: | new |

| Warranty: | 1 year | Applicable industries: | Manufacturing plants, energy and mining, chemical industry |

| After-sales service provided: | Free spare parts, on-site installation and commissioning training, on-site maintenance and repair services, video technical support, online support | strength: | custom made |

| Certification: | CE/ISO | Dimensions (L*W*H): | custom made |

| Marketing Type: | New Products 2020 | Product Category: | Zinc sulfate |

| place of origin; place of origin: | China Shanghai | type: | Evaporator |

| Packaging Preview: | Name: | Ammonium sulfate production forced circulation crystallizer | |

| Packaging Details: | We usually put the machines in containers with soft clothes, some in wooden boxes, and most importantly some control systems we take care and put in boxes. | Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump |

| After Warranty Service: | Video technical support, online support, spare parts, on-site maintenance and repair services | temperature range: | 0 - 280 degrees |

| brand: | Vanno (Shanghai) | port: | Shanghai/Ningbo Port |

| payment terms: | Letter of Credit, T/T, Western Union, MoneyGram | Main selling point: | Famous brand PLC |

| Showroom location: | not any |

product description

China factory low-cost high-efficiency laboratory multi-effect MVR evaporator

*

The forced circulation evaporator, also known as the FC evaporator, transports the material to the tubular heater through a large flow circulation pump. The heated material enters the separator for evaporation and separation. The unevaporated liquid material is transported by the circulating pump to the heater to be heated and evaporated again, forming a process of repeated circulation and evaporation. It is suitable for the treatment of scaling, crystallization, heat-sensitive (low temperature), high concentration, high viscosity and insoluble solid materials with particles. It is an ideal equipment for concentrating heat-sensitive materials such as fruit pulp (tomato paste), inorganic salts (ammonium sulfate, sodium sulfate, sodium chloride, etc.), malt and essence, starch syrup, sugar, oligosaccharide, inositol, protein, etc. heat sensitive material. It is widely used in the evaporation and concentration of water phase or organic phase solution in food, medicine, chemical industry, environmental protection and other industries.

MVR

1. Energy saving: high thermal efficiency, energy saving and electricity saving, low energy consumption, energy consumption for evaporating 1t of water

About 1/5 to 1/3 of the traditional evaporator.

2. Environmental protection: completely get rid of the dependence on steam boilers, mechanical steam recompression evaporator

Electric start.

3. No boiler, no need to burn coal, a small amount of steam, a small amount of cooling water.

Low operating cost: Due to low energy consumption, the operating cost of the entire evaporator is only 1/3~1/2

traditional evaporator.

4. Small footprint: The system has a high-density mechanical structure, and its footprint is less than 50% of that of traditional evaporators.

5. Mild evaporation: low temperature evaporation, small heat transfer temperature difference, the system is not easy

scale.

6. High degree of automation: high degree of automation, simple operation and convenient operation.

feature

1. Alcohol recovery: the recovery amount is large, and the vacuum concentration process is adopted. The production efficiency is increased by 5-10 times compared with the old similar equipment, and the energy consumption is reduced by 30%. It has the characteristics of small investment and high recovery efficiency.

2. Concentration: This equipment adopts external heating natural circulation, vacuum negative pressure evaporation, and evaporation is fast. The concentration ratio can reach 1.2. The liquid is completely sealed and no foam concentrates. The equipment concentrate has the characteristics of non-polluting, rich taste and easy cleaning. The device is easy to operate and occupies a small area. The heater and evaporator are made of insulating layer, the inner surface is mirror polished, and the surface is matt.

structure and performance

1. The equipment consists of heating chamber, separator, defoamer, steam separator, condenser, cooler, liquid storage tank,

Circulation pipes and other components. The whole set of equipment is made of high-quality stainless steel.

2. The interior of the heating chamber is a column tube type. After the shell is connected to the steam, the liquid in the shell

Heat the column. The chamber is also equipped with pressure gauges and safety valves to ensure production safety.

3. There is a sight glass at the front of the separation chamber for the operator to observe the liquid condition

evaporation. The rear manhole is convenient for cleaning when changing varieties. Equipped with a thermometer and a vacuum gauge, you can observe and master the temperature of the liquid in the evaporation chamber and the degree of vacuum during evaporation under pressure.

About 1/5 to 1/3 of the traditional evaporator.

2. Environmental protection: completely get rid of the dependence on steam boilers, mechanical steam recompression evaporator

Electric start.

3. No boiler, no need to burn coal, a small amount of steam, a small amount of cooling water.

Low operating cost: Due to low energy consumption, the operating cost of the entire evaporator is only 1/3~1/2

traditional evaporator.

4. Small footprint: The system has a high-density mechanical structure, and its footprint is less than 50% of that of traditional evaporators.

5. Mild evaporation: low temperature evaporation, small heat transfer temperature difference, the system is not easy

scale.

6. High degree of automation: high degree of automation, simple operation and convenient operation.

usage

This machine is used for the concentration of traditional Chinese medicine, western medicine, starch sugar food, dairy products, etc. It is especially suitable for low temperature vacuum concentration of heat-sensitive materials.feature

1. Alcohol recovery: the recovery amount is large, and the vacuum concentration process is adopted. The production efficiency is increased by 5-10 times compared with the old similar equipment, and the energy consumption is reduced by 30%. It has the characteristics of small investment and high recovery efficiency.

2. Concentration: This equipment adopts external heating natural circulation, vacuum negative pressure evaporation, and evaporation is fast. The concentration ratio can reach 1.2. The liquid is completely sealed and no foam concentrates. The equipment concentrate has the characteristics of non-polluting, rich taste and easy cleaning. The device is easy to operate and occupies a small area. The heater and evaporator are made of insulating layer, the inner surface is mirror polished, and the surface is matt.

structure and performance

1. The equipment consists of heating chamber, separator, defoamer, steam separator, condenser, cooler, liquid storage tank,

Circulation pipes and other components. The whole set of equipment is made of high-quality stainless steel.

2. The interior of the heating chamber is a column tube type. After the shell is connected to the steam, the liquid in the shell

Heat the column. The chamber is also equipped with pressure gauges and safety valves to ensure production safety.

3. There is a sight glass at the front of the separation chamber for the operator to observe the liquid condition

evaporation. The rear manhole is convenient for cleaning when changing varieties. Equipped with a thermometer and a vacuum gauge, you can observe and master the temperature of the liquid in the evaporation chamber and the degree of vacuum during evaporation under pressure.

Function list

The whole set of equipment mainly consists of heater, separator, circulation pipe, vapor-liquid separator, surface condenser, vacuum pump, feed pump, discharge pump, forced circulation pump, condensate pump, electric control box, workbench and all pipelines, Valve composition and instrumentation.

Mold structure diagram

Machine display

Front view

Product Specifications

Model | VOFC-01 | VOFC-02 | VOFC-03 | VOFC-04 | ||||

Water evaporation (t/h) | 0.1-2 | 0.5-10 | 2-20 | 5-50 | ||||

Enter the concentration | We will design according to different kinds of raw materials | |||||||

(MPa) steam pressure | 0.4-0.8 | |||||||

steam consumption (with heat pump) | 0.65 | 0.38 | 0.28 | 0.18 | ||||

(MPa) maximum vacuum | -(0.030~0.090) | |||||||

Evaporation temperature | 45-90 | |||||||

Cooling water cost/evaporation | 2-40 | 7.5-150 | 25-250 | 50-500 | ||||

Note: We can design and manufacture according to the special requirements of customers. | ||||||||

Product configuration

Features of MVR Evaporator:

1. Energy saving: high thermal efficiency, energy saving and electricity saving, low energy consumption, energy consumption for evaporating 1t of water

About 1/5 to 1/3 of the traditional evaporator.

2. Environmental protection: completely get rid of the dependence on steam boilers, mechanical steam recompression evaporator

Electric start.

3. No boiler, no need to burn coal, a small amount of steam, a small amount of cooling water.

Low operating cost: Due to low energy consumption, the operating cost of the entire evaporator is only 1/3~1/2

traditional evaporator.

4. Small footprint: The system has a high-density mechanical structure, and its footprint is less than 50% of that of traditional evaporators.

5. Mild evaporation: low temperature evaporation, small heat transfer temperature difference, the system is not easy

scale.

6. High degree of automation: high degree of automation, simple operation and convenient operation.

About 1/5 to 1/3 of the traditional evaporator.

2. Environmental protection: completely get rid of the dependence on steam boilers, mechanical steam recompression evaporator

Electric start.

3. No boiler, no need to burn coal, a small amount of steam, a small amount of cooling water.

Low operating cost: Due to low energy consumption, the operating cost of the entire evaporator is only 1/3~1/2

traditional evaporator.

4. Small footprint: The system has a high-density mechanical structure, and its footprint is less than 50% of that of traditional evaporators.

5. Mild evaporation: low temperature evaporation, small heat transfer temperature difference, the system is not easy

scale.

6. High degree of automation: high degree of automation, simple operation and convenient operation.

Shanghai Sewage Treatment

Machine display

Shanghai customer factory

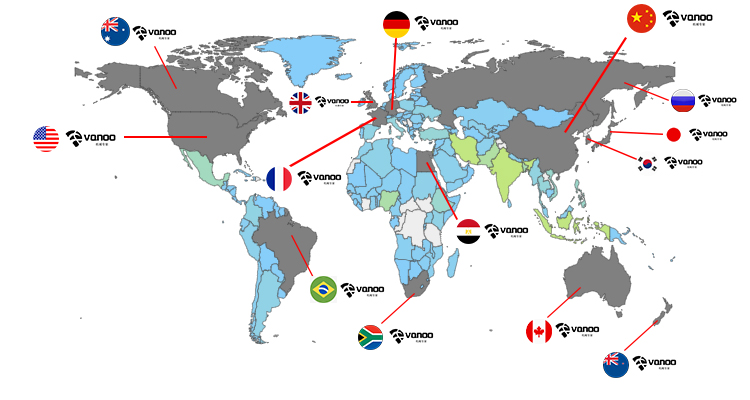

Sales and Service Network

successful project

Thailand project

Shanghai project

Russian project

VIEW MORE

YOU MAY LIKE

Other Products

-

sesame oil distillation machine fish oil distillation machine film molecular distillation$12000.00 / set

sesame oil distillation machine fish oil distillation machine film molecular distillation$12000.00 / set -

High-efficiency and energy-saving citrus/lemon juice processing line$90890.00 / set

High-efficiency and energy-saving citrus/lemon juice processing line$90890.00 / set -

2021 High efficiency Industrial apple juice processing machine from Shanghai$88000.00 / set

2021 High efficiency Industrial apple juice processing machine from Shanghai$88000.00 / set -

4000LPH milk & whey evaporator -Triple effect falling film evaporator with high efficiency$23000.00 / set

4000LPH milk & whey evaporator -Triple effect falling film evaporator with high efficiency$23000.00 / set