Additional Service Inspection/Chongqing Vehicle Inspection

- $138.00 /piece

- 1 piece

- Nantong Leno Inspection Technology Co., Ltd.

- Jiangsu, China

- Mr Jason Gu

PRODUCT DETAIL

| Inspection place: | China city | Problem reporting time: | within 24 hours |

| Senior Inspector: | More than 10 years of experience | Origin: | Jiangsu, China |

| brand: | leno check | Packaging Details: | According to international inspection standard (AQL) and customer's special inspection requirements |

| Inspection before shipment: | professional report | service hours: | 7x24 hours |

| Report language: | English | Service type: | Final inspection service |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | model: | Third-party inspection agency |

| Third party inspection: | Independent inspection Highly professional QC service | Supply capacity: | 30 cases |

| Delivery Details: | within 24 hours |

Product Description

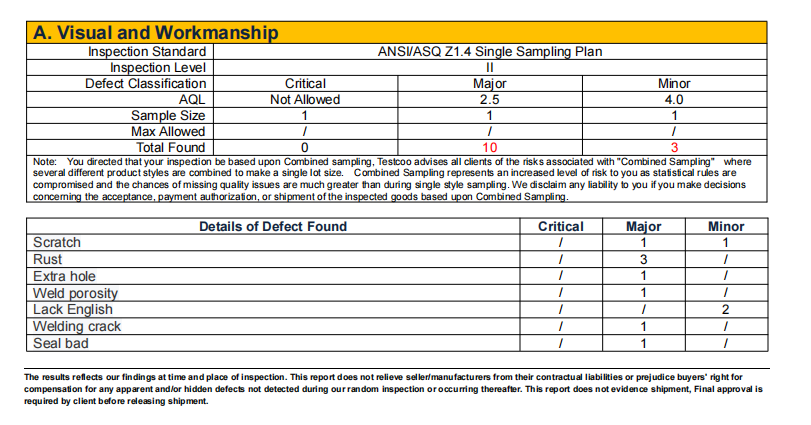

workmanship inspection

Process inspection is the most important part of product inspection. The general inspection standard is in accordance with the AQL standard, in the form of ANSI/ASQZ1.4 (MIL-STD-105E). For the sample size and

For defect acceptance, if there are no special circumstances, use level II, serious level is 0, major is level 2.5, slight is level 4.0

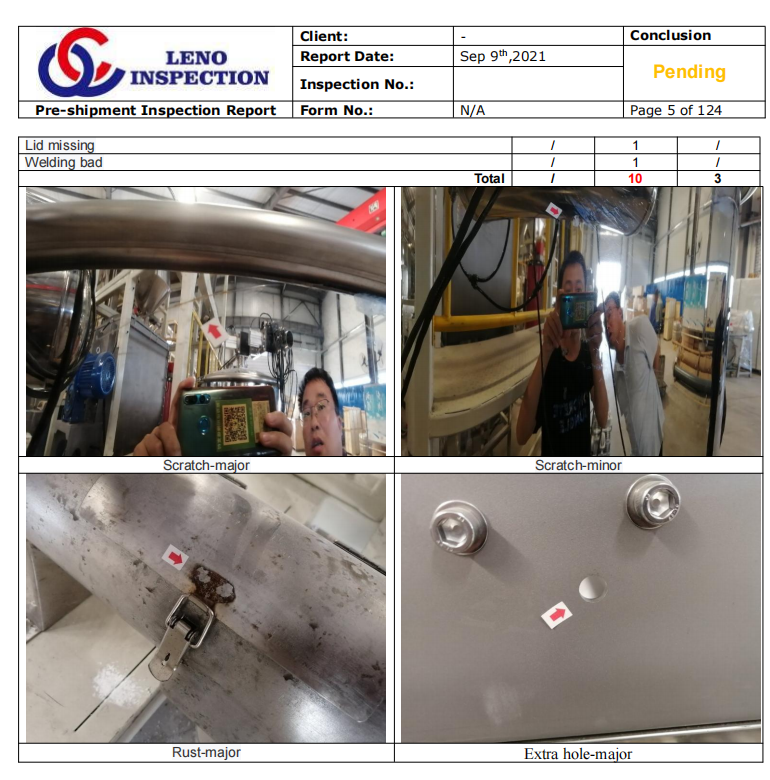

customer's request. All defects will be documented in a report and detailed photos with captions will be taken. You can refer to the photos below. We will give a result (pass/fail) for that part based on the criteria and number of defects. All defects will be picked out by inspectors and supervise factory rework.

For defect acceptance, if there are no special circumstances, use level II, serious level is 0, major is level 2.5, slight is level 4.0

customer's request. All defects will be documented in a report and detailed photos with captions will be taken. You can refer to the photos below. We will give a result (pass/fail) for that part based on the criteria and number of defects. All defects will be picked out by inspectors and supervise factory rework.

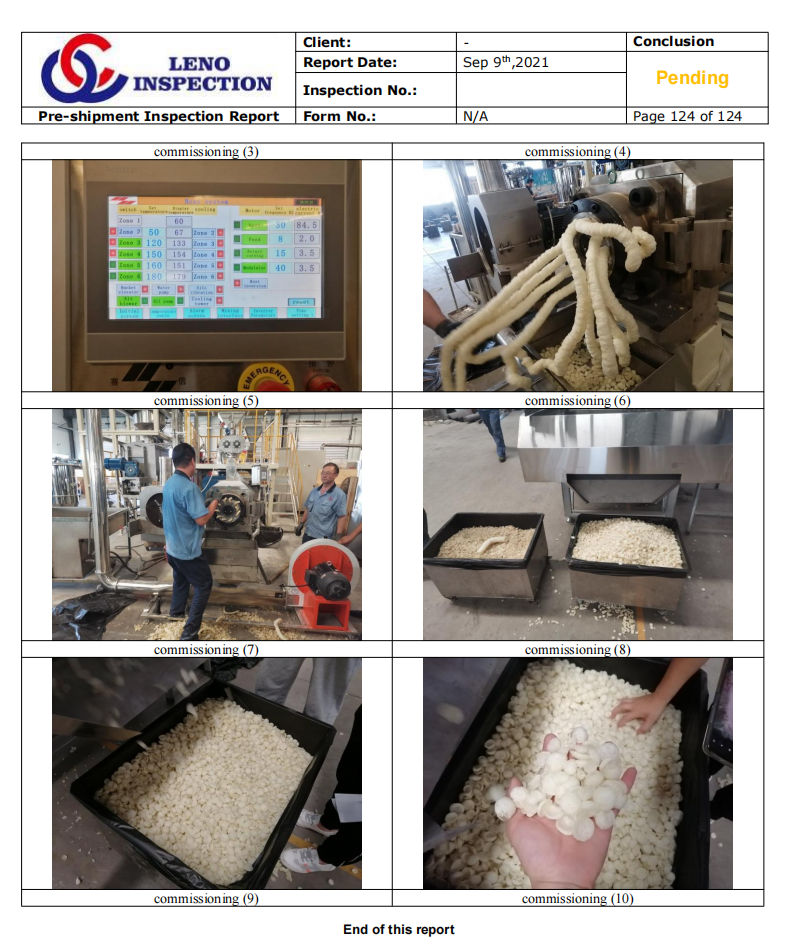

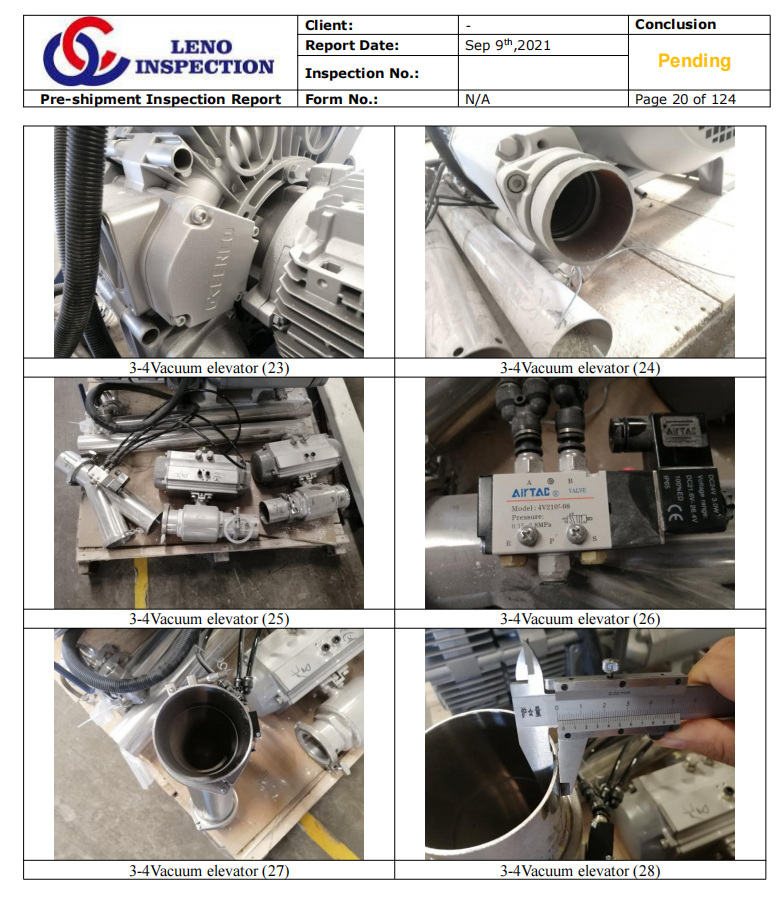

3. Field test

On-site testing is to check the function, performance and parameters of the product. We use different test items for different products. All test items will be confirmed with you before the test, you can decide the final test items, and we will also give you some reasonable suggestions for your reference.

Here we have selected a few test items to give you a better understanding of the testing part of the inspection process. Please refer to the picture below:

Here we have selected a few test items to give you a better understanding of the testing part of the inspection process. Please refer to the picture below:

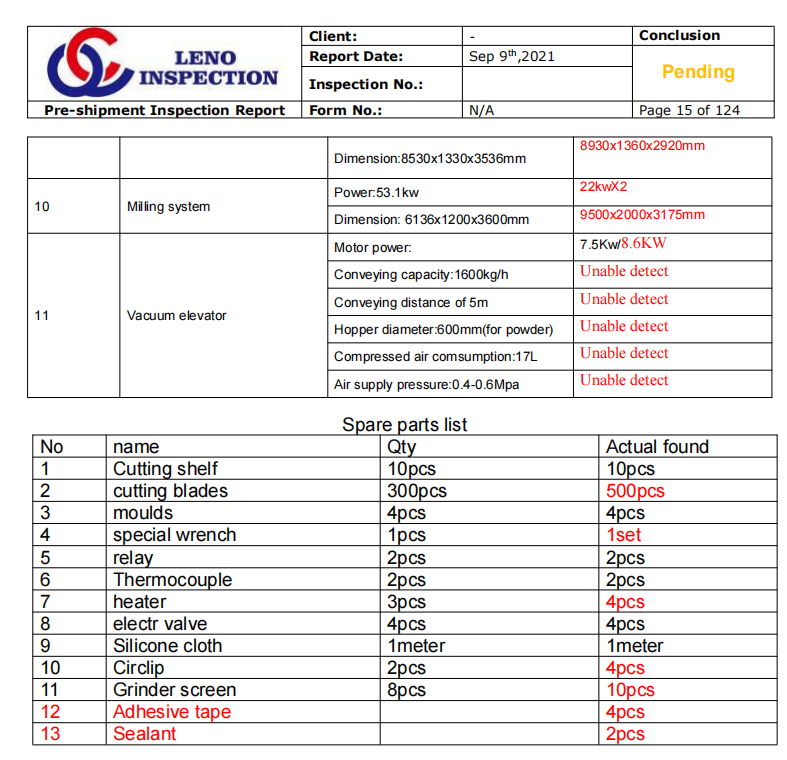

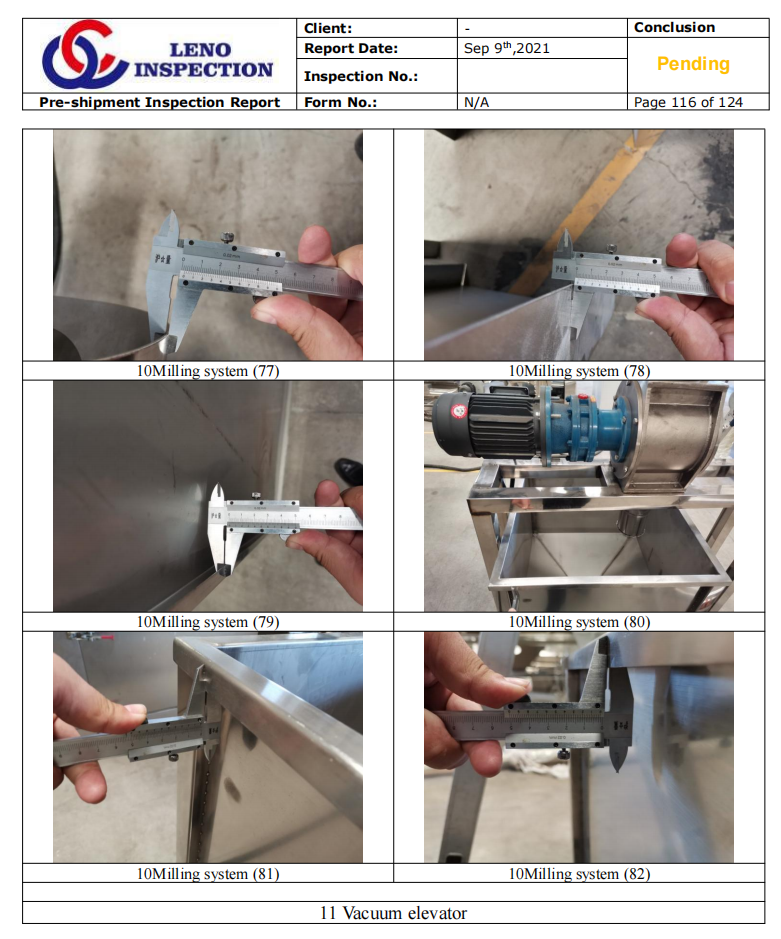

4. Measurement inspection

Measurement checks include package size and weight checks and product size and weight checks. All measurement information is recorded in a report, as shown in the figure below.

Customer's special requirements

In order to better inspect the products, in addition to the above four inspection items, we also accept other reasonable requirements from customers. Just like a sealed sample, provide some critical feedback on the spot...all your worries will have results.

A report will be issued within 24 hours after the inspection.

VIEW MORE

YOU MAY LIKE