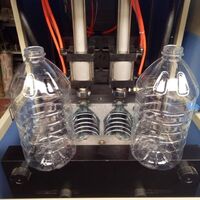

3L Semi-Automatic Plastic PET Drinking Water Bottle Blow Molding Machine Stretch Blow Molding Machine

- $3000.00 /set

- 1 set

- Taizhou Shunke Moulding Co., Ltd.

- Zhejiang, China

- Mr Wayne Zheng

PRODUCT DETAIL

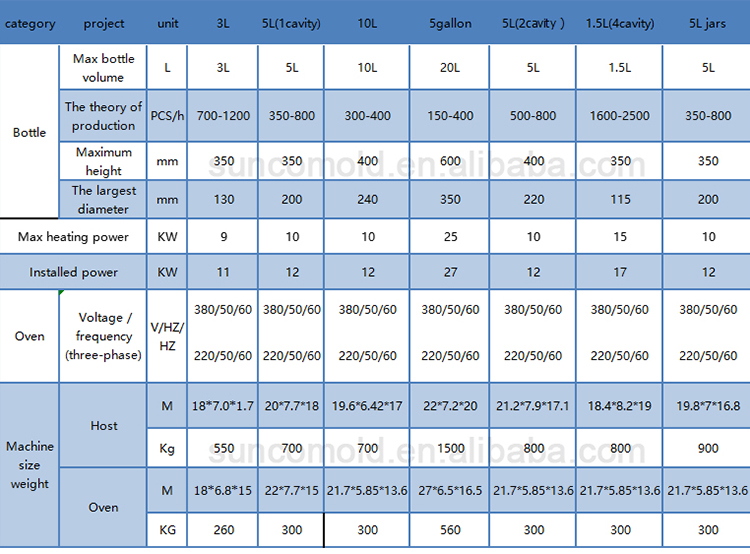

| Supply capacity: | 100 tons per month | Preheater heating zone: | 4 heating zones |

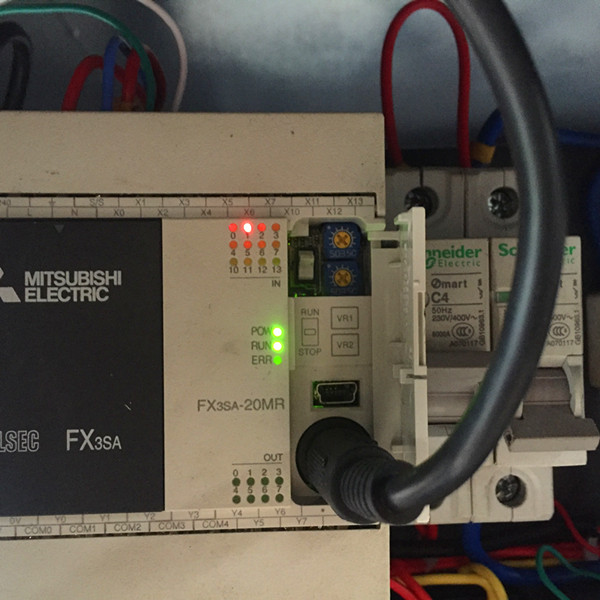

| Neck Diameter (mm): | 45 mm | PLC brand: | Siemens, Mitsubishi, Delta, etc. |

| Dimensions (L*W*H): | Host: 18*7.0*1.7m/Oven: 18*6.8*15m | Weight (kg): | 810 kg |

| Warranty: | 1 year | brand: | shunko |

| Maximum bottle diameter (mm): | 130mm | Health status: | new |

| After-sales service provided: | Video Technical Support | port: | Ningbo/Shanghai |

| Power (kW): | 11 | Applicable industries: | Food and Beverage Factory |

| Maximum bottle height (mm): | 350mm | payment terms: | L/C, Western Union, T/T, MoneyGram |

| Core components: | Motor, PLC | Origin: | China |

| Mechanical test report: | if | Packaging Details: | Plastic bottle blow molding machine packaging: first apply anti-rust oil, then apply plastic waterproof film, and finally pack in standard plywood box/fumigation wooden box for export. Spare parts are shipped together with the machine |

| Package preview: | automation: | semi-automatic | |

| High pressure valve brand: | Parker | Blow molding machine material: | steel |

| Blow molding machine valve: | High pressure blow valve and low pressure shift valve | Video outbound inspection: | if |

| Core component warranty: | 1 year | Bottle capacity (ml): | 3000ml |

| Certification: | CE/ISO9001:2008 | Blow molding machine paint color: | Customized/Blue/Green/Black etc. |

| Blow molding machine processing: | Milling/drilling/polishing/lathe/flying knife etc. | Main selling points: | easy to operate |

| Voltage: | 220V/380V | After Warranty Service: | Spare Parts/Online Support |

| Hollow part volume: | ≤3L | Year: | by production date |

| application: | Using air pressure to blow the preform into a bottle, the bottle | Plastic processing: | Polyester, polycarbonate, polypropylene |

detailed picture

Semi-automatic blow molding machines for plastic bottles up to 3 liters:

Product Description

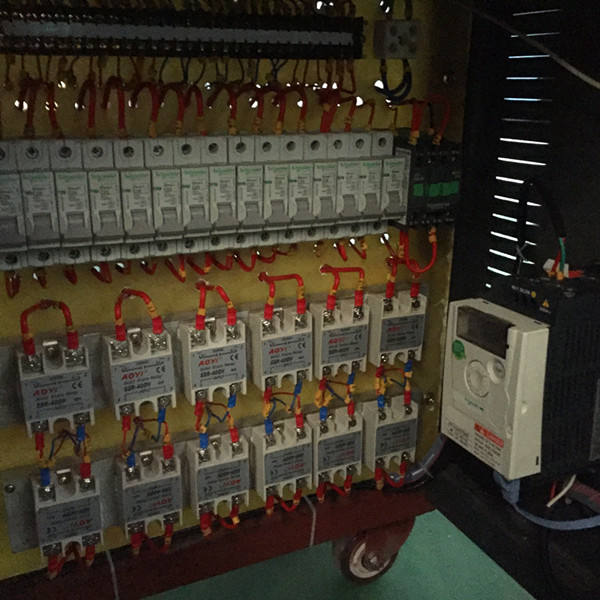

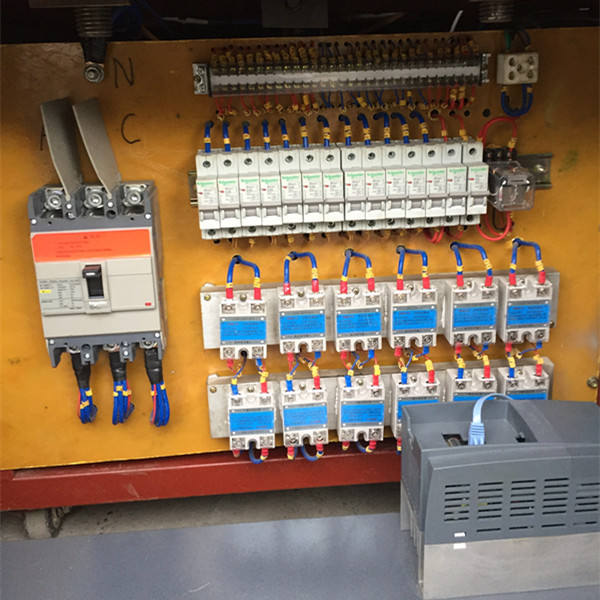

Main components of semi-automatic bottle blowing machine: | ||||

Pneumatic part | valve | SMC/PARK/FESTO/Airtac etc. | ||

cylinder | ||||

Electrical parts | PLC | Mitsubishi/Siemens/Delta etc. | ||

operating system | Mitsubishi/Siemens/Delta etc. | |||

contactor | Schneider | |||

relay | Omron | |||

Infrared Thermometer | Retech | |||

notes | All electrical components are certified by CE\UL\CCC International advanced high-tech products. | |||

Semi-automatic blow molding machine performance:

1. Using advanced PLC, the performance is stable.

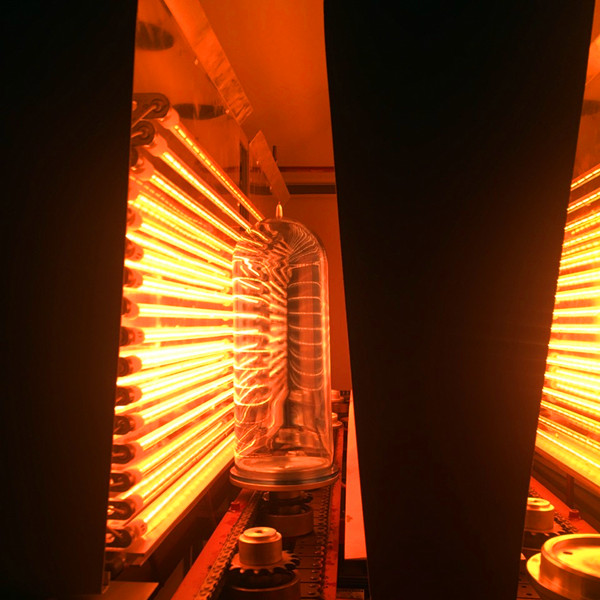

2. Strong penetrating power, through the rotation and revolution of the bottle, the heat distribution is good and rapid.

The rails are in the infrared preheater at the same time.

3. Strong adjustability. By adjusting the lamp tube and the length of the lamp tube, the preheater can preheat the shape of the preform.

The preheating area is equipped with a reflective plate, and the preheater is equipped with an automatic constant temperature device to keep the temperature constant.

4. High safety. Each mechanical action is equipped with a safety automatic locking device. In case of a failure in a certain process, the process can enter a safe state.

5. The cylinder is used instead of the oil pump to drive the action, no pollution and low noise.

6. Divide the blowing and action in the air pressure diagram of the machine into three parts to meet the blowing and mechanical actions of different air pressures.

7. Strong clamping force, high pressure, double crank connecting rod clamping.

8. Operation mode: manual.

9. Safe and reliable, the unique valve position design makes the air pressure diagram of the machine easier to understand.

10. Low cost, high efficiency, simple operation, convenient maintenance, etc.

11. Avoid bottle contamination.

12. The cooling effect of the bottle mold cooling system is ideal.

13. Easy to install and start.

14. Low rejection rate: less than 0.2%.

15. Save labor, one person can operate the machine.

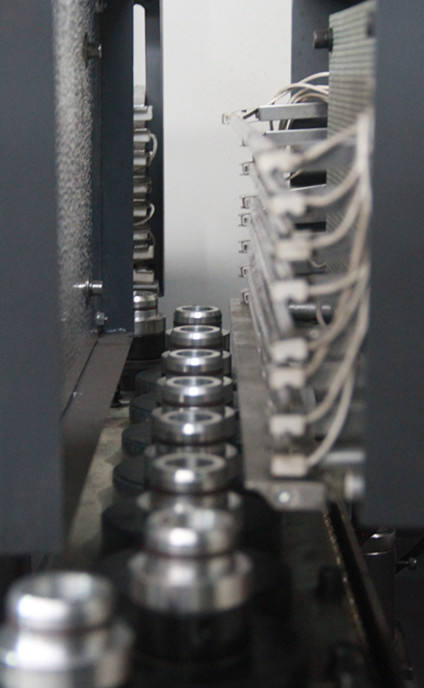

16. Adopt a new double curved arm and four-bar clamping structure (patented): horizontal; the middle template moves in parallel; the distance between the two templates is adjusted by the sprocket. Therefore, the clamping force is very strong.

17. Power-saving design, can increase your profit.

18. Separate air control system to avoid waste pollution.

2. Strong penetrating power, through the rotation and revolution of the bottle, the heat distribution is good and rapid.

The rails are in the infrared preheater at the same time.

3. Strong adjustability. By adjusting the lamp tube and the length of the lamp tube, the preheater can preheat the shape of the preform.

The preheating area is equipped with a reflective plate, and the preheater is equipped with an automatic constant temperature device to keep the temperature constant.

4. High safety. Each mechanical action is equipped with a safety automatic locking device. In case of a failure in a certain process, the process can enter a safe state.

5. The cylinder is used instead of the oil pump to drive the action, no pollution and low noise.

6. Divide the blowing and action in the air pressure diagram of the machine into three parts to meet the blowing and mechanical actions of different air pressures.

7. Strong clamping force, high pressure, double crank connecting rod clamping.

8. Operation mode: manual.

9. Safe and reliable, the unique valve position design makes the air pressure diagram of the machine easier to understand.

10. Low cost, high efficiency, simple operation, convenient maintenance, etc.

11. Avoid bottle contamination.

12. The cooling effect of the bottle mold cooling system is ideal.

13. Easy to install and start.

14. Low rejection rate: less than 0.2%.

15. Save labor, one person can operate the machine.

16. Adopt a new double curved arm and four-bar clamping structure (patented): horizontal; the middle template moves in parallel; the distance between the two templates is adjusted by the sprocket. Therefore, the clamping force is very strong.

17. Power-saving design, can increase your profit.

18. Separate air control system to avoid waste pollution.

if you have any requestSemi-automatic blow molding machine, welcome to contact me! ! !

main products

VIEW MORE

YOU MAY LIKE