Wuhu used car dropshipping service/trade assurance service/quality control product inspection

- $168.00 /piece

- 1 piece

- Nanjing Wei Pu Quality Inspection Technical Service Co., Ltd.

- Jiangsu, China

- Ms Bonnie Ji

PRODUCT DETAIL

| model: | car | brand: | we prove |

| payment terms: | trade assurance | Service type: | Honor Professional Apparel Textile Pre-shipment Inspection |

| payment terms: | D/P, D/P, T/T | Inspection before shipment: | transportation |

| Third party inspection: | Independent inspection Highly professional QC service | Production monitoring: | Continuous valuable feedback |

| Senior Inspector: | More than 10 years of experience | Packaging Details: | The report sent within 24 hours mainly includes: quantity inspection, workmanship inspection, product size and weight, product performance parameters, product color, outer box size, various labels and LOGO, etc. |

| Inspection place: | China city | Origin: | Wuhu |

| Problem reporting time: | within 24 hours | inspection report: | Detailed inspection report |

| service hours: | 7x24 hours |

Product Description

third party inspection | Independent inspection Highly professional QC service |

Check type | Pre-production/during production/pre-shipment inspection |

check location | Chinese cities and Vietnam |

inspection report | Provide detailed inspection report in English within 24 hours after inspection |

1. Why is shipment inspection or factory audit required?In case of any poor quality, incorrect shipment, untrue supplier information. Inspections and audits are the most effective way to protect buyer's rights.2. How to make an appointment for inspection?- Customers send us inspection inquiries 2-3 days in advance. We contact the factory to confirm the inspection. -Customer confirms the inspection plan and pays. Then we inspect and feed back the inspection report within 12 hours after the inspection.3. What do we need to offer you for inspection?- Factory contact number - Product information and your special quality control requirements (if any). - Some customers will also send approved samples.4. What information does the inspection report include?Our written reports are very detailed and include accurate descriptions of all defects and inconsistencies, statistical analysis based on highly recognized AQL standards and extensive on-site pictorial illustrations. Written report + detection video + original image provided 24 hours after detection5. What is the inspection rate?The general inspection rate for most coastal cities is USD 168.00/person-day. The specific inspection rate depends on the product type, order quantity and inspection address. This quotation includes all expenses: travel expenses + inspection fees + report fees. No other fees are required. Our maximum workload in 1 day is about 6 hours.6. What payment methods do we accept?Bank transfer, Paypal or Alibaba trade order. Inspection fees always require 100% prepayment prior to inspection.

Service Introduction

FA/SA

mainly include:

Supplier Legality:

Business license; house property certificate; export license; basic bank account and collection account, etc.

Production capacity:

Factory area, production equipment, personnel and storage area, etc.

QC:

Quality control program documents and the degree of performance of the quality department.

Supplier Legality:

Business license; house property certificate; export license; basic bank account and collection account, etc.

Production capacity:

Factory area, production equipment, personnel and storage area, etc.

QC:

Quality control program documents and the degree of performance of the quality department.

PSI/DPI

mainly include:

Quantity inspection, workmanship inspection, product performance (testing), measurement and customer's special requirements.

Pre-shipment inspection refers to the inspection performed when all goods are produced and packaged. by carrying out

Sampling inspection is carried out in accordance with AQL standards to conduct a comprehensive assessment of the quality of the goods.

Quantity inspection, workmanship inspection, product performance (testing), measurement and customer's special requirements.

Pre-shipment inspection refers to the inspection performed when all goods are produced and packaged. by carrying out

Sampling inspection is carried out in accordance with AQL standards to conduct a comprehensive assessment of the quality of the goods.

CLC/CLS

mainly include:

Check the quantity of product loaded, the condition of the container (cleanliness, moisture, rust, holes, etc.).

And monitor the loading process to make sure no damaged products and outer boxes are loaded into the container.

Also remind the factoryReinforced productsWhen the container is not full.

Check the quantity of product loaded, the condition of the container (cleanliness, moisture, rust, holes, etc.).

And monitor the loading process to make sure no damaged products and outer boxes are loaded into the container.

Also remind the factoryReinforced productsWhen the container is not full.

inspection process

1. Quantity check

Usually, quantity inspection will be done during production inspection (DPI), pre-shipment/final inspection (PSI/FRI), full inspection and loading inspection (CLC). It includes carton quantity inspection and each inner packing inspection product. And for the final inspection, the product must be 100% finished, at least 80% finished.

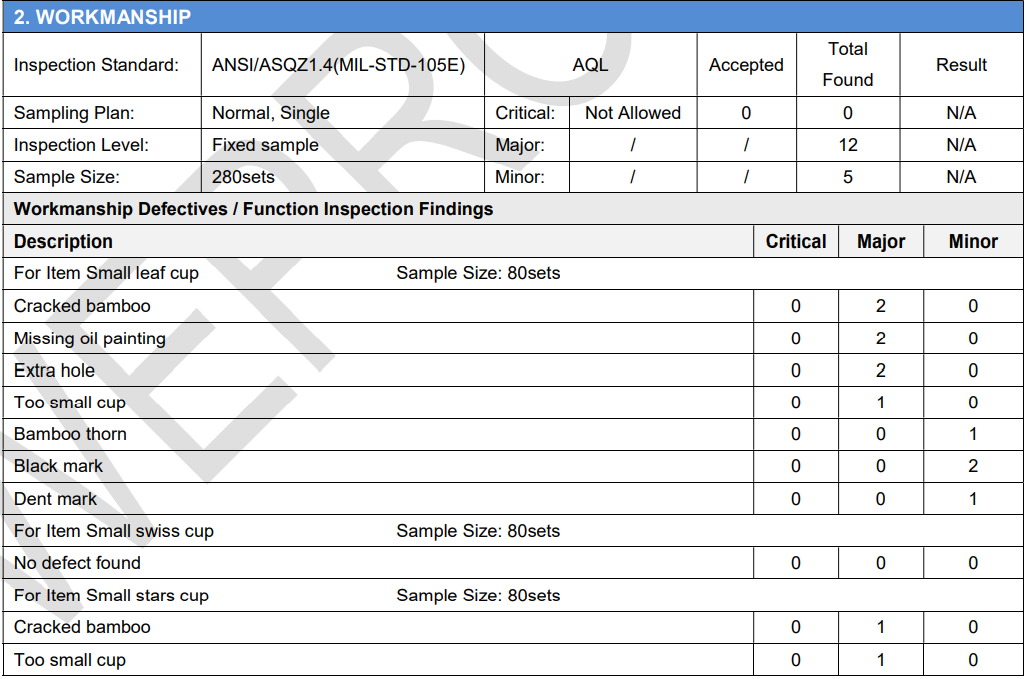

2. Workmanship

Workmanship is a very important part of the entire inspection process. If the number of defects is too high, FAIL will result.

The general inspection standard is in accordance with the AQL standard, in the form of ANSI/ASQZ1.4 (MIL-STD-105E). For sample size and defect acceptance, if the customer has no special requirements, use level II and level 0 Critical, the main level is 2.5, and the minor level is 4.0.

Please refer to the graph below from the report:

The general inspection standard is in accordance with the AQL standard, in the form of ANSI/ASQZ1.4 (MIL-STD-105E). For sample size and defect acceptance, if the customer has no special requirements, use level II and level 0 Critical, the main level is 2.5, and the minor level is 4.0.

Please refer to the graph below from the report:

3. Field test

Testing is the most important part of the inspection.

The main purpose is to test the basic functions, safety, durability and other properties of the product.

Test items vary by product category.

Here are some common test items for your reference:

The main purpose is to test the basic functions, safety, durability and other properties of the product.

Test items vary by product category.

Here are some common test items for your reference:

Carton drop test

Output voltage test

Pressure test

Assembly test

No-load speed test

barcode test

4. Packaging and product measurement

Typically, measurement checks include package size and weight checks and product size and weight checks.

The inspection quantity is 1 piece per piece, if the actual result is different from the specifications or requirements, the tolerance is 10% for the packaging and 5% for the product.

The inspection quantity is 1 piece per piece, if the actual result is different from the specifications or requirements, the tolerance is 10% for the packaging and 5% for the product.

Our advantage

VIEW MORE

YOU MAY LIKE